Method used for working process of printing technique controlling machine

A technology of working process and printing technology, applied to printing machines, general parts of printing machinery, printing, etc., can solve problems such as insufficient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

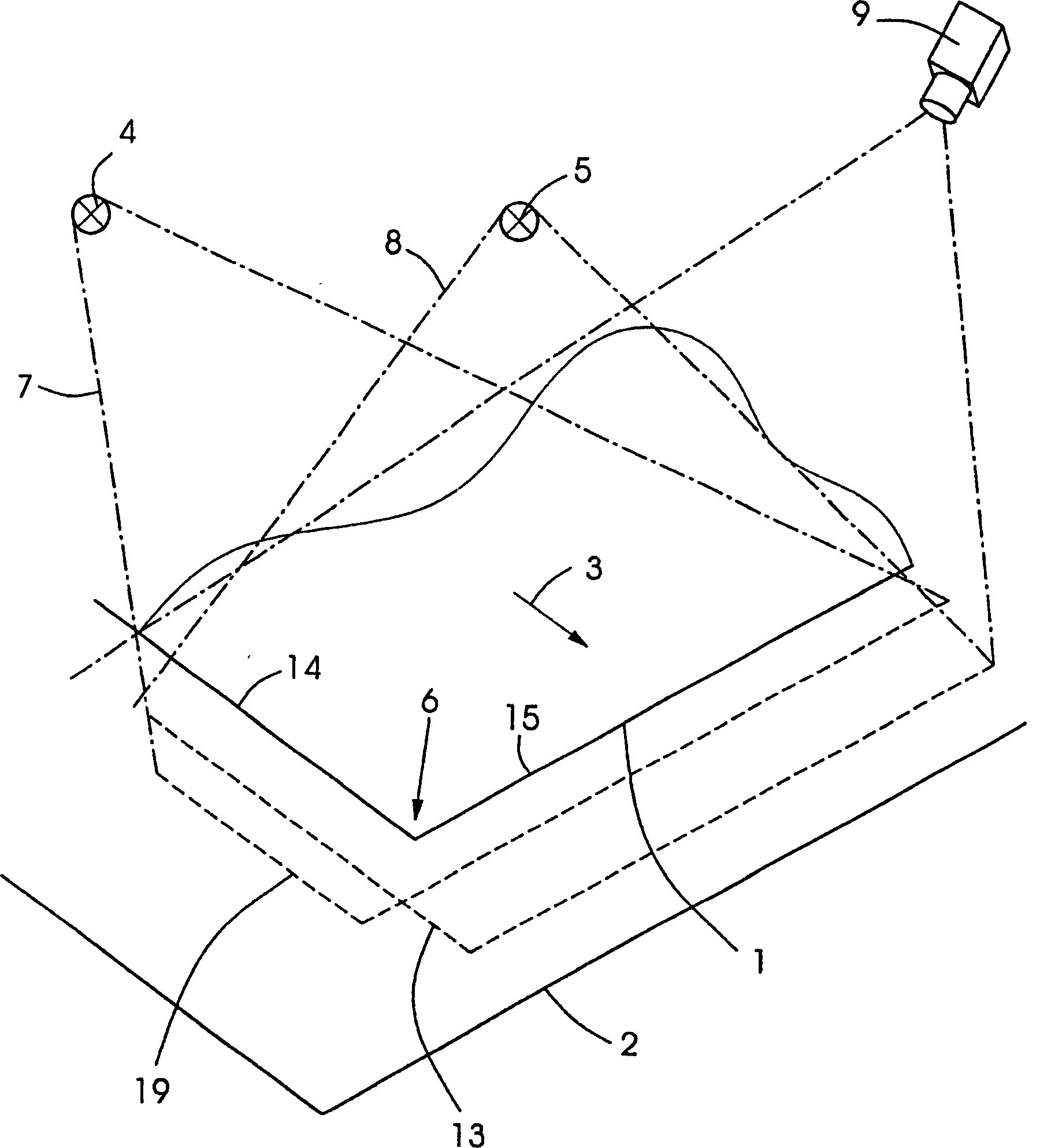

[0025] figure 1 The scene is shown during the transport of a sheet 1 in a printing press. During printing, the sheet 1 is moved by the transport device in the direction 3 past the sheet guide 2 without contact. Arranged above the sheet 1 along the transport path are two light sources 4 , 5 which illuminate a sheet corner 6 and its surroundings. These light sources 4,5 are fixedly arranged at different locations and generate light beams 7,8 of different wavelengths. In order to capture images of the scene, a color camera 9 is permanently arranged at a different location than the light sources 4,5.

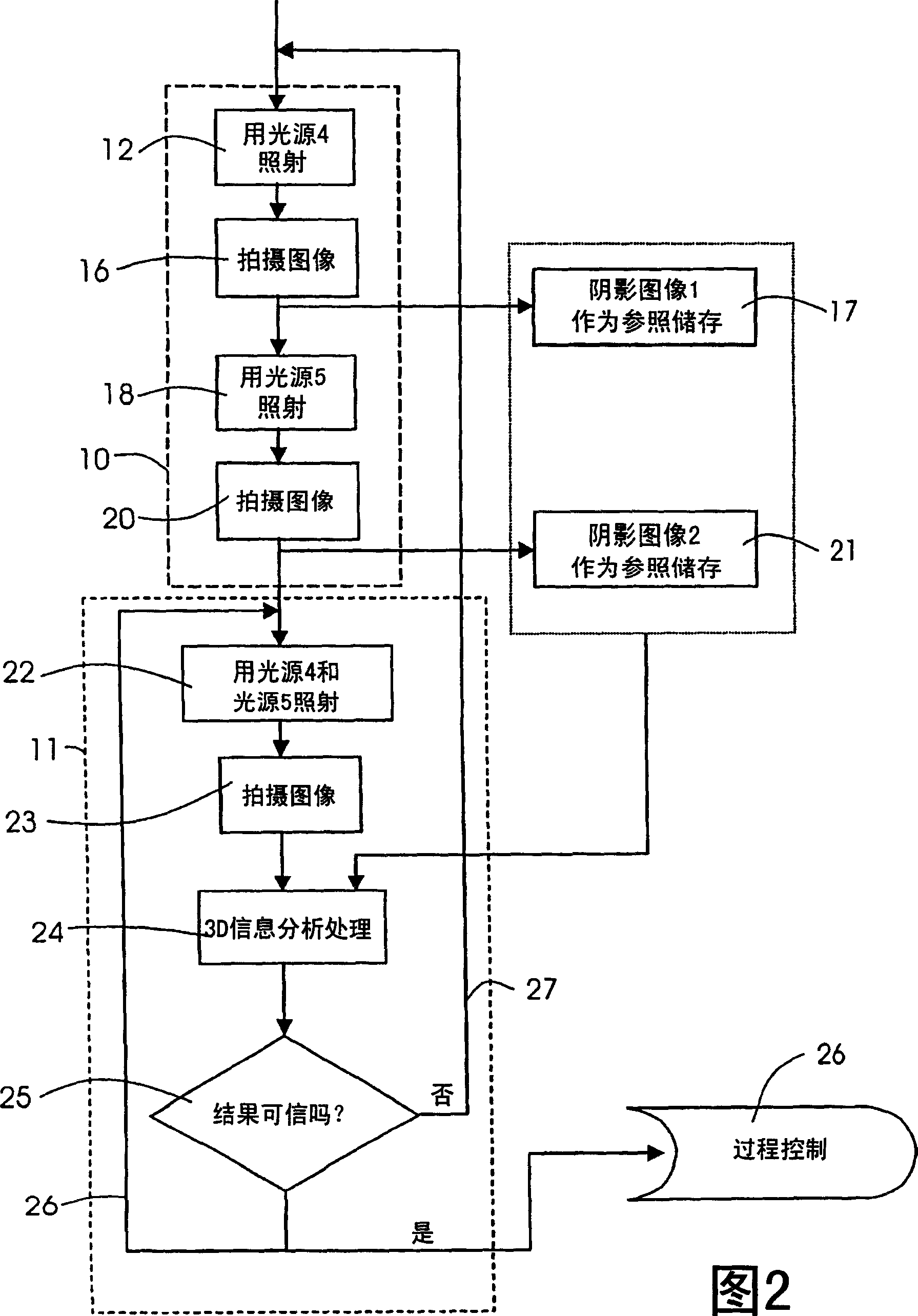

[0026] The implementation of the method is described below with reference to FIG. 2 . These method steps are subdivided into a study phase 10 and a working phase 11 , which are each framed in dashed lines in FIG. 2 .

[0027] In the learning phase 10 a sheet 1 is placed in a position above the sheet guide 2 for the learning record, which corresponds to a desired position during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com