Kitchen automatic smoke discharging device

A smoke exhauster, automatic technology, applied in the direction of oil fume removal, household heating, lighting and heating equipment, etc., can solve the problems of polluting the environment, the area of the smoke outlet of the smoke collection cavity, pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

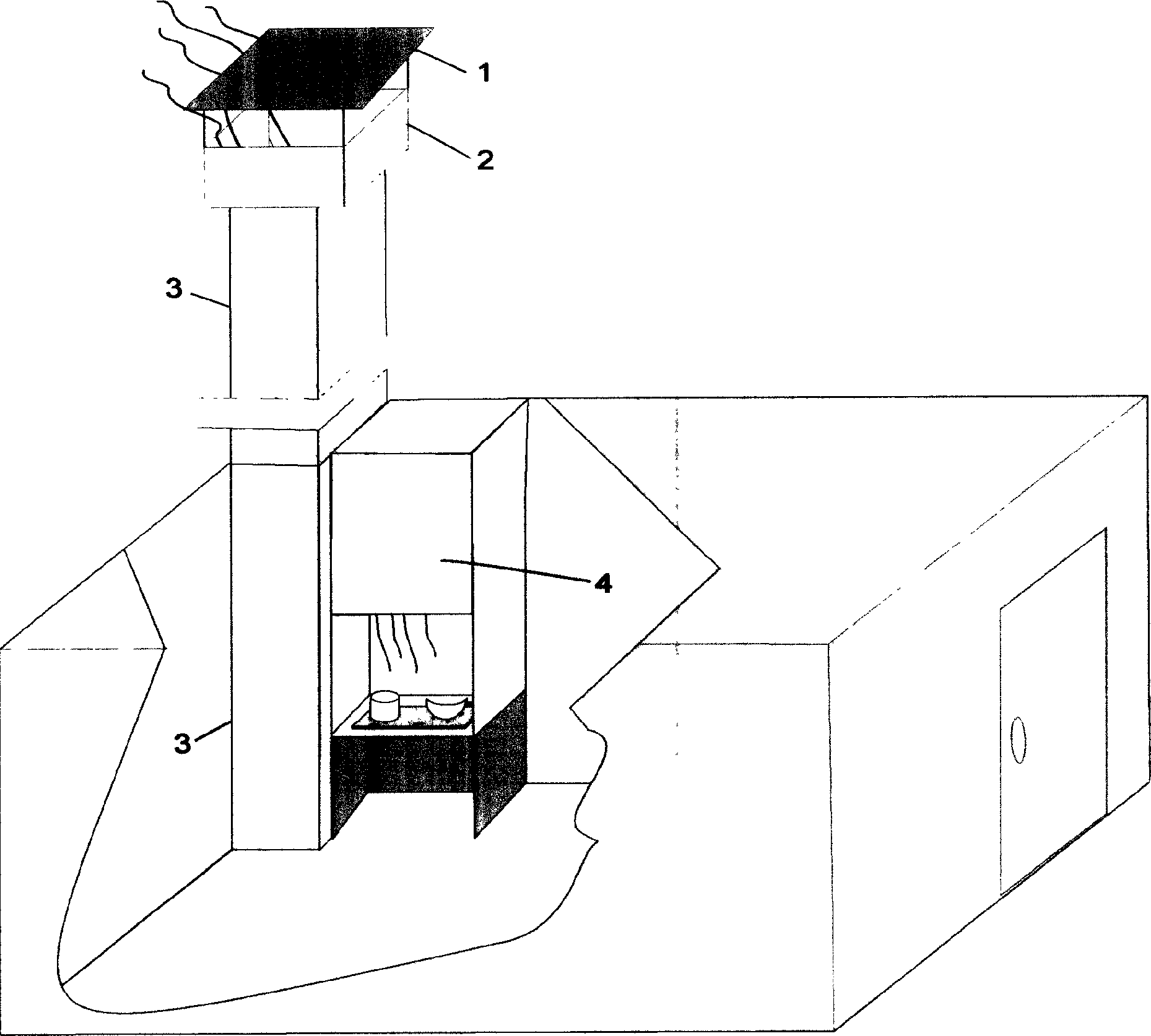

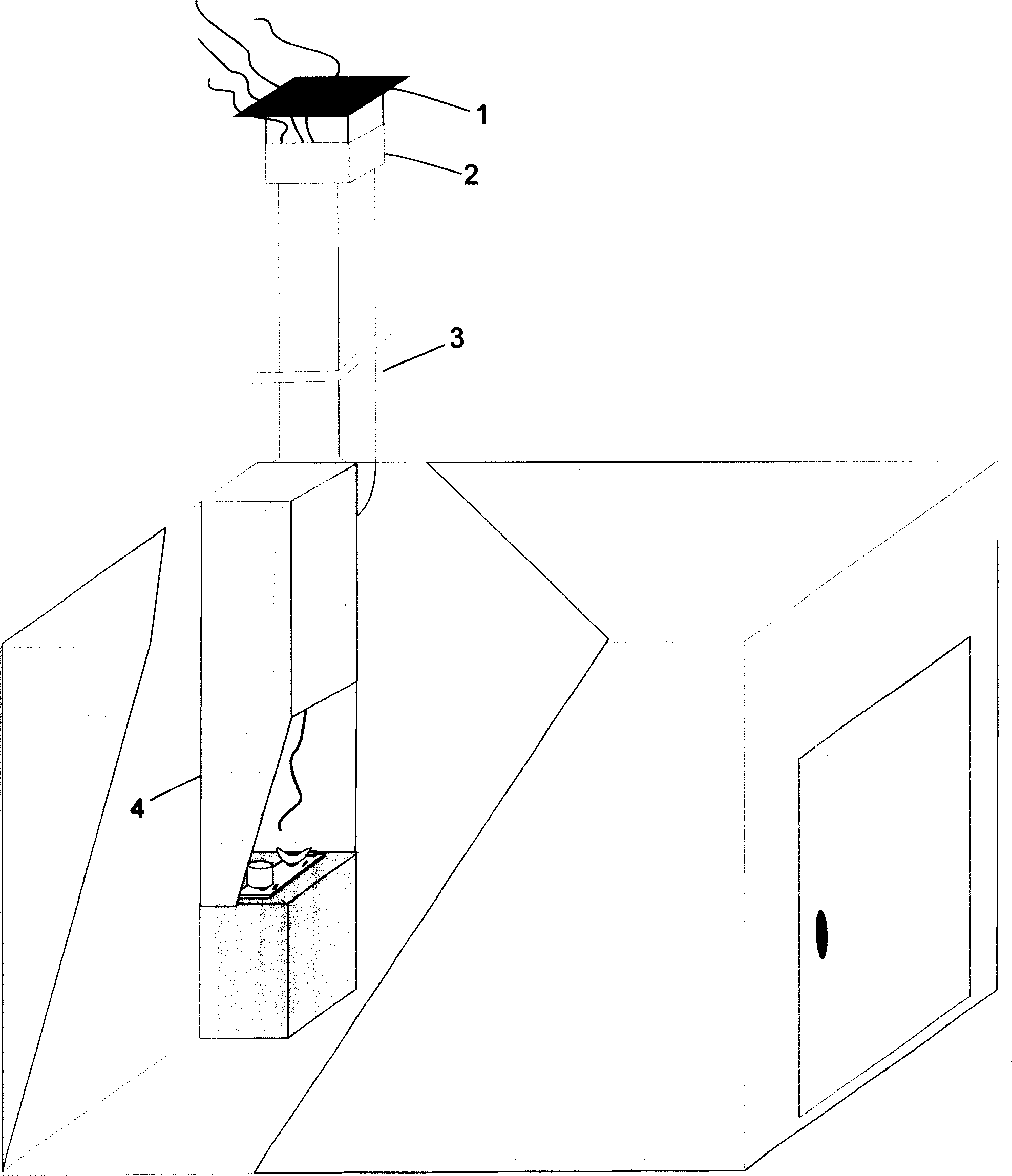

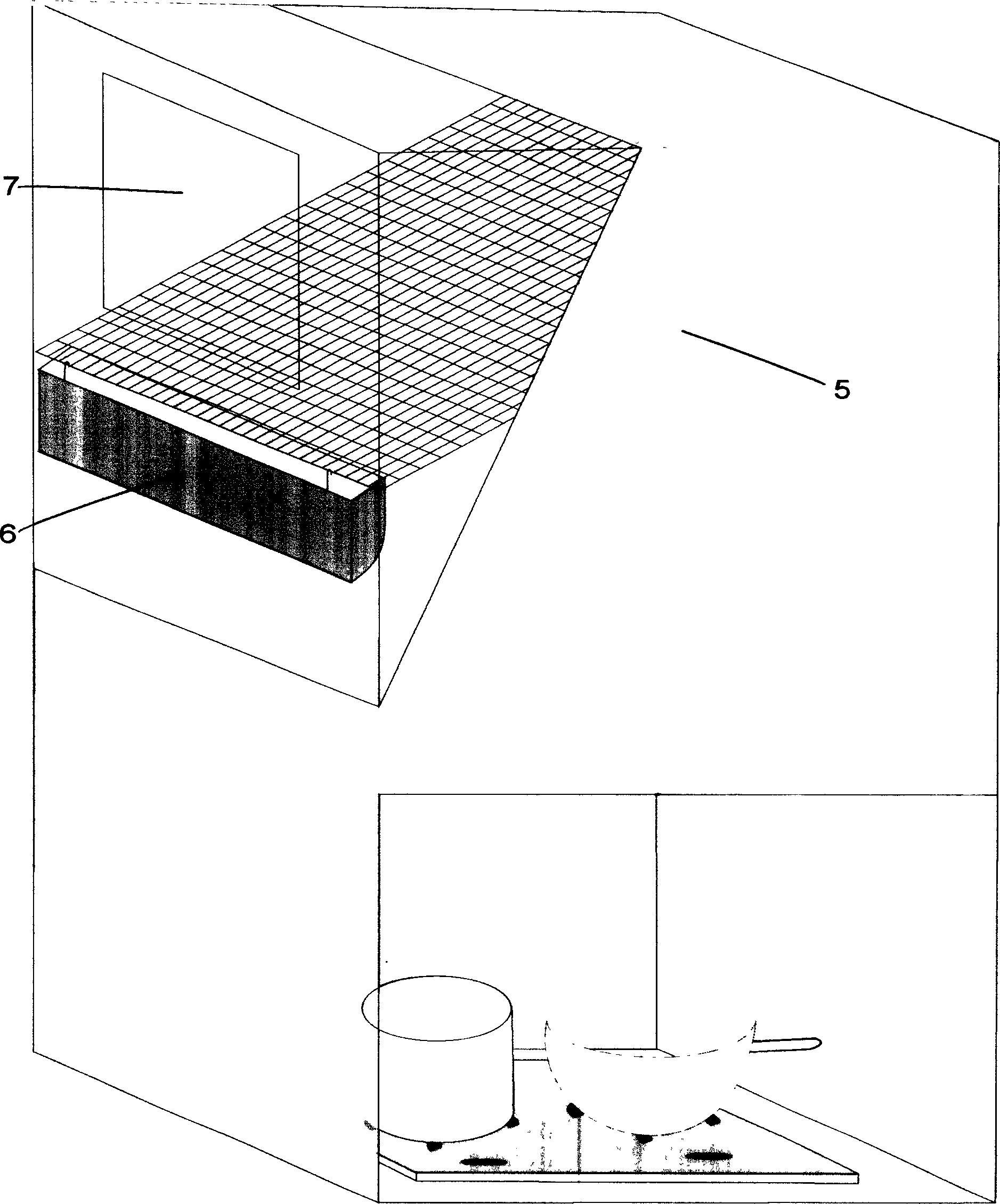

[0007] Figure 1A and Figure 2B show that the smoke collecting chamber 4 directly utilizes the walls on the back and side of the cooktop, and the other two sides are made of aluminum iron sheet or glass plastic board, and are installed vertically above the cooktop and connected with the side walls. As a whole, the surrounding gaps are sealed; the height of the smoke inlet on the front of the cooking operation of the smoke collection chamber is subject to not hindering the cooking operation and the oil fume from rushing into the entrance of the smoke collection chamber by its own power, (the lower the height of the smoke inlet, the lower the height of the smoke inlet. The stronger the smoke collection and smoking function), the height of the smoke collection chamber is from the entrance to the top of the house, the width is the same as the width of the stove, and the length is based on the fire on the stove. flue) is a thin brick wall structure, the smoke inlet of the public flue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com