Resistive suction muffler for refrigerant compressors

A muffler and refrigerant technology, applied in the direction of machines/engines, mechanical equipment, liquid variable capacity machinery, etc., can solve problems such as bearing deterioration and decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

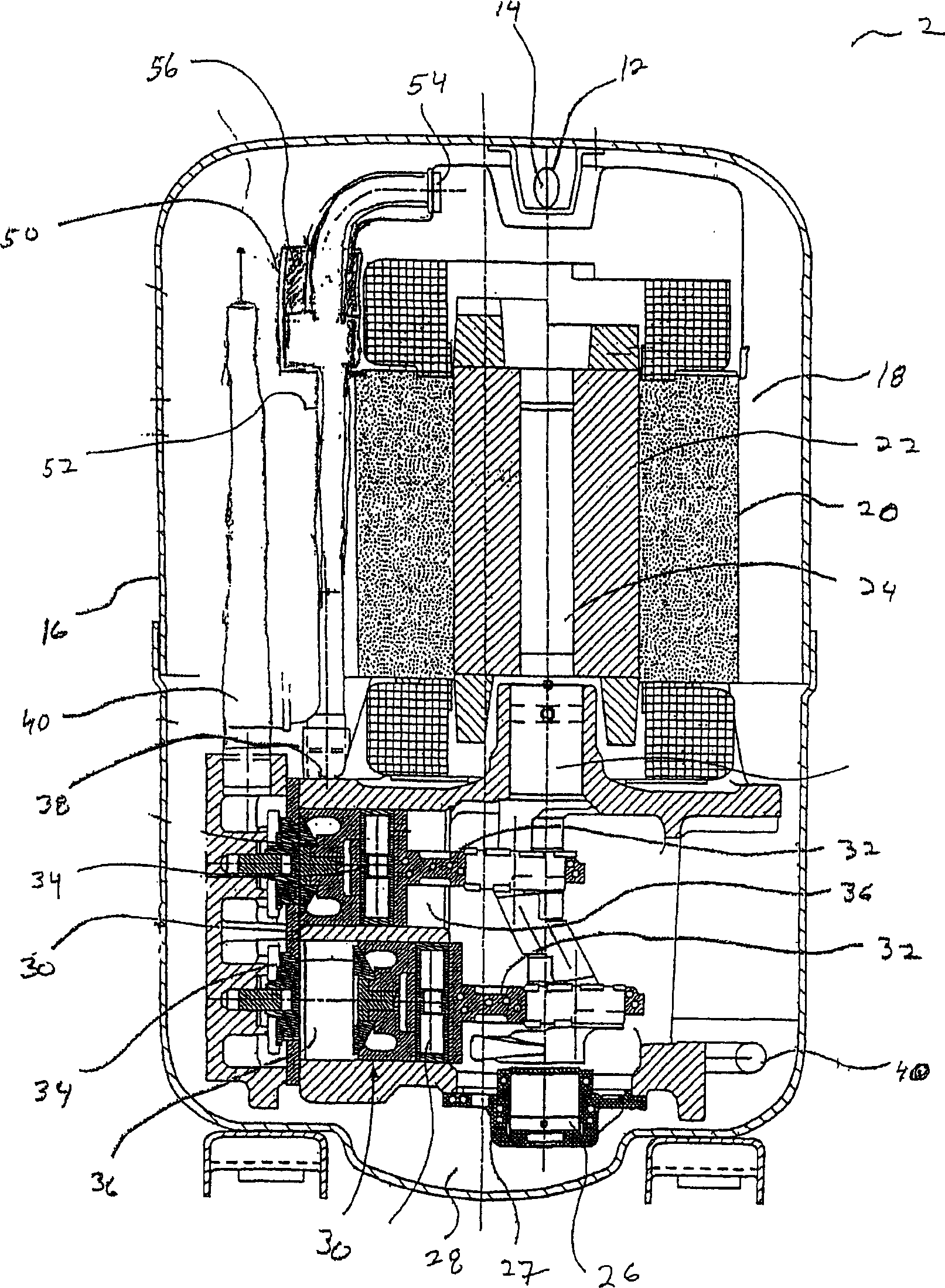

[0021] exist figure 1 A compressor equipped with an impedance type muffler of the present invention is shown in . The compressor 2 is connected to a conventional refrigeration system (not shown), such as may be the system in a domestic or car refrigerator, having a condenser, expansion valve and evaporator and piping connecting them together. The compressor 2 is a reciprocating compressor, which is connected to an evaporator (not shown) through a suction pipe 12 inserted into a suction port 14 of the compressor 2 . A suction port extends through the compressor housing 16 . Refrigerant gas from the evaporator enters the low pressure side of the compressor 2 through the suction port 14 .

[0022] Compressor 2 includes an electric motor 18 . Illustrated is a standard induction motor having a stator 20 and a rotor 22 . However, any other type of motor can also be used. A shaft 24 extends through the rotor 22 . In this compressor 2 the bottom end 26 of the shaft 24 extends in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com