Oil well casing reconditioning tool

An oil well casing and subsidy technology, applied in wellbore/well parts, earthwork drilling and production, etc., can solve the problems of large contact area, high requirements, and high hydraulic system pressure, and achieve small contact area, reasonable structure and wide adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

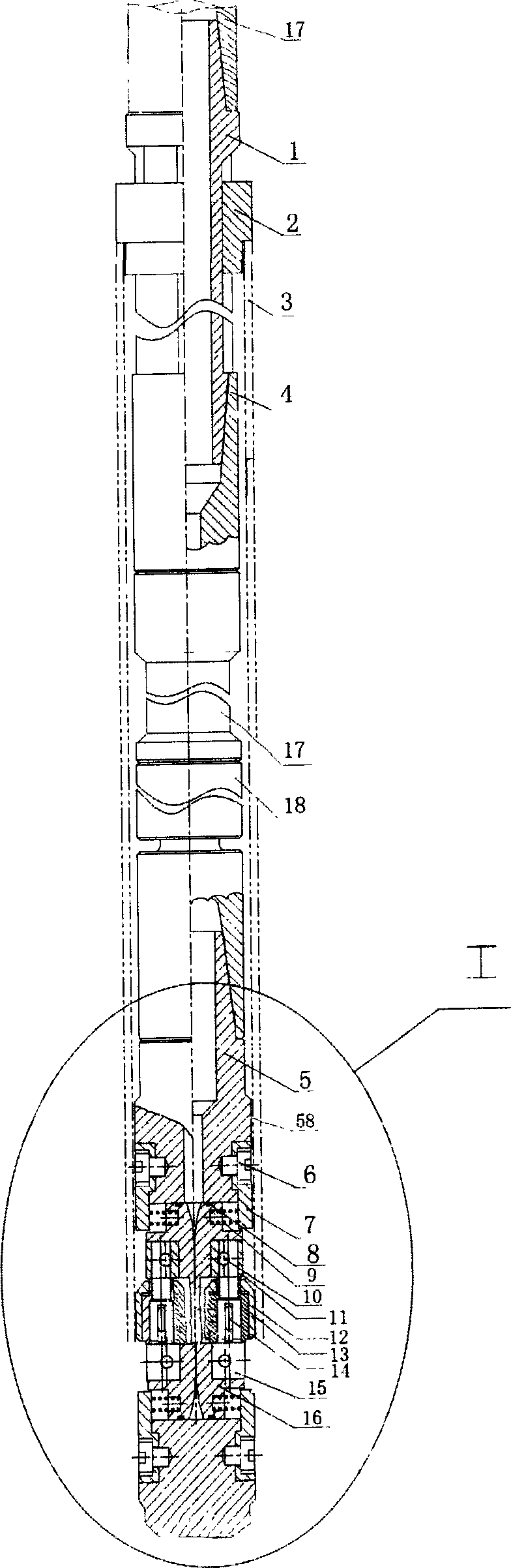

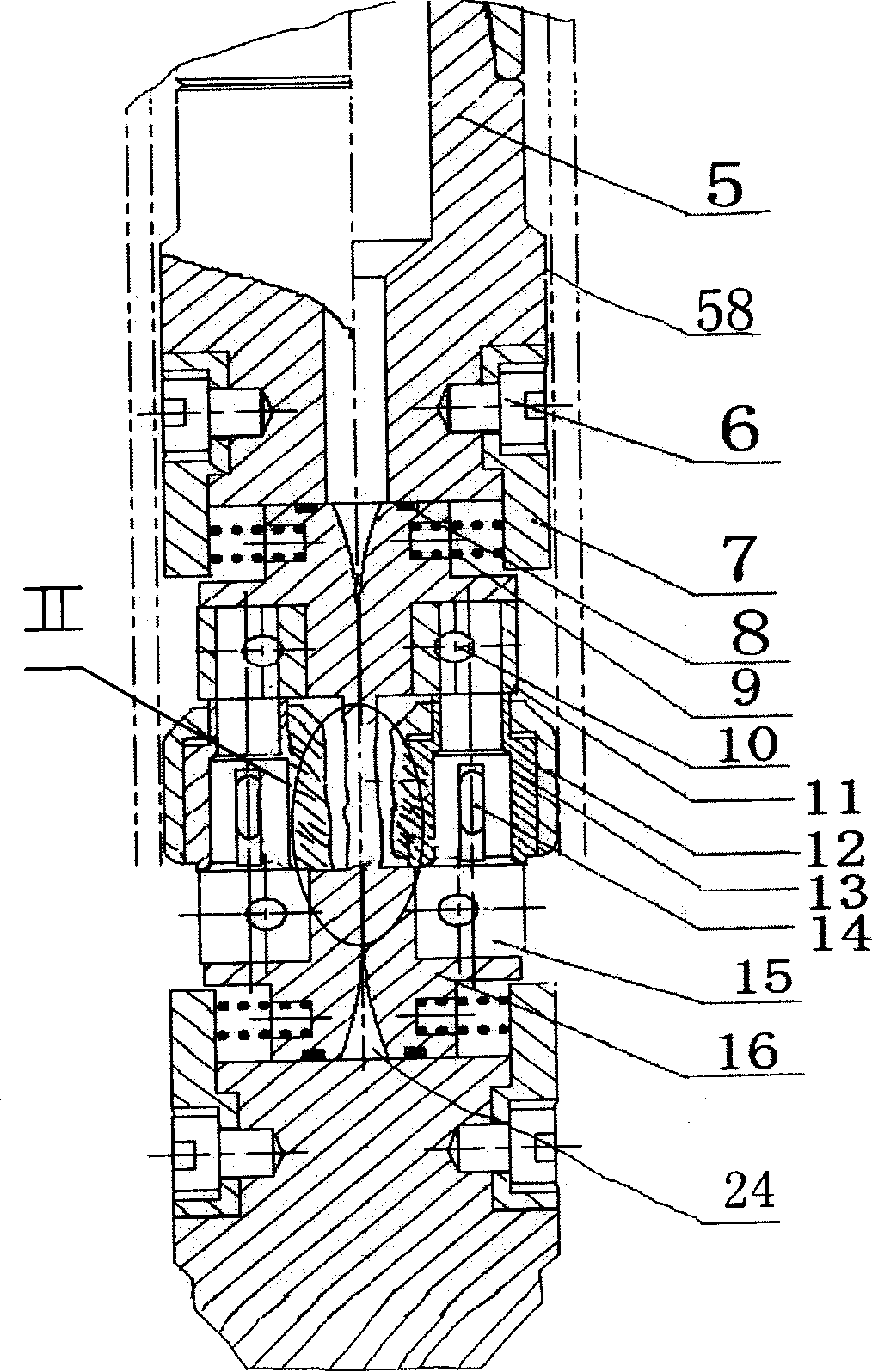

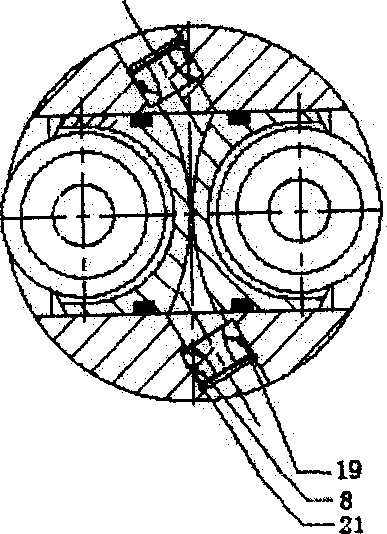

[0030] The following is attached with the manual figure 1 , Figure 1a , Figure 1b , Figure 2a , Figure 2b , image 3 The structure and working principle of the casing subsidy tool described in the present invention are further described:

[0031] First, let me explain the currently used bushing subsidy tools: image 3 As shown, there is a cone 59 inside the expansion tube 3, and the ground hydraulic system pushes the piston 16, and the piston 16 pushes the cone 59 to move forward along the axis of the expansion tube, and then squeezes the expansion tube 3 to deform it and cling to the damaged one. Casing, to achieve the purpose of subsidy.

[0032] in the attached figure 1 Under the working conditions, the expansion head 58, the downhole motor 18, the drill pipe 17, the sliding sleeve device, and the expansion pipe 3 are attached to the wellhead before work. figure 1 After the sequence is assembled, use the drill pipe 17 to connect with the upper part of the slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com