Internal combustion engine with cylinder lubricating system

A technology for lubrication systems and internal combustion engines, applied in the direction of pressure lubrication of lubrication pumps, control of lubricant pressure, timing lubrication, etc., can solve problems such as increased consumption of lubricating oil, difficulty in forming, sticking, etc., to avoid lack and prevent lubrication Effect of reduction in oil supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

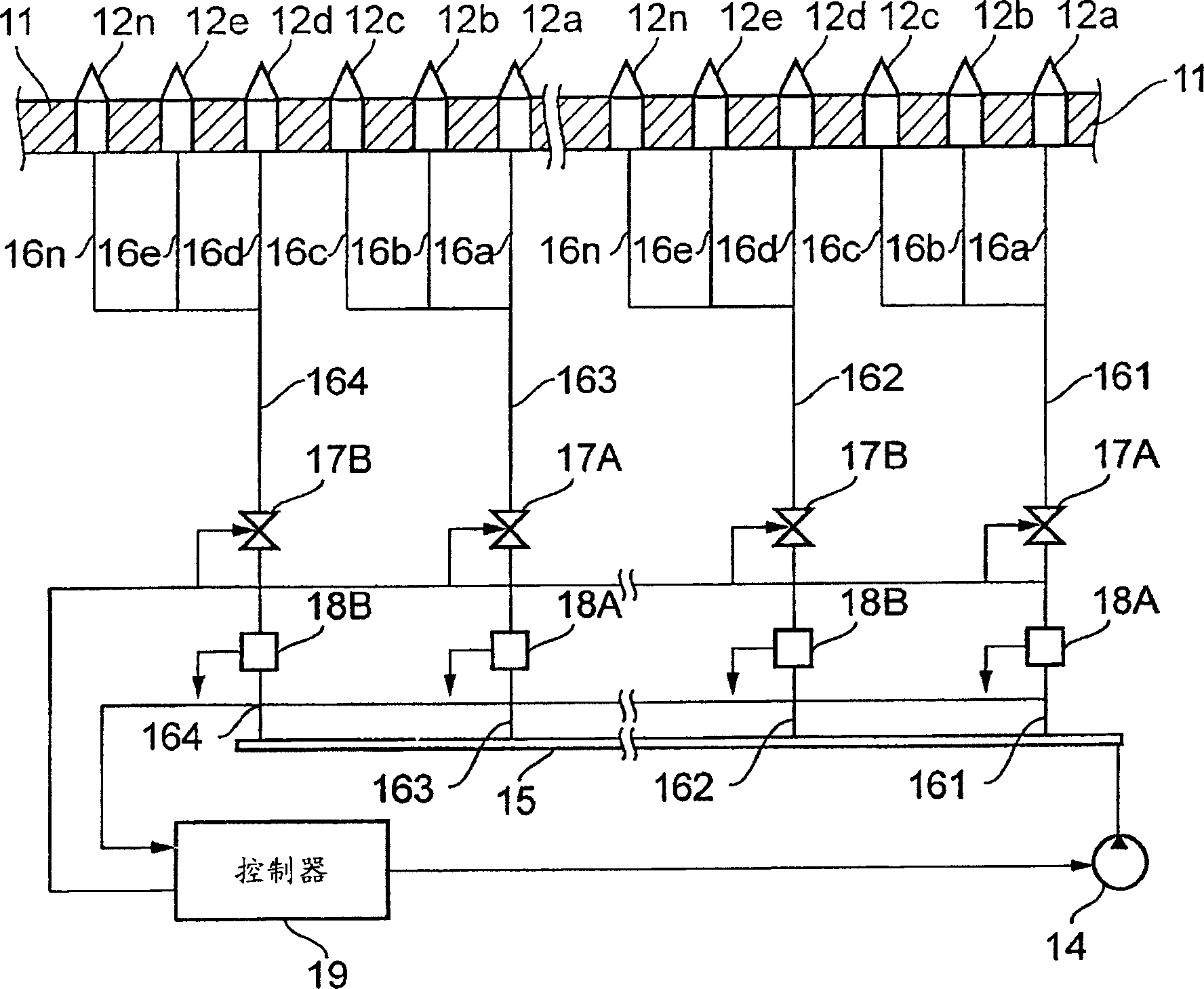

[0063] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. However, it should be understood that, unless otherwise stated, the dimensions, materials, corresponding positions, etc. of the components in the embodiments are merely illustrative examples, rather than limiting the scope of the present invention.

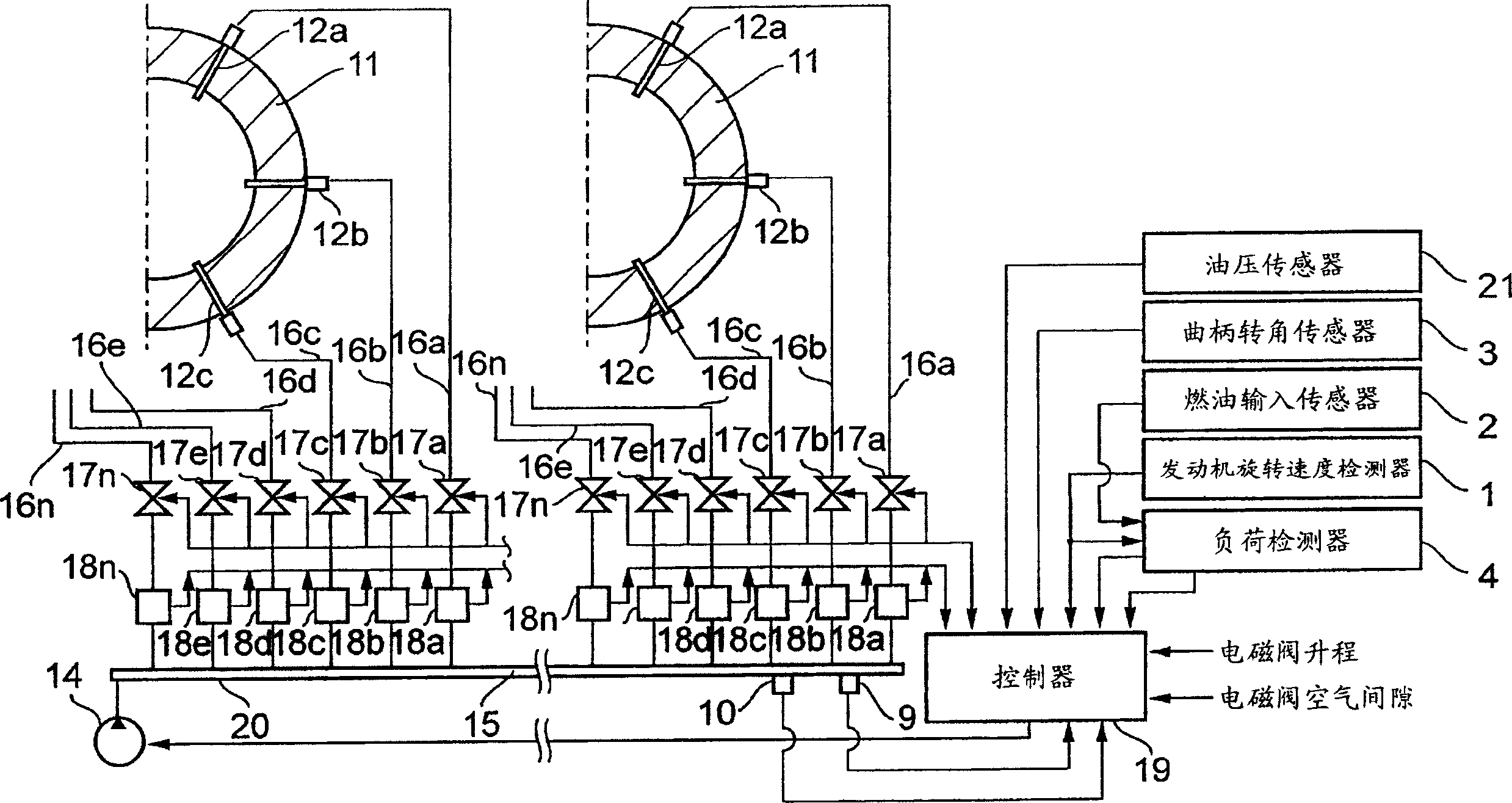

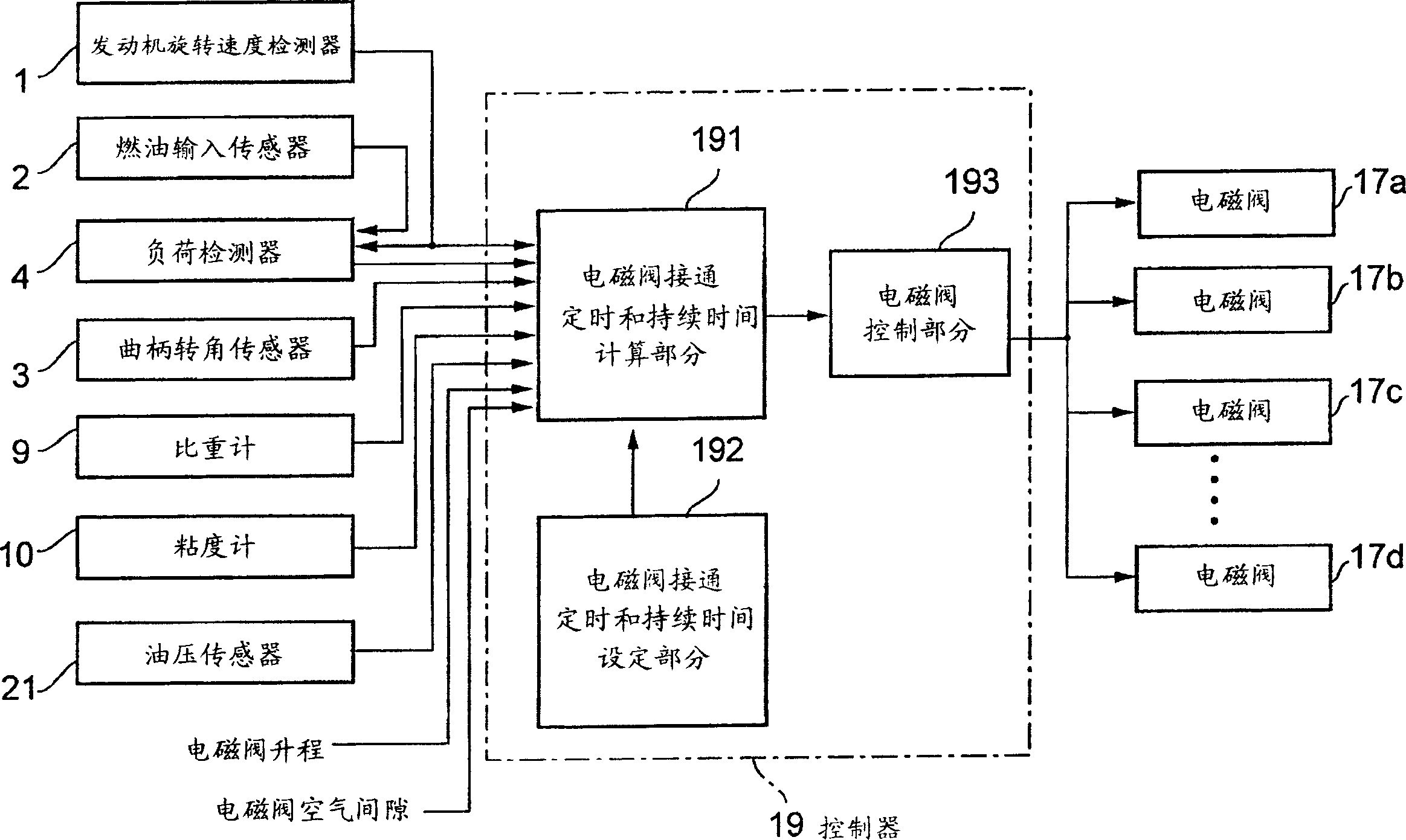

[0064] figure 1 It is the overall connection diagram of the first embodiment of the electronically controlled lubrication system of the present invention.

[0065] see figure 1 , reference numeral 11 is a cylinder liner, and two cylinder liners (cylinders) are shown in the figure. Reference numerals 12 a , 12 b , 12 c . . . , 12 n (omitted) are lubricators for supplying lubricating oil to the inner surfaces of the respective cylinders 11 . A plurality of lubricators 12a, 12b, 12c..., 12n are arranged along the circumference of each cylinder 11, preferably distributed at equal intervals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com