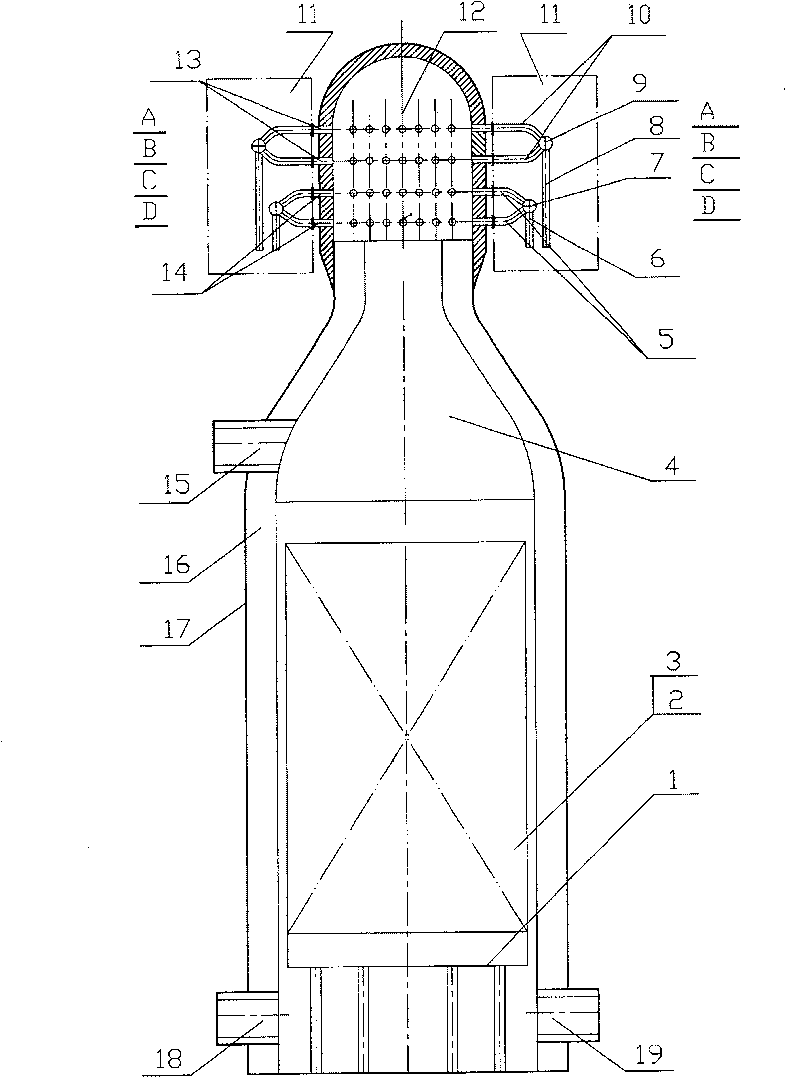

External distributor style top-burning hot-air furnace

A distributor and hot blast stove technology, which is applied in the field of top-fired hot blast stoves and external distributor type top-fired hot blast stoves, can solve the problems of large influence of temperature stress, complex structure, increased investment, etc., and achieves high hot blast temperature. , High thermal efficiency, sufficient combustion effect

Active Publication Date: 2010-05-12

SHANDONG PROVINCE METALLURGICAL ENG CO LTD

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Blast furnace smelting requires hot air with a high enough temperature. The hot blast stove is a device that provides this hot blast. The current industrial hot blast stoves include internal combustion type, top combustion type, ball type, and external combustion type. Among them, the top combustion type hot blast stove has different The structure, such as the hot blast stove with patent No. WO0058526 and WO03071555, has the disadvantage that the collector is arranged inside the pre-combustion chamber, which is not penetrating. The lining of the pre-combustion chamber is relatively thick, and the configuration of air and gas channels is limited. It is relatively complex, with many brick types, and the temperature stress has a great influence on the partition wall and inner vertical wall of the collector, which causes a series of problems such as increased investment and difficult construction. How to improve the existing various top-fired hot blast stoves and make breakthroughs, strengthen The mixing of air and gas, simplifying the structure, reducing the difficulty of construction and saving investment has become a concern of metallurgical workers

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0030] The basic idea of the present invention can be realized by various options, but it is relatively complicated to realize all functions, so it is the preferred solution to implement according to the embodiments in the accompanying drawings.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

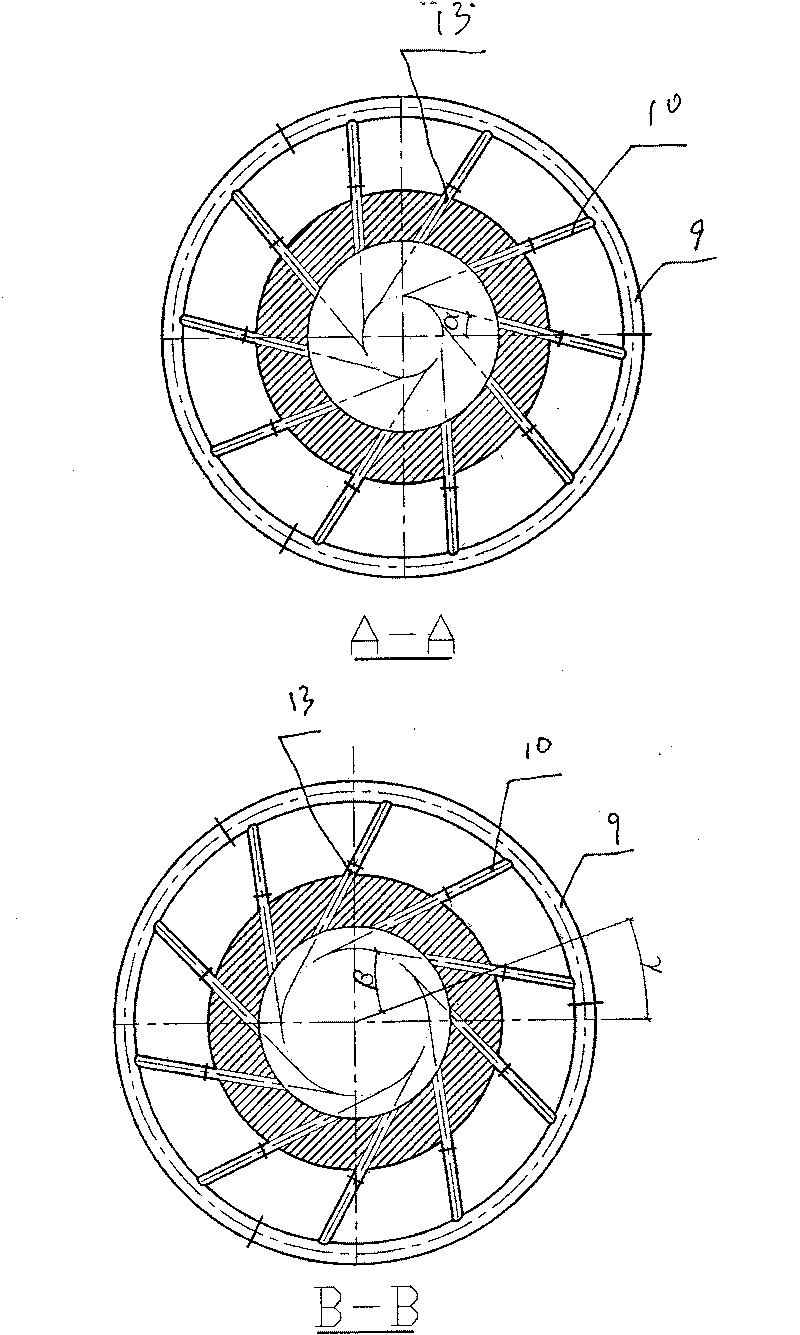

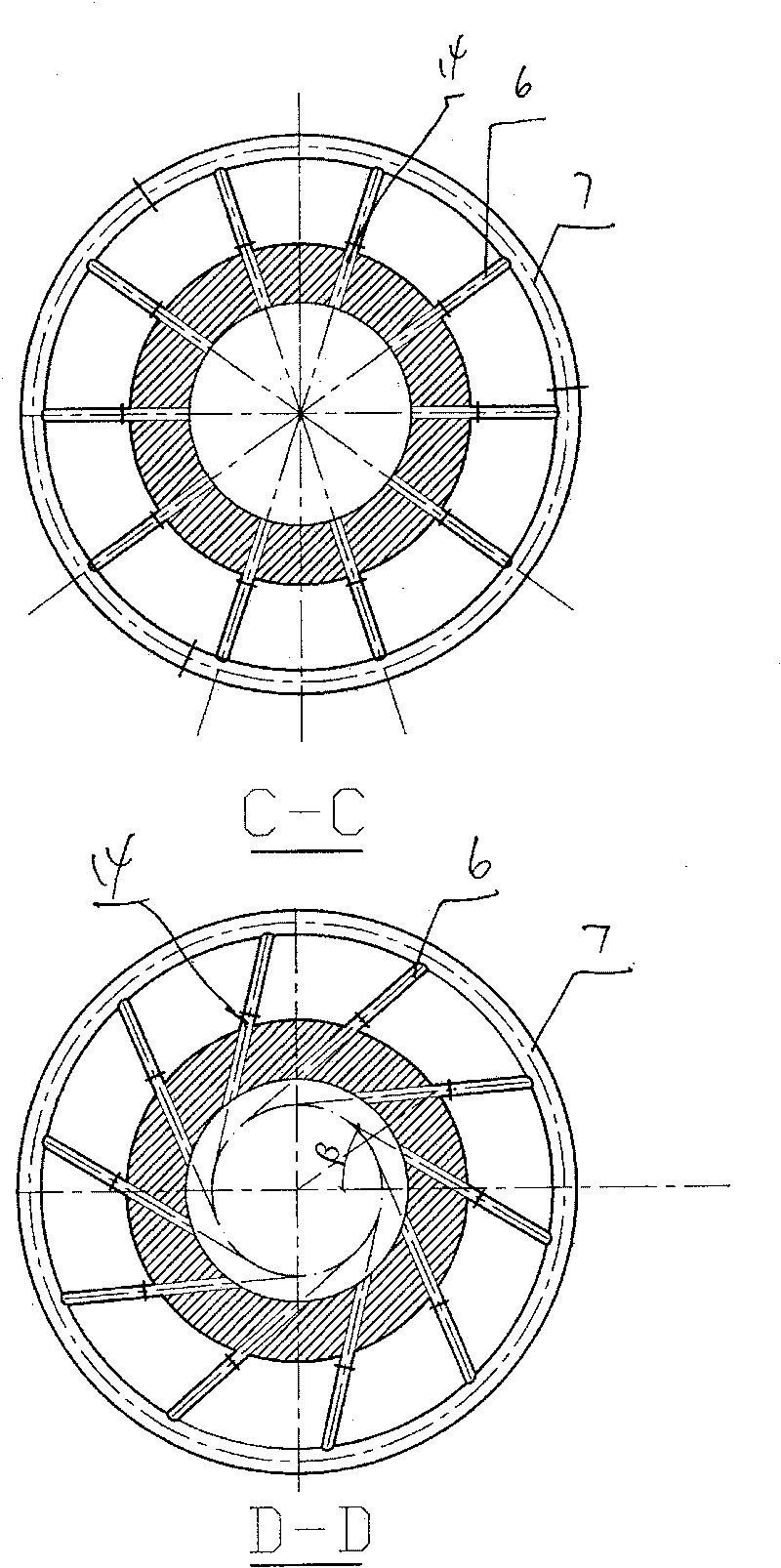

A outboard allocate hot-blast stove top gas burner. Fit mixing chamber on the top of blast chamber of air-stove. There are different air and coal gas penetrating ducts inside and outboard allotter outside of mixing chamber. Air and coal gas mix in mixing chamber throughout outboard allotter and coal gas penetrating ducts. Then diffuse to blast chamber.

Description

Technical field [0001] The invention relates to a top-combustion hot-blast stove in the field of blast furnace hot-blast stoves in metallurgical systems, and is a top-combustion hot-blast stove with an external distributor. Background technique [0002] Blast furnace smelting requires hot air with a high enough temperature. The hot blast stove is a device that provides this hot blast. The current industrial hot blast stoves include internal combustion type, top combustion type, ball type, and external combustion type. Among them, the top combustion type hot blast stove has different The structure, such as the hot blast stove with patent No. WO0058526 and WO03071555, has the disadvantage that the collector is arranged inside the pre-combustion chamber, which is not penetrating. The lining of the pre-combustion chamber is relatively thick, and the configuration of air and gas channels is limited. It is relatively complex, with many brick types, and the temperature stress has a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C21B9/00

Inventor 黄东生姚朝胜王荣恩

Owner SHANDONG PROVINCE METALLURGICAL ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com