Semiconductor substrate, semiconductor circuits formed there and manufacture thereof

A semiconductor and carrier substrate technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, circuits, etc., can solve the problems that electricity is easily affected by the contact area and the difficulty of semiconductor circuits is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

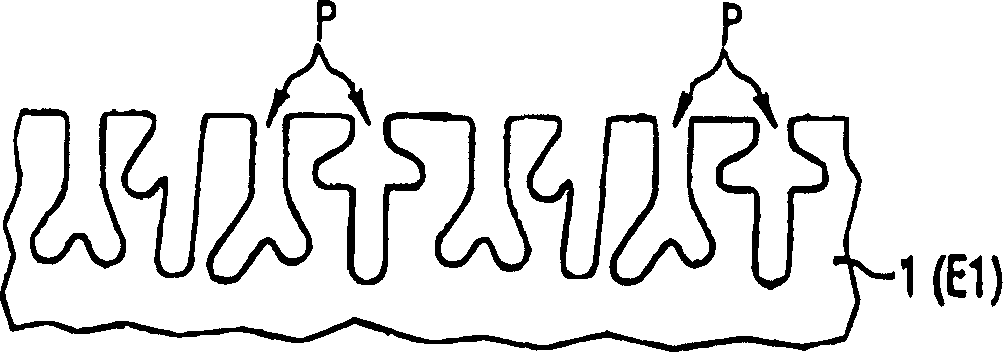

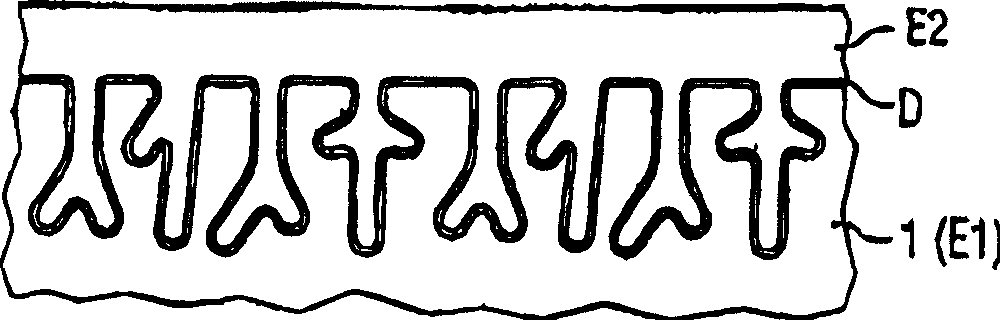

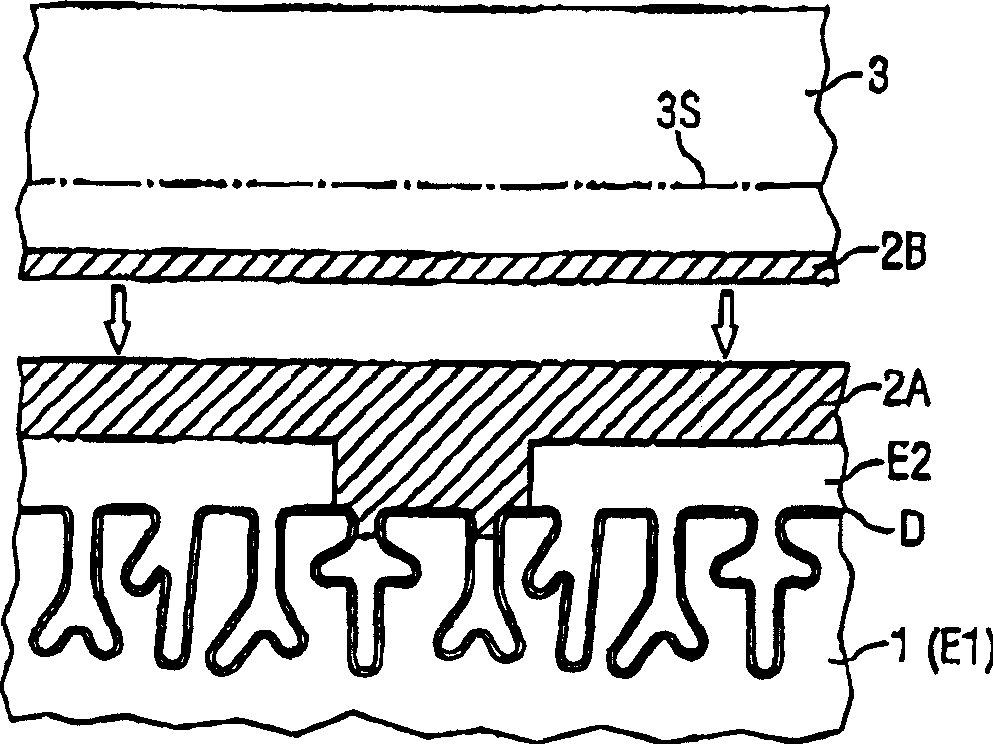

[0049] Figure 1A to Figure 1C It is a simplified cross-sectional view to illustrate the basic method steps of the semiconductor substrate manufacturing of the first embodiment of the present invention;

[0050] according to Figure 1A , multiple grooves P and a capacitor counter electrode E1 are formed in a carrier substrate 1, for example, it represents a semiconductor substrate, and preferably a silicon semiconductor wafer; preferably, multiple multiple pores P are formed to As the groove in the carrier substrate 1, it comprises n-doped silicon formed, for example, by electrochemical void etching, for example, the doping concentration of the carrier substrate is about 10 18 cm -3 , and first connected to a first voltage terminal and soaked in a hydrofluoric acid solution (25% by weight), while an electrode connected to a second voltage terminal is placed in the hydrofluoric acid solution. Then, generate a voltage of about 2 volts between the first voltage terminal and the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap