Integrated AC type LED lamp filament

An LED filament, integrated die technology, applied in lighting and heating equipment, electrical components, circuits, etc., can solve problems such as application scope and convenience limitations, and achieve simplified process and design, good white light effect, economical and efficient communication lighting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

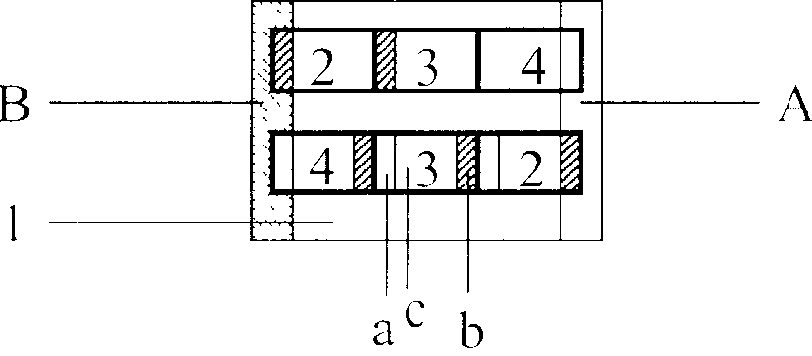

[0025] Embodiment 2, a three-stage integrated AC LED filament with a constant current source circuit, combined with figure 1 , Figure 4 with Figure 5 , compared with Embodiment 1, the constant current source circuit Ic integrated in series with each row of series integrated dies is added, and its equivalent circuit diagram is as follows Figure 4 shown. The constant current source circuit Ic has Figure 5 The structure shown includes a triode T used as a drive current regulating tube, its emitter is connected in series with a current-limiting feedback resistor Re, and its base is connected in series with a diode D2, which is then connected in parallel as a current output terminal, and its collector is connected in series with another diode D1 Afterwards, a base bias resistor Rb is connected in series with the base and then connected in parallel as the current input terminal.

[0026] In this example, the diode D1 can be an external diode or a single die in the series int...

Embodiment 3

[0027] Embodiment 3. A white light three-stage integrated AC LED filament has the same structure as Embodiment 1, and the three light-emitting diode dies 2, 3, and 4 integrated in series are red, green, and blue respectively. color.

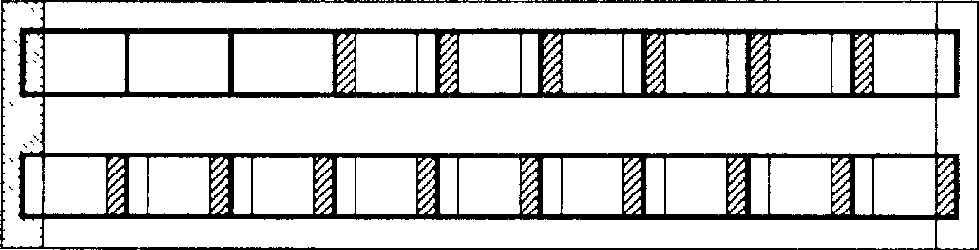

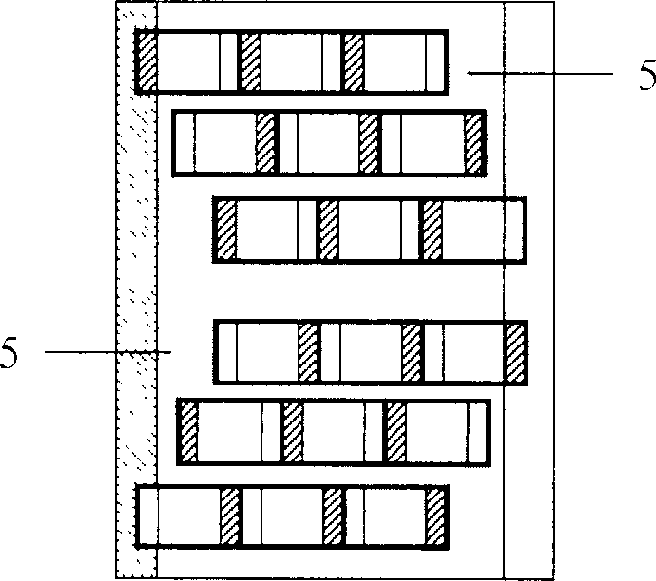

[0028] The realization of the present invention can be arranged after the single LED tube core is produced, and the required several single LED tube cores are integrated together in a multi-stage series structure to manufacture an equivalent LED with a higher VF Integrated tube core; the process can also be advanced to the production process of the single LED tube core, for example, for a single type of LED or for LEDs using the same semiconductor basic material, the realization of the present invention can be achieved in the early stage processes such as doping and masking. On the substrate material, a continuous PN junction structure is formed by direct masking, so that the subsequent process and cost can be simplified. Image 6 It is a schema...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com