Preparation method of load type silicotungstic acid catalyst and its use in preparing tetrahydrofurane

A technology of silicotungstic acid and catalyst, applied in the direction of organic chemistry, can solve problems such as equipment corrosion, liquid acid catalyst and product separation difficulties, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

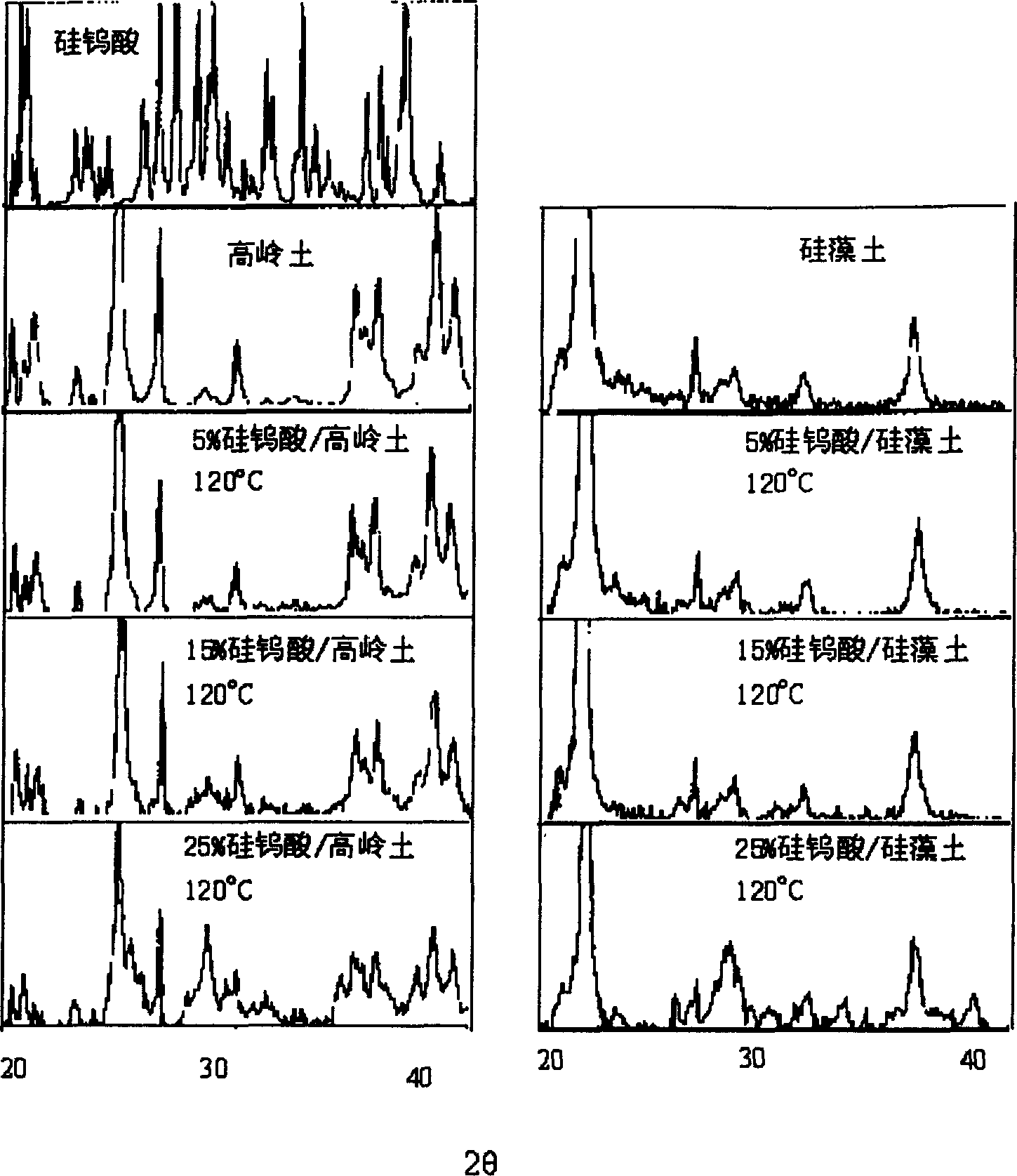

[0012] Preparation and catalytic activity test of kaolin-supported catalyst containing 5% silicotungstic acid:

[0013] Dissolve 0.5g of silicotungstic acid in 3.6ml of distilled water, and then impregnate it in 9.5g of kaolin. The pore volume of kaolin is equal to the volume of the solution of silicotungstic acid, and the mass percentage of silicotungstic acid in the catalyst is 5%. , kaolin-loaded silicotungstic acid was roasted at 120°C for 2 hours, and stirred every 20 minutes during the roasting process to prepare a kaolin-loaded catalyst containing 5% silicotungstic acid.

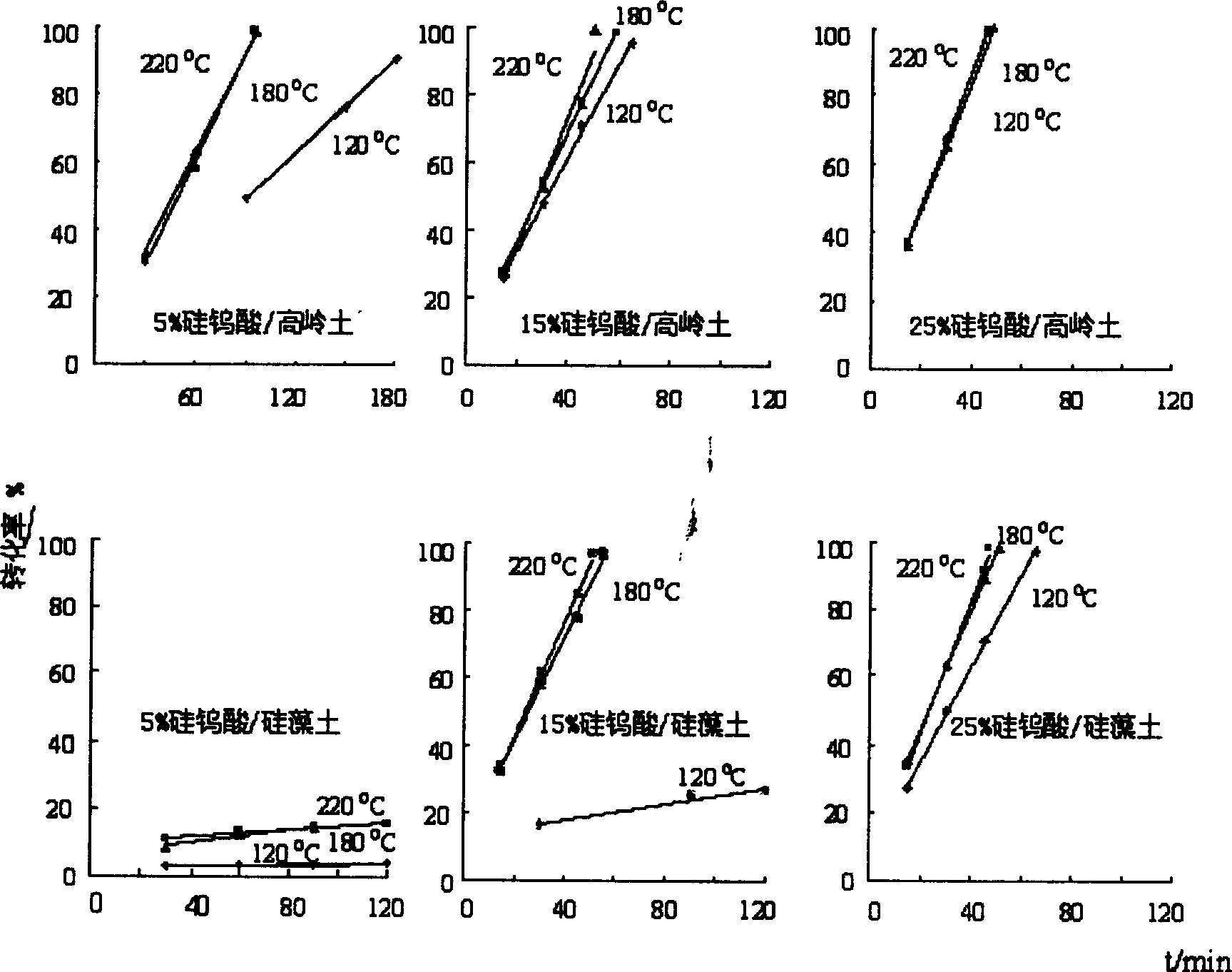

[0014] Catalyst activity test method: take 150 ml of 1,4-butanediol and heat it to 230 ° C and add 0.5 g of catalyst to react, and use gas chromatography to analyze the rectified product and the reactant in the reactor as the reaction progresses. The 1,4-butanediol and THF concentrations were used to calculate the conversion and selectivity. Such as figure 1 As shown, the conversion and selectivity ...

Embodiment 2

[0016] Preparation and catalytic activity test of kaolin-supported catalyst containing 15% silicotungstic acid:

[0017] Dissolve 1.5g of silicotungstic acid in 3.22ml of distilled water, and then soak it in 8.5g of kaolin. The pore volume of kaolin is equal to the volume of the solution of silicotungstic acid, and the mass percentage of silicotungstic acid in the catalyst is 15%. , kaolin-loaded silicotungstic acid was roasted at 180°C for 4 hours, and stirred every 30 minutes during the roasting process to prepare a kaolin-loaded catalyst containing 15% silicotungstic acid.

[0018] Catalyst activity test method: take 150 ml of 1,4-butanediol and heat it to 230 ° C and add 0.5 g of catalyst to react, and use gas chromatography to analyze the rectified product and the reactant in the reactor as the reaction progresses. The 1,4-butanediol and THF concentrations were used to calculate the conversion and selectivity. Such as figure 1 As shown, the reaction time of kaolin conta...

Embodiment 3

[0021] Preparation and catalytic activity test of diatomite-supported catalyst containing 25% silicotungstic acid:

[0022] Dissolve 2.5g of silicotungstic acid in 5.28ml of distilled water, and then immerse in 7.5g of diatomite. The pore volume of diatomite is equal to the volume of the solution of silicotungstic acid, and the mass of silicotungstic acid in the catalyst is 100%. content of 25%, silicotungstic acid supported by diatomaceous earth was roasted at 220°C for 6 hours, and stirred every 40 minutes during the roasting process to prepare 25% silicotungstic acid supported by diatomite.

[0023] Catalyst activity test method: take 150 ml of 1,4-butanediol and heat it to 230 ° C and add 0.5 g of catalyst to react, and use gas chromatography to analyze the rectified product and the reactant in the reactor as the reaction progresses. The 1,4-butanediol and THF concentrations were used to calculate the conversion and selectivity. Such as figure 1 As shown, the reaction ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com