Method for manufacturing tartary buckwheat tea

A technology of tartary buckwheat tea and tartary buckwheat is applied in food preparation, medical raw materials derived from angiosperm submen, food science, etc., and can solve the problems of not being drank and eaten very much.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] (production of tartary buckwheat tea)

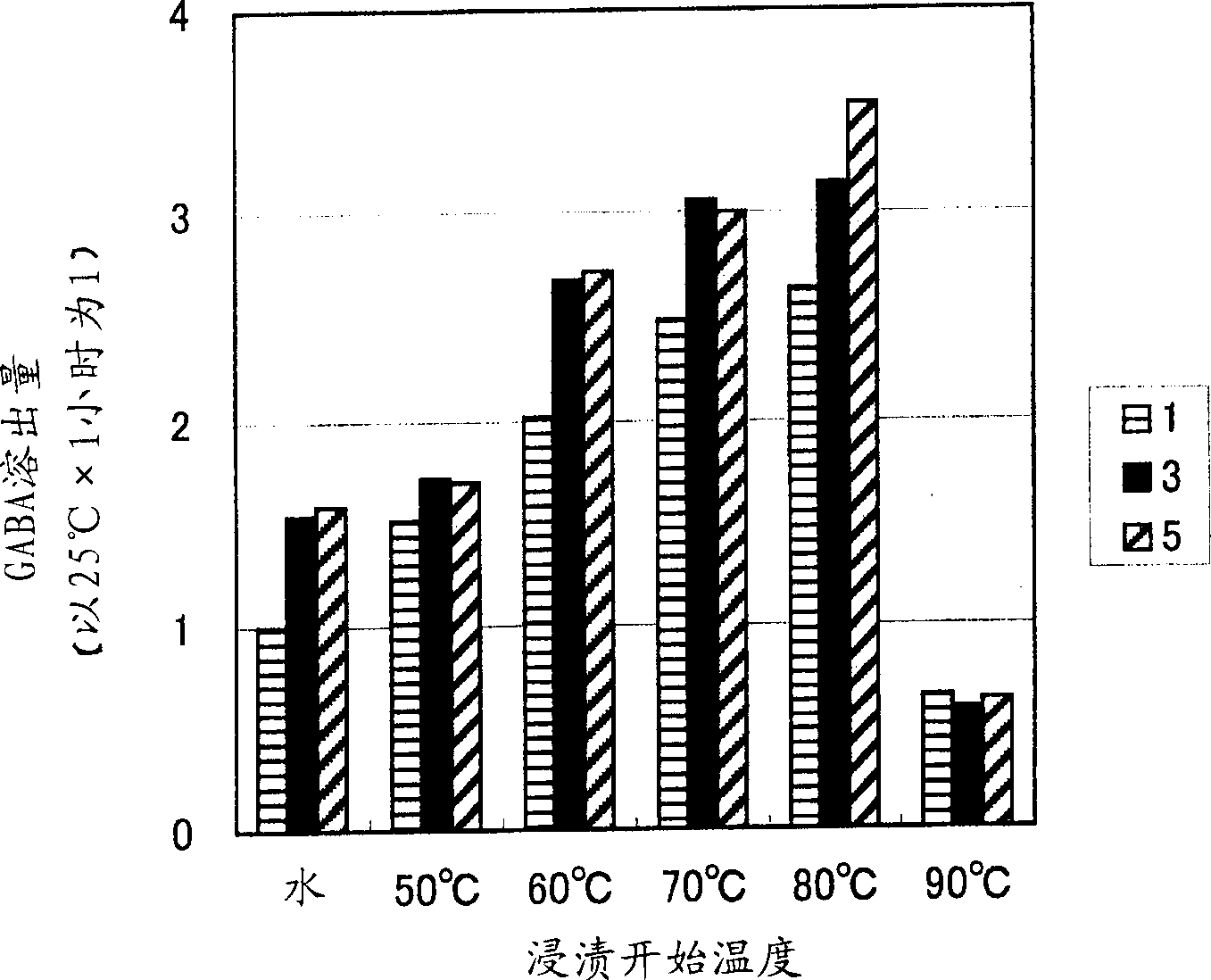

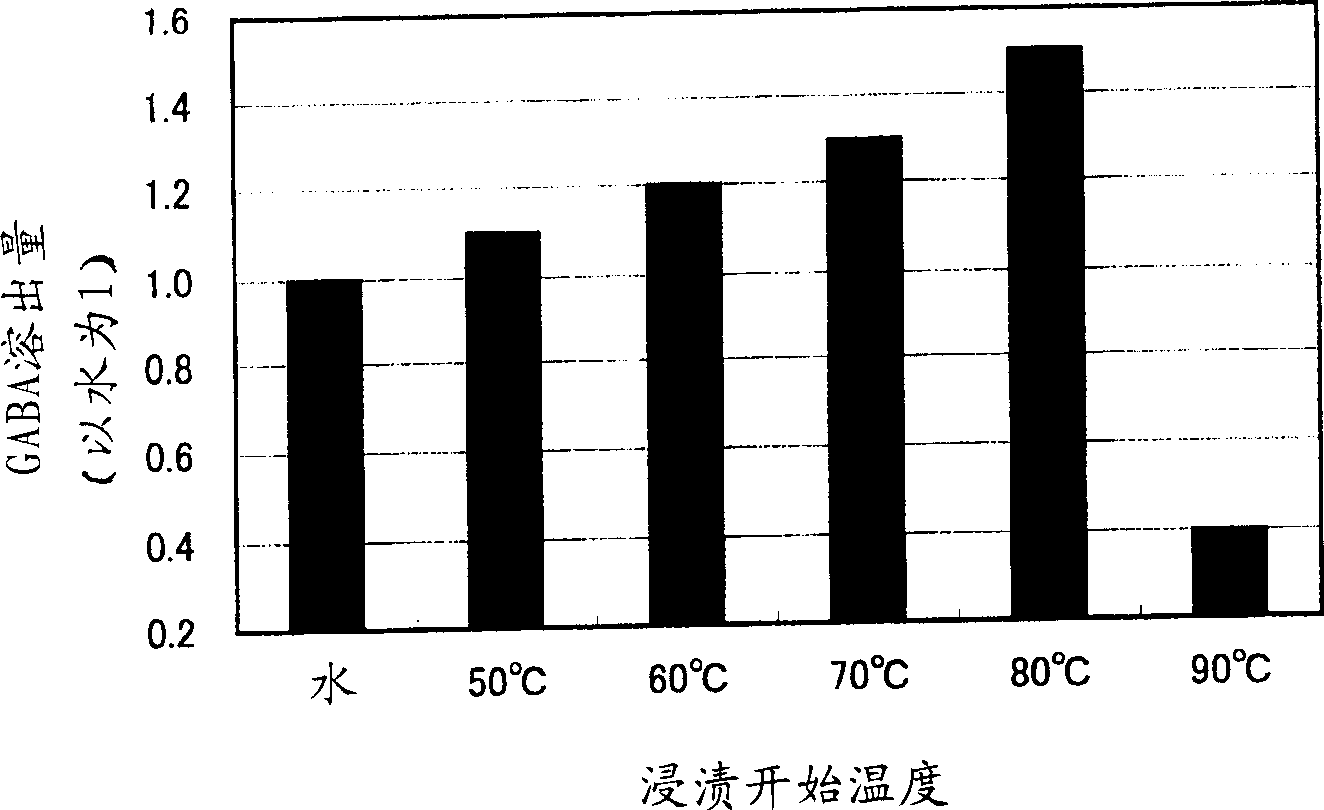

[0037] Take 1 kg of tartary buckwheat tea (grains) without husks, put it into 1500 mL of water or hot water at various temperatures adjusted to an initial temperature of 25 to 90 ° C, and store it at room temperature for 1 hour, 3 hours, or 5 hours. Impregnation (refer to Table 1). Here, the water temperature of the water described in the figure is 25°C.

[0038]After dipping, the grains of the tartary buckwheat were transferred to a steamer, and steamed for 25 minutes while stirring every 5 minutes (see Table 1). Then, it was dried at a predetermined temperature for a predetermined time using a hot air dryer (see Table 1). At this time, the water content of the dried grains was 10%.

[0039] Next, after the dried grains are peeled with a wheat grinder, the kernels and shells are separated by a rotary sieve (No. 10, No. 30) and a wind screener, and a part of the kernels are obtained as dried tartary buckwheat tea. .

[0040] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com