Optical type appearance testing method and optical type appearance testing device

An appearance inspection device and appearance inspection technology are applied in the fields of optics, measuring devices, and material analysis through optical means, which can solve problems such as the influence of inspection results, and achieve the effect of reducing false inspections and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

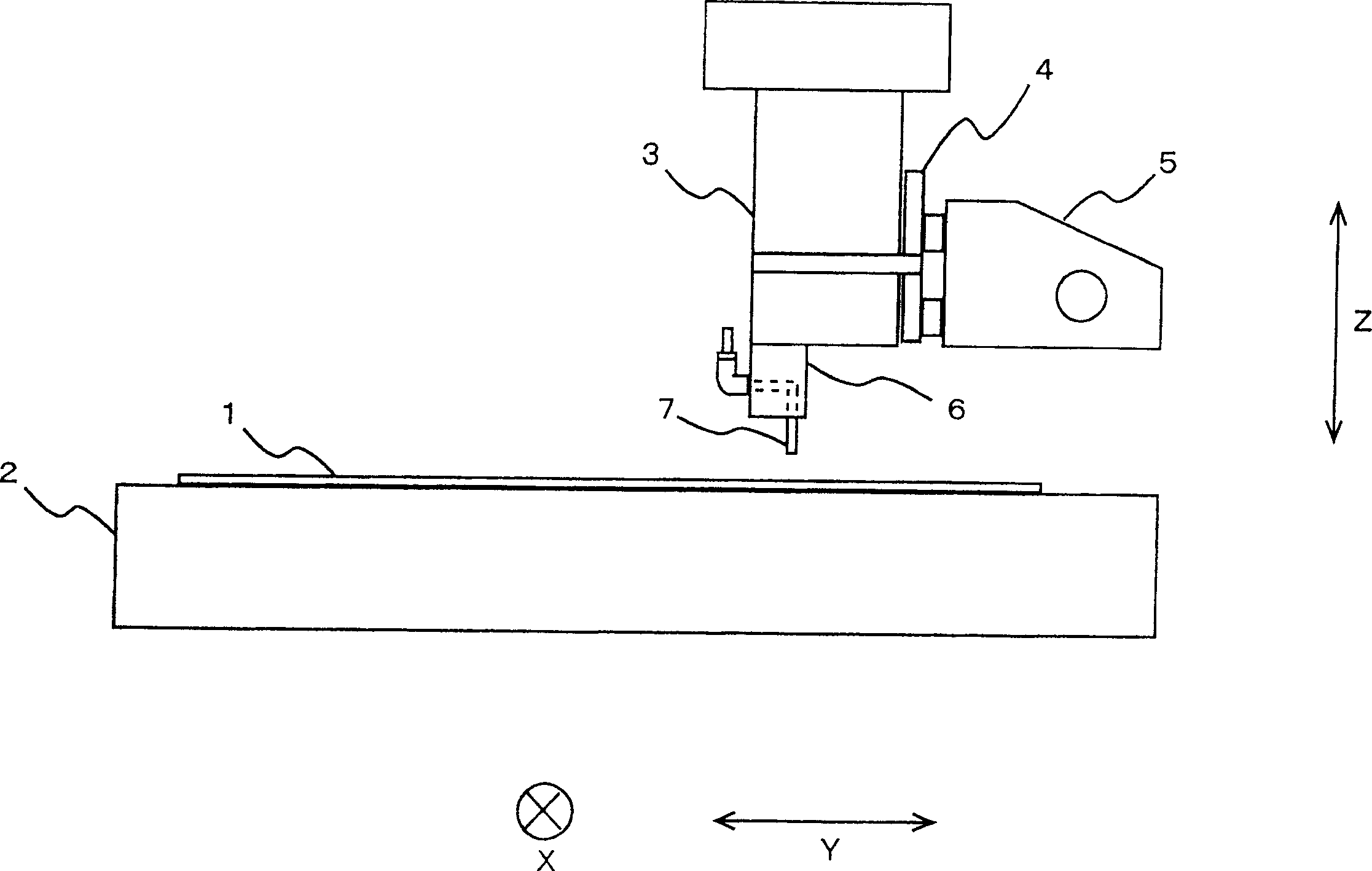

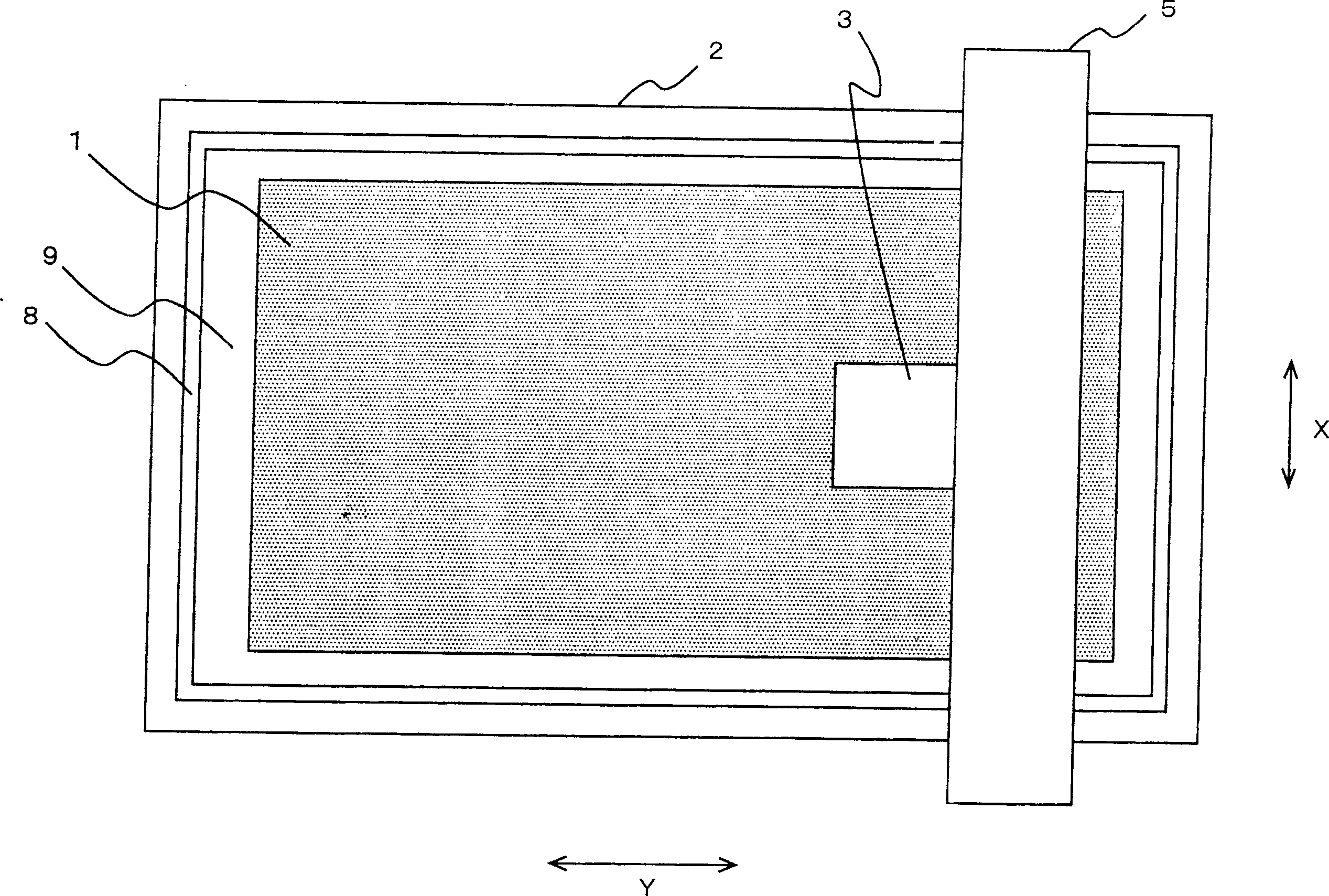

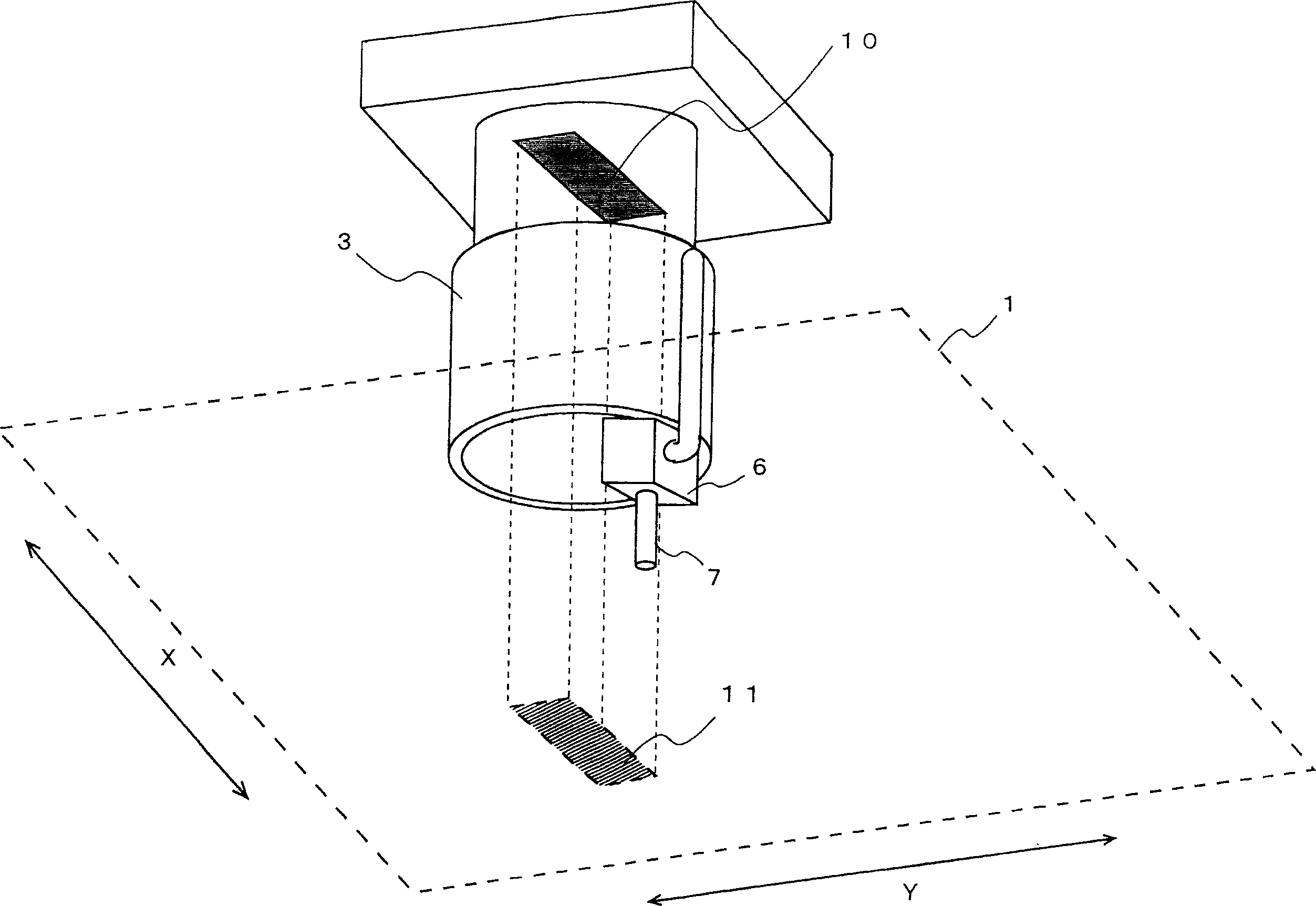

[0032]Embodiments of the present invention will be described below with reference to the drawings. Here, in order to make the description concrete, a case where a film mask on which a wiring pattern is formed is inspected will be described as an example. This example is not intended to limit the present invention. That is, the present invention is not limited to the inspection of thin film masks, but is also effective for inspection of flexible thin plate substrates.

[0033] figure 1 It is a side view schematically showing the overall configuration of an optical visual inspection device according to an embodiment of the present invention. figure 2 is viewed from above the device figure 1 floor plan of the structure. figure 1 with figure 2 Among them, the optical appearance inspection device is composed of a stage 2 , an imaging unit 3 , a Z-axis base 4 , an X-axis base 5 , an air ejection member 6 , and a nozzle 7 .

[0034] figure 2 Among them, the stage 2 is forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com