Improved sublevel caving method without bottom column

A segmented caving method without pillars, which is applied in ground mining, earth drilling, underground mining, etc., can solve the problems of increasing mine construction investment intensity, large ore dilution, and low mining intensity, so as to eliminate blasting Partition wall accident, increase the amount of ore mined, and improve the effect of ore recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

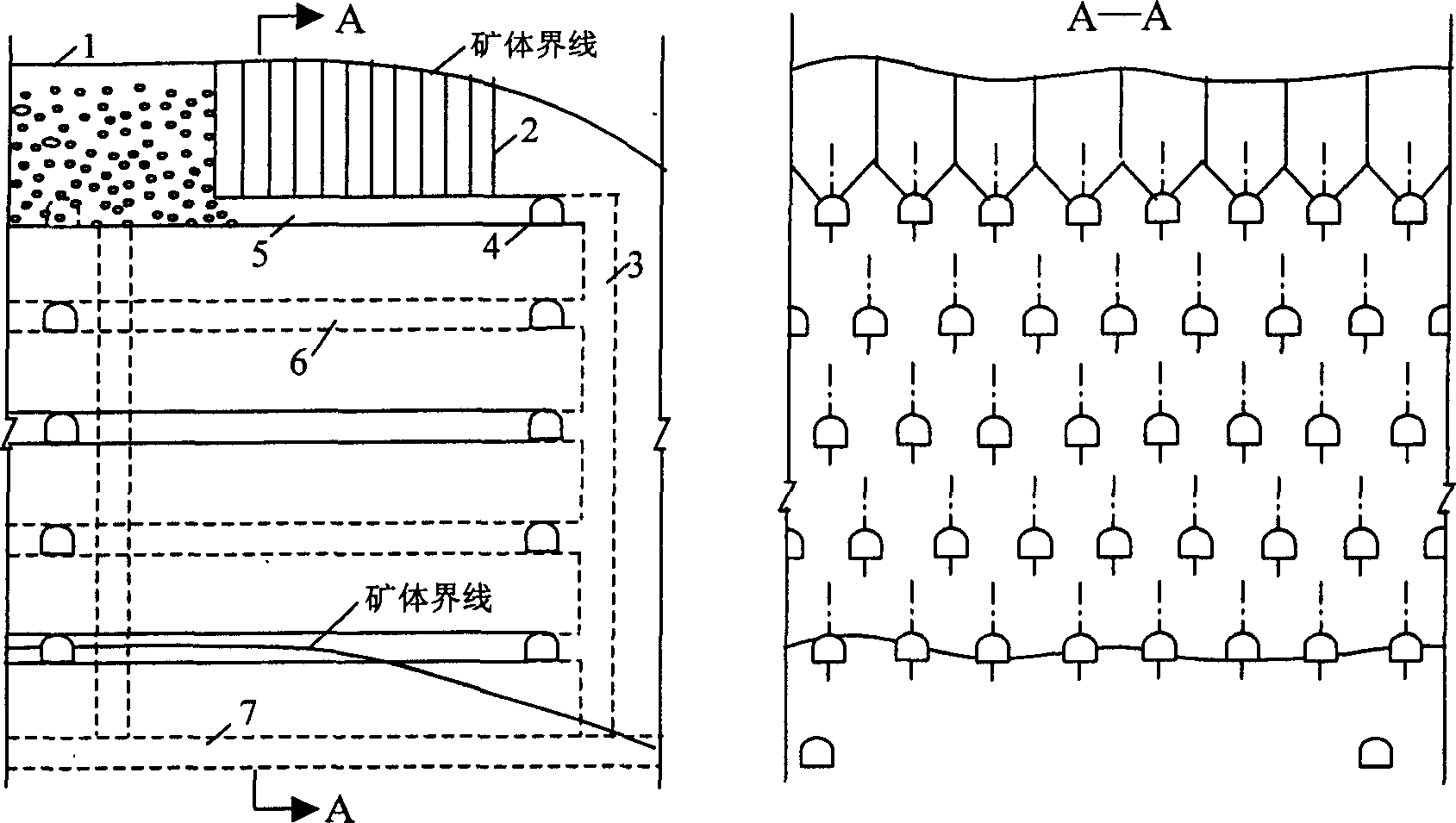

[0042] An iron mine in Handan City, Hebei Province, most of the ore structure is loose and broken, easy to fall, suitable for use figure 2 The stope structure, the present invention draws up the following mining scheme for this reason:

[0043] Taking the middle section of -50 meters of the mine as the middle section of the first mining, the height of the induced caving area is designed to be 28-45m, and the distance between the routes is 18m; The area height is 15m, and the approach distance is 9m. Use QZG80A type medium and high wind pressure down-the-hole drilling rig to drill rock, 4.0m 3 Electric shovel out of the mine, the access section height × width is 3.5 × 4.2m 2 .

[0044] After implementing the present invention, the mining heap coefficient of the main mining area is reduced from the original 3.6m / KT to 2.07m / KT, the production efficiency is 60,000 tons / month, the ore recovery rate reaches 92.5%, and the ore dilution rate is 11%. about. In the case of comple...

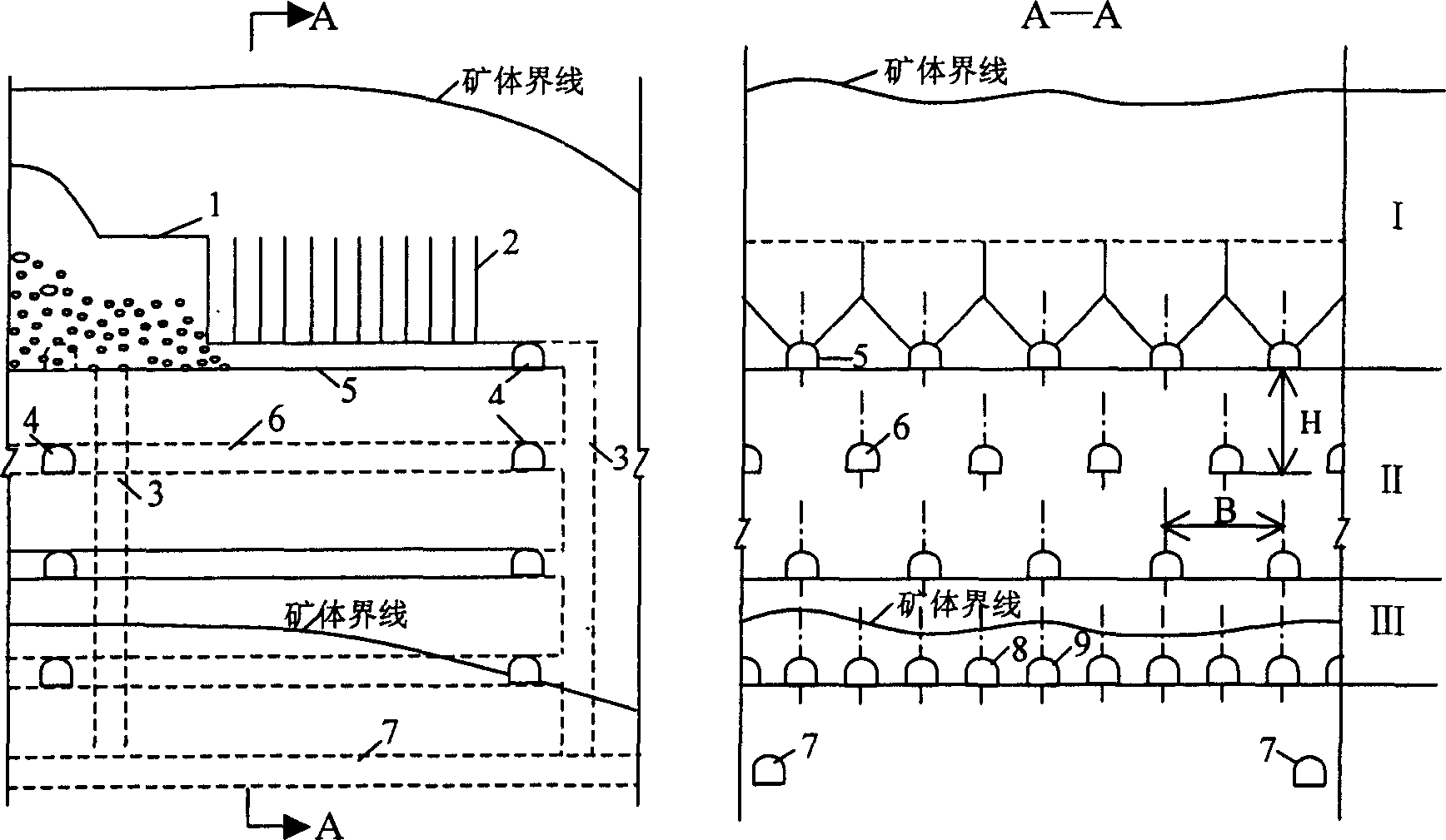

Embodiment 2

[0046] A medium-thick ore body in the west of an iron mine in Hebei Province, the ore is unstable to moderately stable, and the mining ground pressure is large. Since the ore is easy to fall and the size of the fall is small, only the induced fall area and the bottom recovery area are set up. The overall design scheme is as follows Figure 6 shown. The height of the induced caving area is designed to be 10-25m, and the approach distance is 16m; the height of the recovery area at the bottom is 10m, and the joint layout of the dense approach and the recovery approach is adopted, and the approach distance is 8-16m; the rock cutting height of the recovery approach (calculated from the roadway roof) is 2 ~ 5m. Adopt QZG80A medium and high wind pressure down-the-hole drilling rig for rock drilling, bucket capacity 4.0m 3 Electric shovel out of the mine, the access section height × width is 3.5 × 4.2m 2 . Experimental research shows that the ore recovery rate is about 85%, and th...

Embodiment 3

[0048] The scheme drawn up for an iron mine in Anshan Iron and Steel Co., Ltd. to convert from open pit to underground mining. The ore body of this mine is thick and large, the dip angle is steep, the Platinum hardness coefficient f=12-14, and the fault structure of the ore deposit is developed, which is suitable for mining Figure 7 Mining plan.

[0049] A technical scheme has been designed to transform from deep concave open-pit mining to simultaneous open-pit and underground mining, and then transition to underground high-efficiency mining. Underground mining adopts imported high-power rock drilling and mining equipment. Figure 7 In the stope structure shown, the height of the induced caving area is 50-120m, and the approach spacing is 20-25m; the section height of the normal mining area is 20-30m, and the approach spacing is 20-25m; the bottom recovery area adopts dense access Form whose height is the height of one segment. For the sake of safety, at least one monitorin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com