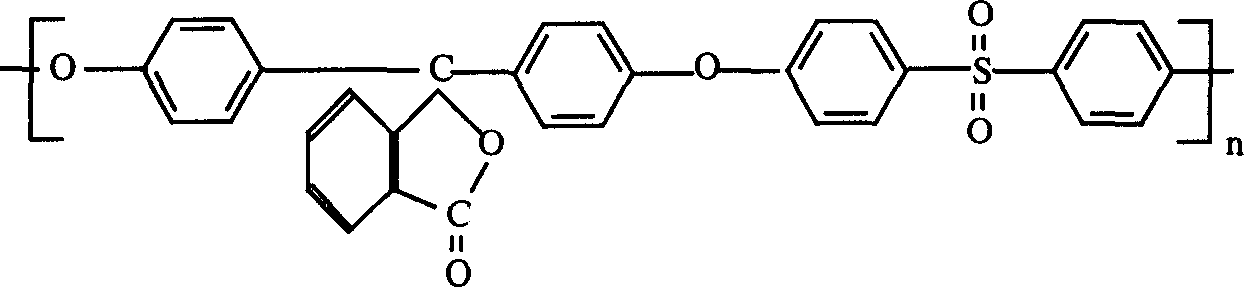

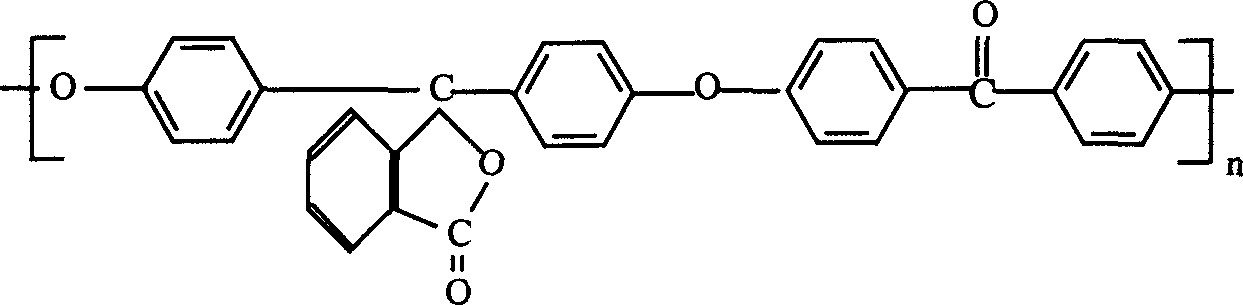

Ultrafiltration membrane of hollow fiber made form polyarylether sulfone or polyarylether ketone of containing phenolphthalein lateral group, and preparation method

A technology of polyaryl ether sulfone and polyaryl ether ketone, which is applied in the field of hollow fiber ultrafiltration membrane separation and membrane separation, can solve the problems of high temperature sterilization of membrane and limit the application of membrane, and achieve good anti-oxidation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Example 1: Take 70g of the membrane material polyarylethersulfone (P), 100g of the solvent DMAc (S1) and 230g of NMP (S2) to form a mixed solvent, add 25g of propionic acid (A), and prepare 425g of membrane solution. Stir at 90°C for 15 hours to prepare a uniform film-forming solution. After filtering and defoaming, the hollow fiber membrane is prepared according to the preparation method "6" of the present invention. The pressure of the spinning kettle is 0.1MPa, the temperature of the spinning stock solution (kettle temperature) is 30°C, the drawing speed is 25m / min, the core liquid is water at 60°C, the air gap is 0, the first gel bath is water, and the temperature is 60°C. The second gel bath was water at 60°C.

[0080] After soaking in water at 25°C for 24 hours, the performance of the membrane was tested. Under the conditions of operating pressure of 0.1MPa and temperature of 25°C, the pure water flux of the membrane is 735L / m 2 .h, the rejection rate of the me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com