Automated equipment for adding reinforced granules in use for spraying depostion

A technology for enhancing particles and spray deposition, applied in spray devices, liquid spray devices, etc., can solve the problems of uneven particle addition, uneven distribution, poor repeatability, etc., and achieve the effect of simple structure, convenient use and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

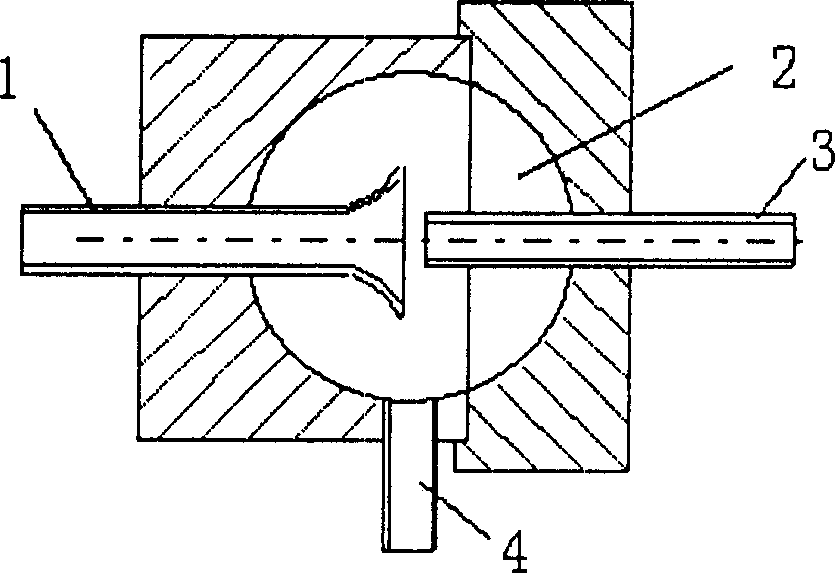

[0013] Referring to the accompanying drawings, the spherical cavity 2 is connected with the inlet pipe 3 and the outlet pipe 2 on the same axis, the ratio of the diameter of the inlet pipe 3 to the diameter of the outlet pipe 1 is 1:1.3, and there is a gap of 1 mm between the inlet pipe 3 and the outlet pipe 1 , The spherical cavity 2 is also provided with a feeding tube 4 .

Embodiment 2

[0015] Referring to the accompanying drawings, the elliptical cavity 2 is connected with the inlet pipe 3 and the outlet pipe 1 on the same axis, the ratio of the diameter of the inlet pipe 3 to the diameter of the outlet pipe 1 is 1:3, and there is 2mm between the inlet pipe 3 and the outlet pipe 1 The gap, the elliptical cavity is also provided with a delivery pipe 4.

[0016] When the present invention is in use, the inlet pipe 3 is connected with high-pressure gas with a pressure ranging from 1.5MPa to 5MPa, the outlet pipe 1 is connected with an atomizing nozzle, and the end of the feeding pipe 4 is directly inserted into the reinforced particles. The working principle is to use a certain air pressure The conveying gas enters the cavity 2 from the inlet pipe 3. When the conveying gas of a certain pressure passes through the cavity 2 quickly, a negative pressure will be formed in the cavity 2, so that the reinforced particles will automatically flow from the conveying pipe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com