Filtering speed reducer

A deceleration mechanism and eccentric technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of easy fatigue damage, small power transmission of planetary reducer, thin wall and easy damage, etc., and achieve relatively small size and large deceleration ratio, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

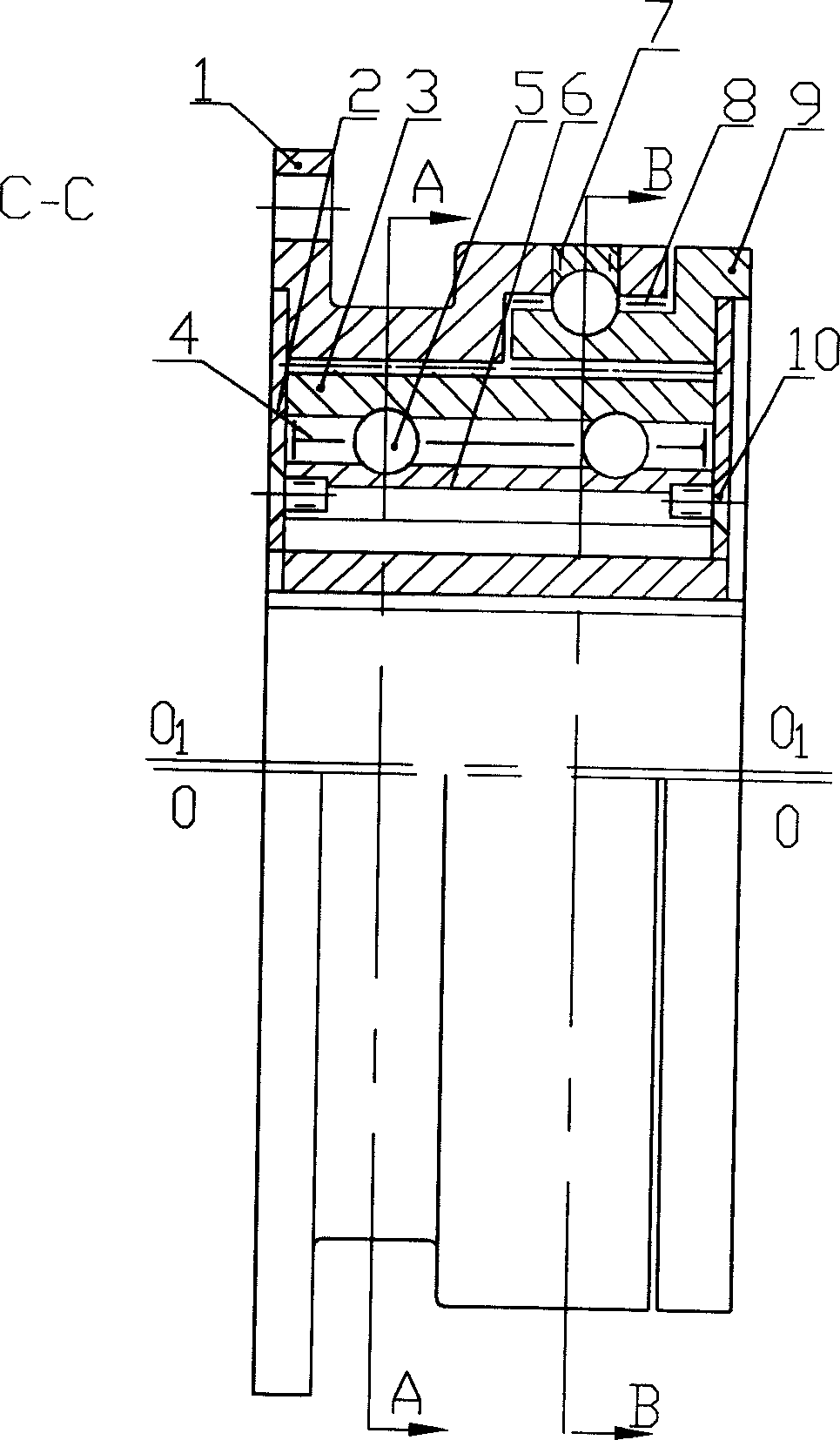

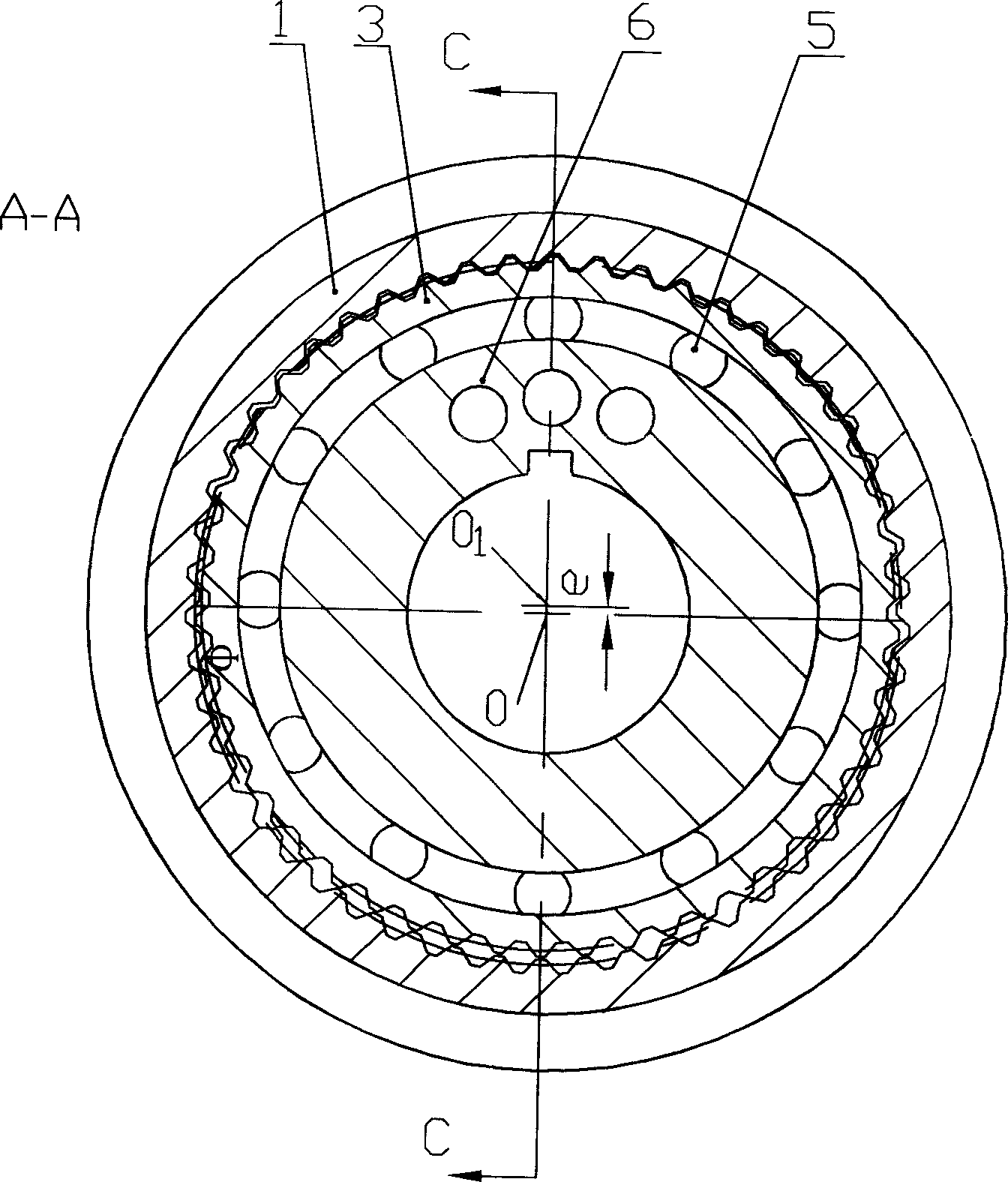

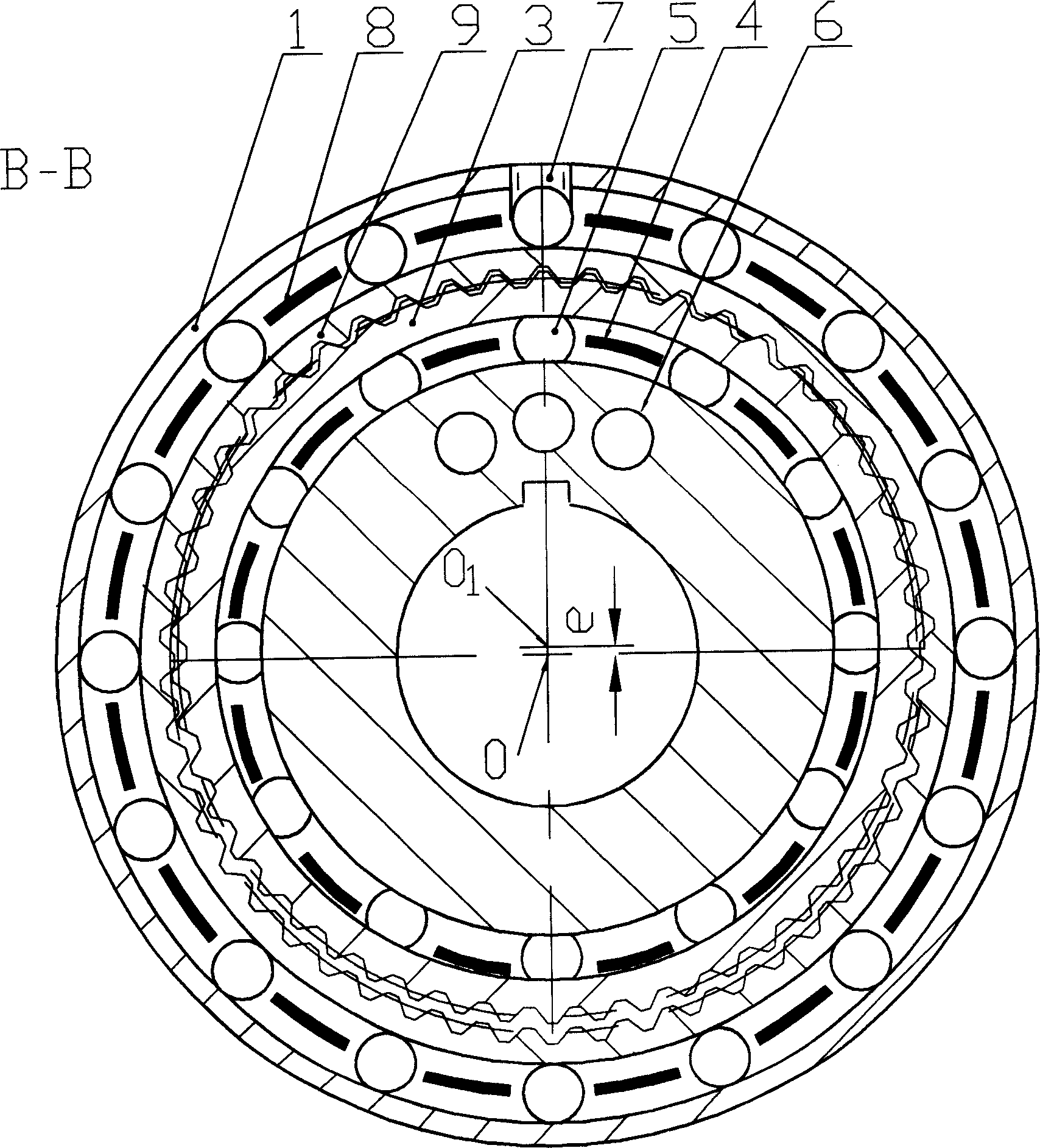

[0011] The filtering speed reducer involved in the present invention is fixed on the machine body or the motor by the flange plate on the internal gear 1 through screws, so the internal gear 1 remains motionless. The shaft of the motor drives the eccentric wheel 6 to rotate at a high speed through the flat key. Output low-speed rotation by output internal gear 9. The filter reducer is composed of an eccentric reduction mechanism, a filter spline mechanism and a three-way thrust bearing. Eccentric reduction mechanism such as figure 1 A-A section in and figure 2 As shown, it is composed of eccentric wheel 6, rolling bearing, cylindrical gear 3 and internal gear 1. The outer circle of the eccentric wheel doubles as the inner ring surface of the rolling bearing. Therefore, the outer raceway of the eccentric wheel is distributed on the eccentric, and its arc c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com