Process for making voltage transformer enamel-covered lenticular wires

An enameled flat wire, production process technology, used in coil manufacturing, flat/ribbon cables, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1, the production of enameled rectangular wires for transformers by one-step extrusion molding process

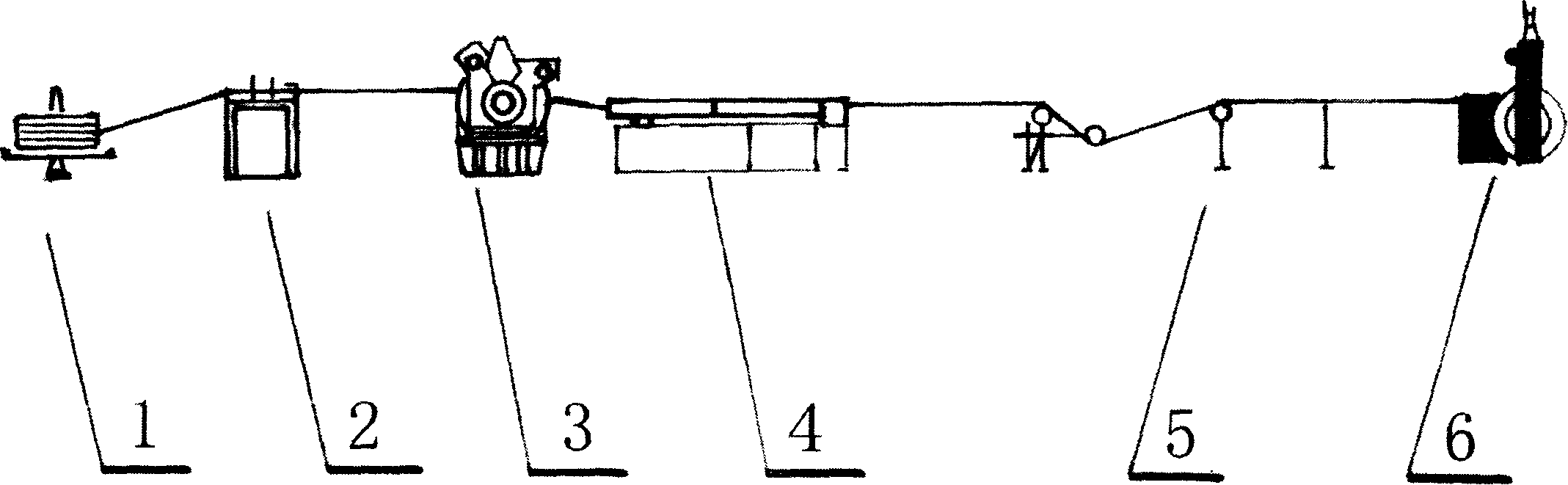

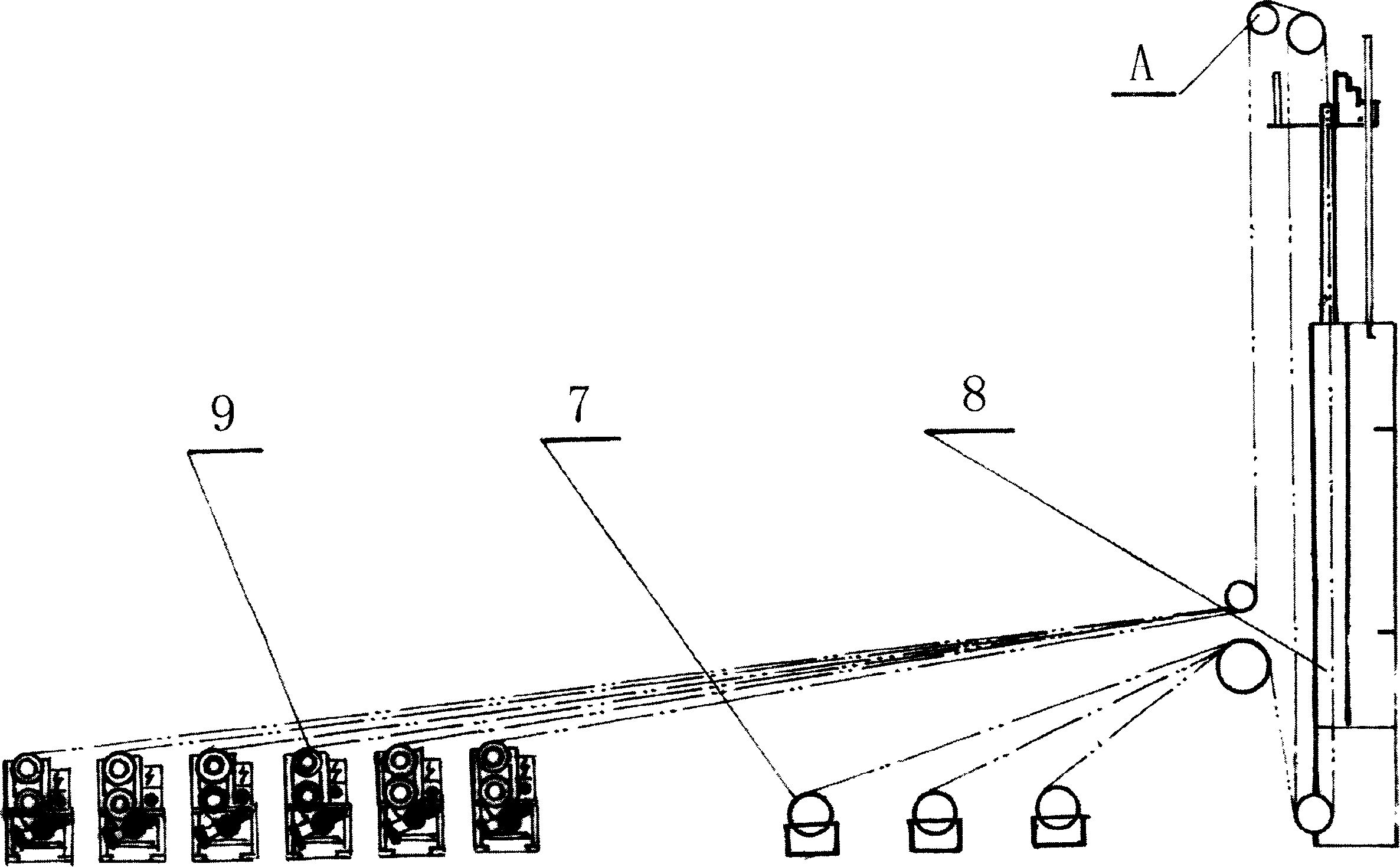

[0044] The transformer enameled rectangular wire is produced by the extrusion one-step molding process of the present invention, and the copper rod is used as the raw material to produce the enameled rectangular wire through extrusion molding, painting and finished wire winding. The extrusion molding production process is partially driven by extrusion The one-time extrusion molding process composed of continuous extrusion unit consisting of feeding, wheel groove friction extrusion and heating, and extrusion molding through die holes replaces the traditional cold-drawn wire drawing process. Extrusion one-time forming continuous extrusion unit model TLJ300, produced enameled rectangular wire specification QZYB-2 / 180 2×11.8mm, size deviation 2 +0.02 / -0.01mm , 11.8 +0.05 / -0.02mm , The production tonnage is 18 tons. The overall production process includes: copper rod ...

Embodiment 2

[0066] Example 2, the use of one-step extrusion molding process to produce transformer enameled rectangular wire

[0067] The transformer enameled rectangular wire is produced by the extrusion one-step forming process of the present invention, and the production takes copper rods as raw materials. Extrusion one-time forming continuous extrusion unit model TLJ250, the produced enameled flat wire specification QQB-1 / 120 2.50×5.30mm, size deviation 2.50 ±0.02mm , 5.30 ±0.04mm , The production tonnage is 35 tons. The overall production process includes: copper rod conveying and straightening-one-time extrusion molding and cooling and oxidation prevention-soft bare wire take-up-painting and baking line-painting and baking operation-finished product take-up.

[0068] The main process equipment is the same as in Example 1 except that the one-time forming continuous extrusion unit is TLJ250.

[0069] The main process control conditions are as follows:

[0070] 1. Copper rod specification ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com