Gas diffusion electrode assembly and its production

A technology of gas diffusion electrodes and components, applied in the direction of electrolysis components, electrodes, electrolysis process, etc., can solve the problems of difficult to obtain large electrodes, low mechanical strength and deformation of gas diffusion electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

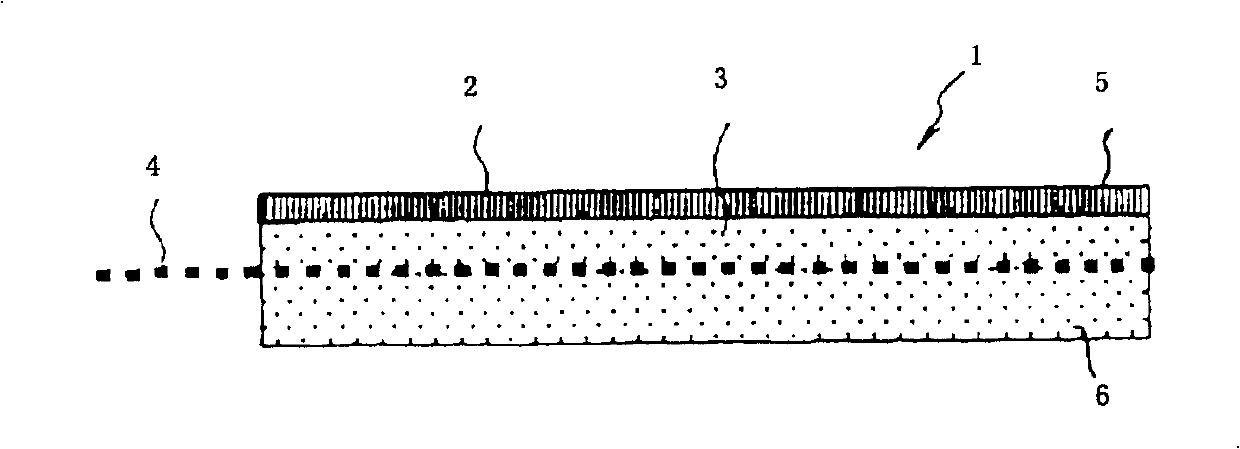

Method used

Image

Examples

Embodiment 1

[0087] In 200 parts by weight (the following parts are all expressed by weight) of 4% (weight) (the following percentages are all expressed by weight) Add 2 parts of hydrophobic carbon black (Denka Black; average particle size is Produced by Denki Kagaku Kogyo K.K.). The resulting mixture was stirred to disperse the carbon black. The carbon black dispersion was treated with an ultrasonic disperser (manufactured by BRANSON; 500 W) for 5 minutes and cooled with water to further disperse the carbon black. As a result, the particles in the dispersion were dispersed with an average particle diameter of 1.6 µm. To this dispersion liquid was added 10 parts of silver sol (test product produced by Tanaka Kikinzoku Kogyo K.K.; average particle diameter: 0.1 µm). The mixture was stirred to homogenize. Then, 1.5 parts of PTFE dispersion D-1 (average particle diameter: 0.3 µm; produced by Daikin Industries, Ltd.) was added and the mixture was stirred to make it uniform. 300 parts of...

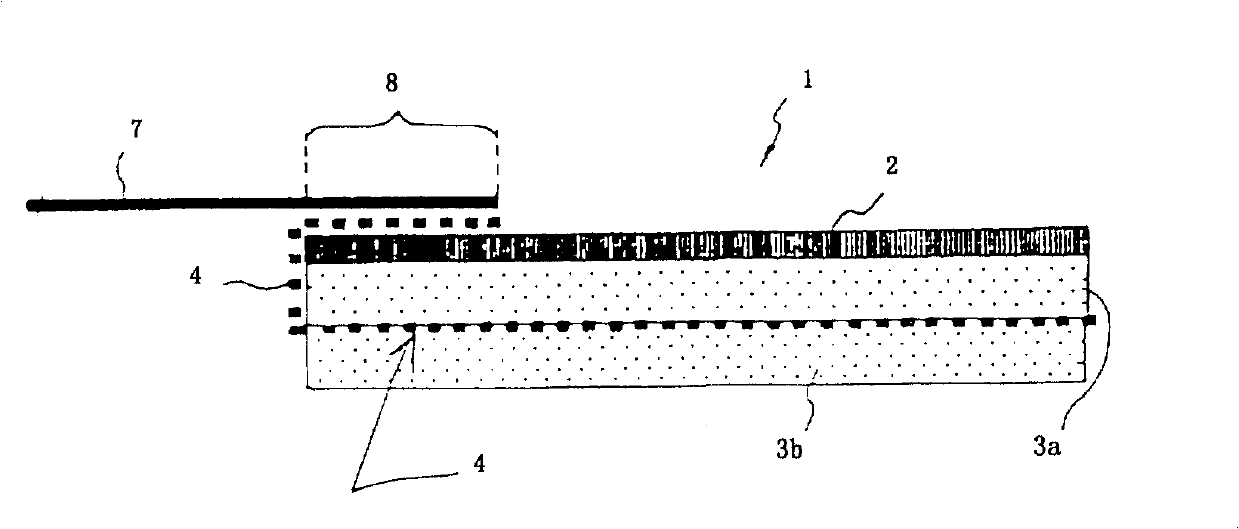

Embodiment 2

[0094] In Example 1, the gas diffusion electrode 1 was produced by hot pressing and then bonded to a silver sheet ("silver sheet" is used here as the border material). However, in the present embodiment, the silver-rimmed gas diffusion electrode assembly is obtained by combining the reaction layer / intake layer sheet, the silver wire mesh as the collection layer 4, the silver sheet, and the air inlet layer sheet 3b in a The order is stacked up, at 350°C at 50 kg / cm 2 The assembly was pressed for 60 seconds. The electrolysis of sodium chloride was performed using the electrode assembly as an oxygen cathode. As a result, at 90°C, 32% NaOH and 30A / dm 2 A cell voltage of 1.96V was obtained under the conditions.

[0095] The electrode assembly produced in this embodiment has a structure in which a border material is inserted between the air intake layer sheet 3a and the air intake layer sheet 3b.

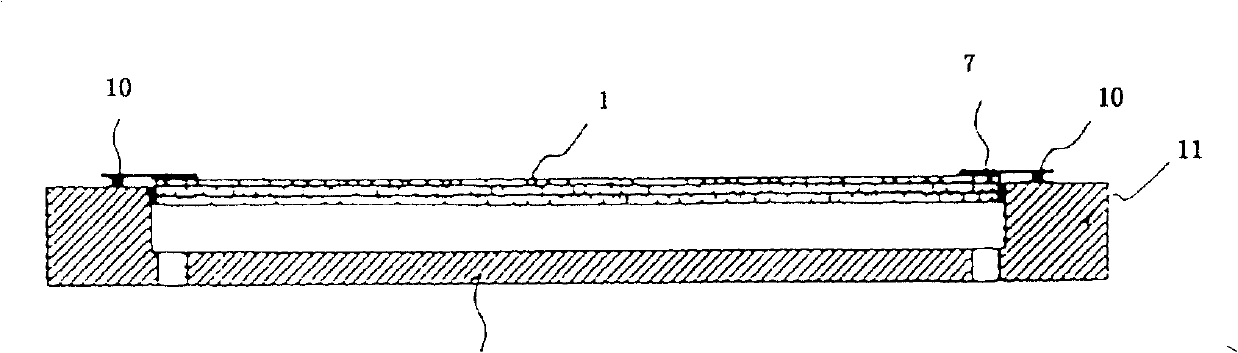

Embodiment 3

[0097] From a 0.2mm thick rectangular silver piece of 13cm x 23cm, the interior was cut out with a size of 10cm x 20cm so that the peripheral portion of the silver piece was kept in the shape of a long and narrow strip with a width of 1.5cm to produce a silver frame. A gas diffusion electrode having a size of 11.5 cm x 21.5 cm was obtained in the same manner as in Example 1, in which the peripheral portion of the silver mesh had been bent toward the reaction layer side. Fine silver particles were applied to the surface of the curved peripheral portion of the silver mesh. The silver frame obtained above was superimposed thereon. at 100 kg / cm 2 The laminated part was hot-pressed at the area pressure of 260° C. to obtain a gas diffusion electrode with a silver frame.

[0098] The electrical resistance between the silver frame and the gas-diffusion electrodes was low, about half that of a corresponding conventional assembly without intercalated fine silver particles. The peel s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com