Three-sensor style encoder

A sensor and encoder technology, applied in the field of photoelectric sensing, can solve the problems of low precision, high processing cost, poor anti-interference of the encoder, etc., and achieve the effect of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

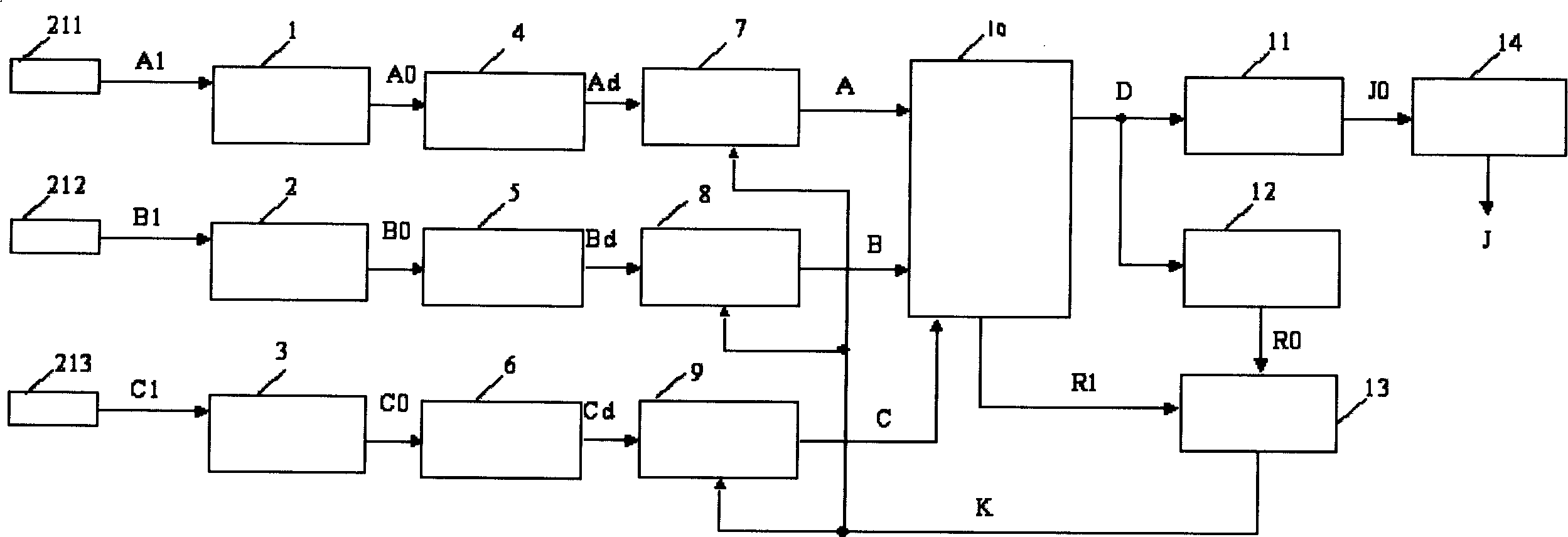

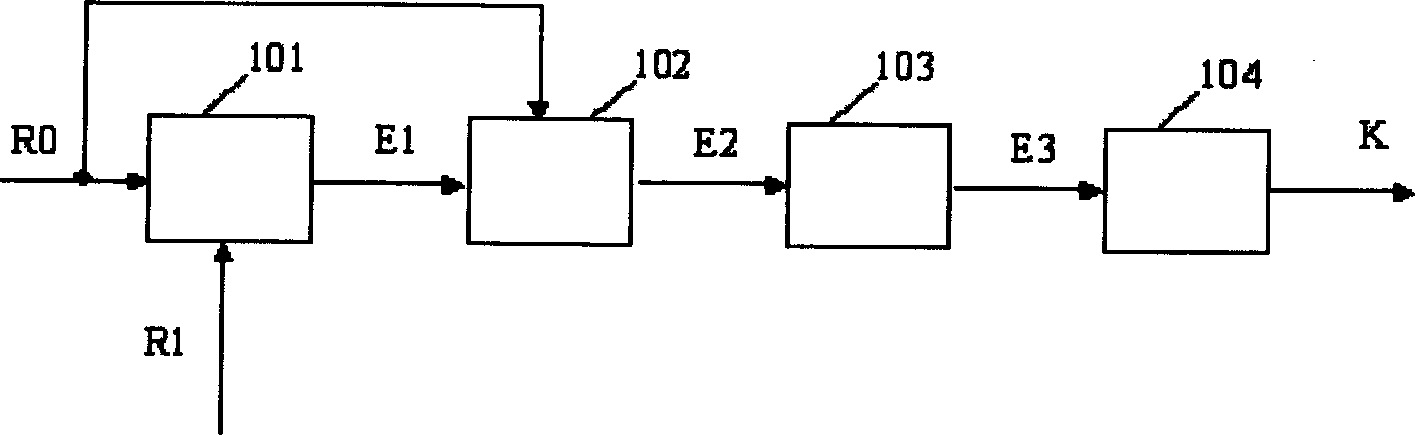

[0015] exist figure 1 In the quadrant position, three magnetic sensors are equidistantly arranged on the same circle, the angle between two adjacent sensors is 120°, and the output signal (A1) of the magnetic sensor (211) is connected to the amplifier (1) , the output signals (B1), (C1) of the other two magnetic sensors (212), (213) are respectively connected to the amplifier (2) and the amplifier (3), and the three amplifiers (1), (2), (3) The three output signals (A0), (B0), (C0) are respectively connected to the input ends of three AD converters (4), (5), (6), and the three AD converters (4), (5), Three output signals (Ad), (Bd), (Cd) of (6) are respectively connected to an input end of three multipliers (7), (8), (9), three multipliers (7), ( 8), three output signals of (9) connect the input end of synthesizer (10), the output signal (K) of coefficient corrector (13) connects another input end of three multipliers respectively, synthesizer (10) The output signal (D) of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com