Sectional-drum-shape X-ray source

An X-ray, cylindrical technology, applied in the direction of X-ray equipment, electrical components, etc., can solve the problems of difficult high-voltage insulation shielding, increased X-ray source weight, inconvenient movement and handling, and easy to achieve high-voltage insulation protection. , Reduce the difficulty of processing and achieve the effect of quality uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

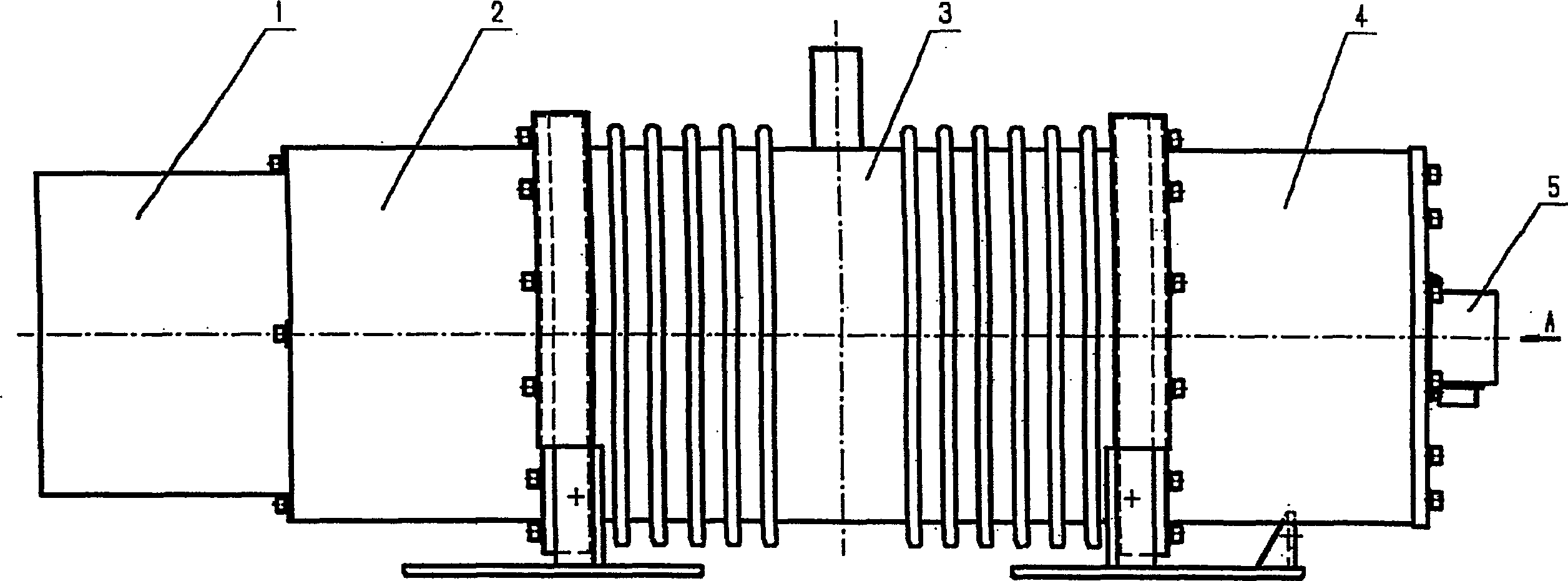

[0029] The present invention will be described in further detail below in conjunction with accompanying drawing, as figure 1 As shown, the schematic diagram of the external structure of the segmented cylindrical X-ray source is composed of five parts: the expansion part, the positive side pressure doubler sampling circuit area, the X-ray tube placement area, the negative side voltage doubler sampling circuit area, and the sealing ring.

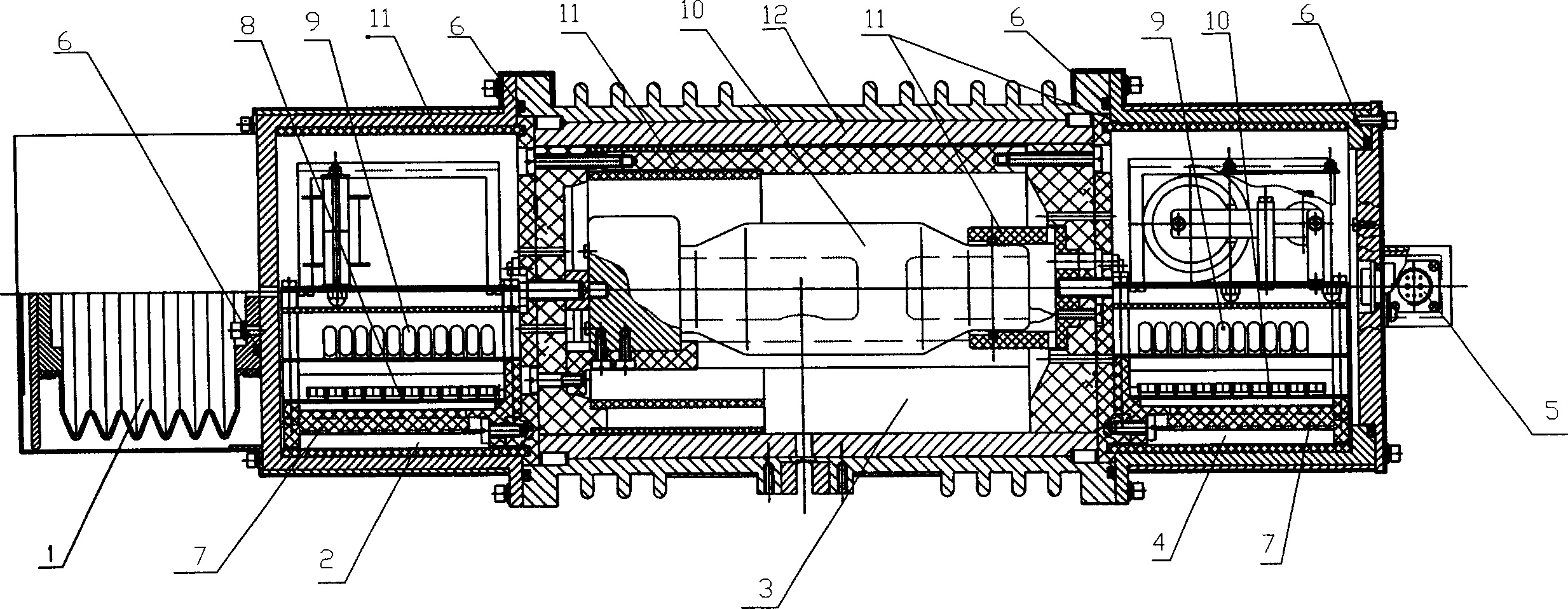

[0030] Such as figure 2 As shown, the expansion part 1 is assembled from a plurality of parts such as a sealing flange and a telescopic capsule to form a closed and telescopic volume, which is assembled in the positive pressure doubler sampling circuit area 2 through a sealing ring 6 and screws. On the end face, it can relieve the need of volume change due to thermal expansion and cold contraction of insulating oil; positive side voltage doubler sampling circuit area 2 is composed of sampling circuit board 8, voltage doubler circuit board 9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com