Method and device for controlling gear shift of mechanical transmission

A control method and control device technology, applied in control devices, engine control, electrical control, etc., can solve problems such as longer time, longer time, and uncomfortable occupants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

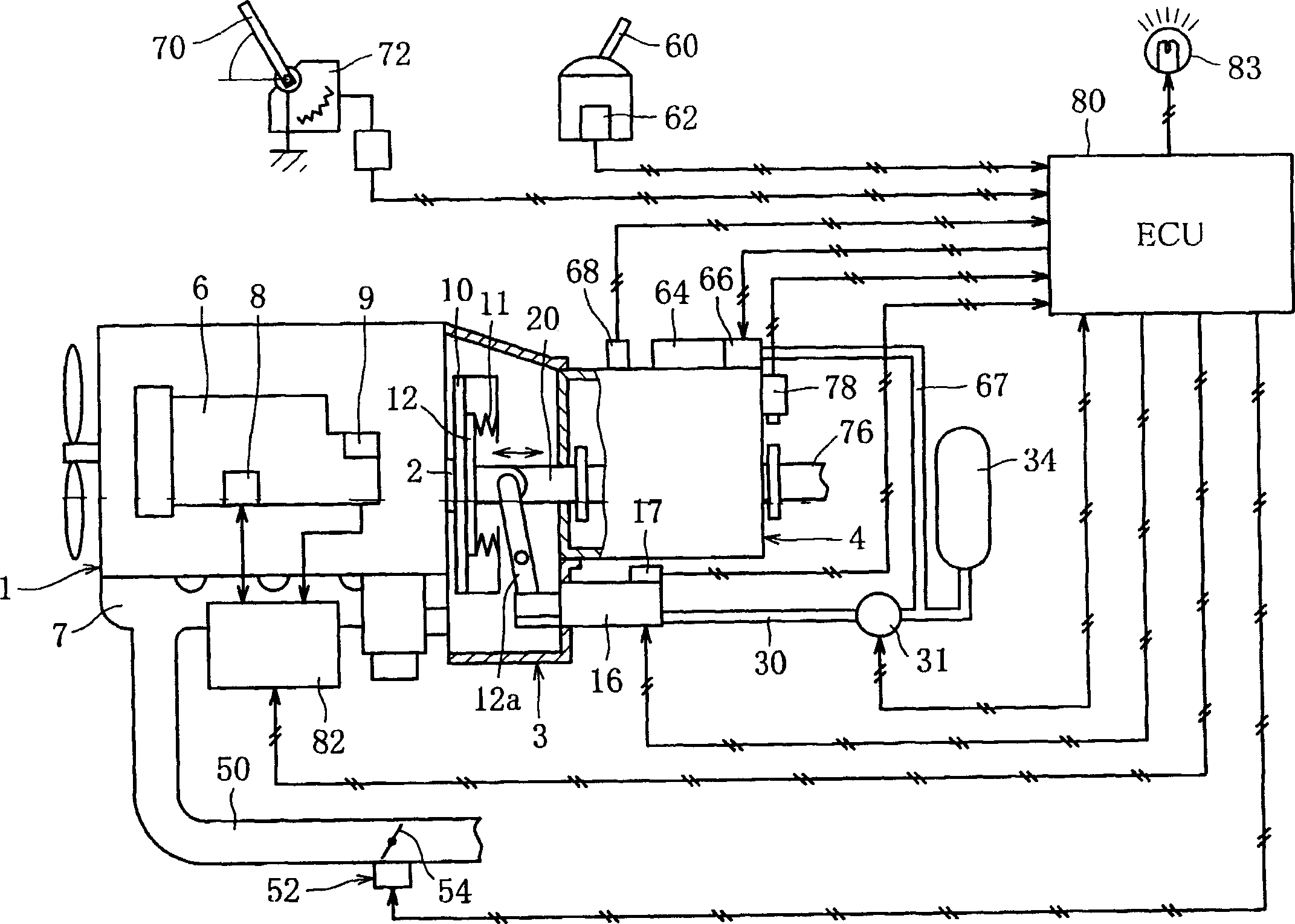

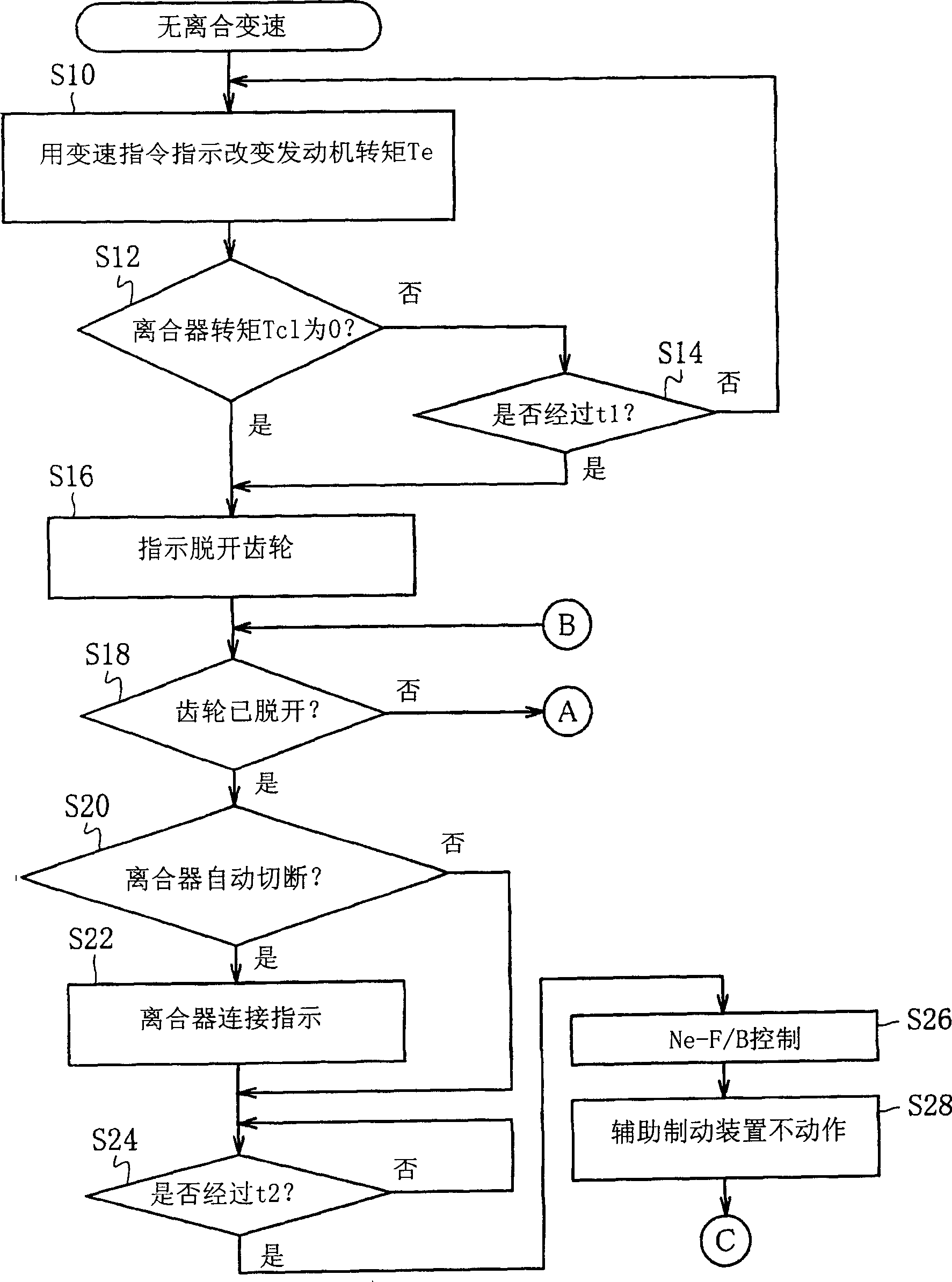

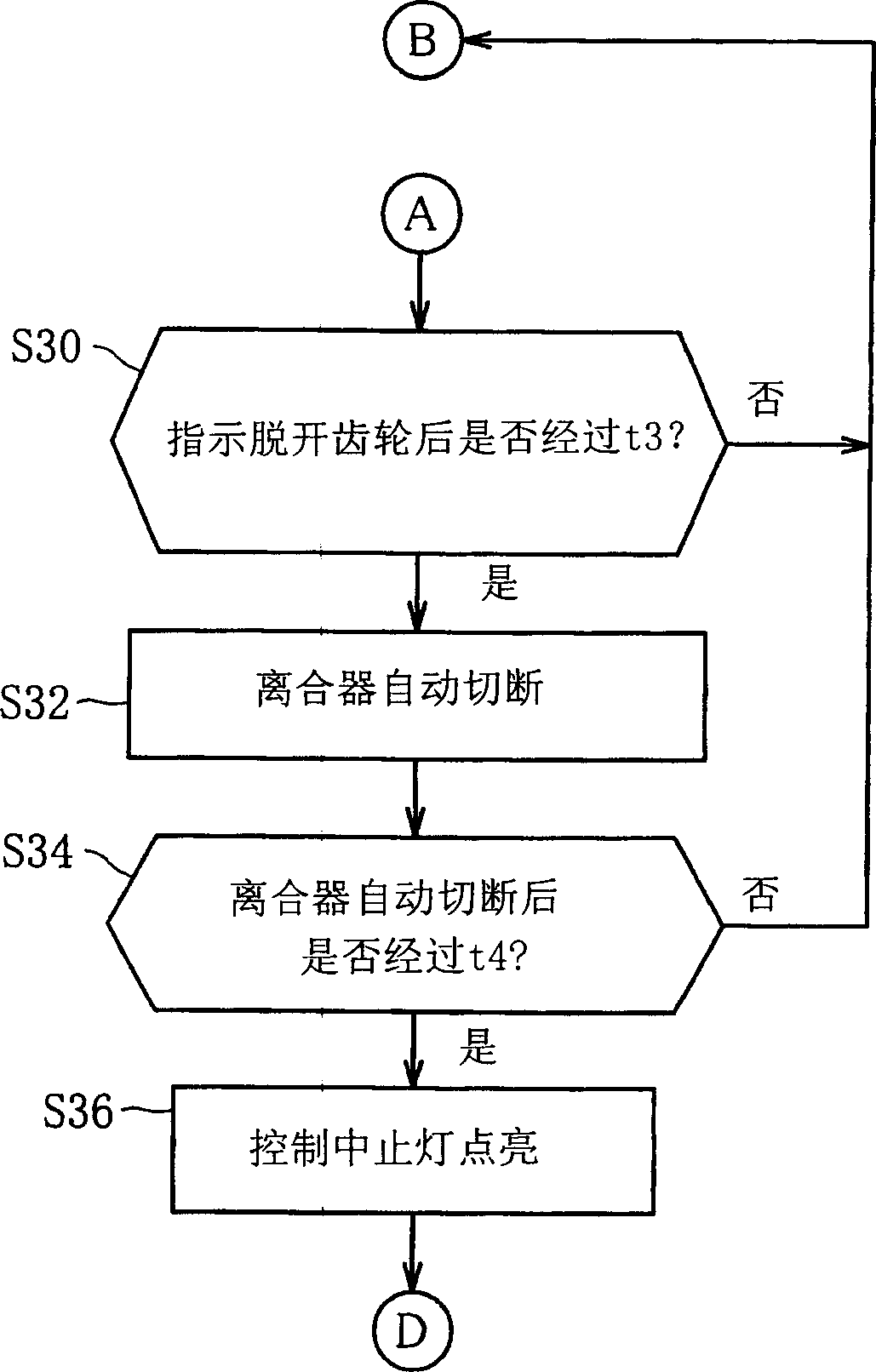

[0036] An embodiment of the present invention will be described below with reference to the drawings.

[0037] exist figure 1 In , the overall structure of a vehicle (passenger car, etc.) drive system to which the gear shift control device for a mechanical transmission of the present invention is applied is shown. The following is based on figure 1 The configuration of a vehicle drive system including the speed change control device for a mechanical transmission according to the present invention will be described.

[0038] As shown in the figure, a fuel injection pump device (hereinafter simply referred to as an injection pump) 6 for supplying fuel is provided in a diesel engine (hereinafter simply referred to as an engine) 1 . The injection pump 6 is a device for injecting fuel by operating the pump with the output of the engine 1 transmitted through a pump input shaft (not shown). The injection pump 6 has a control rack (not shown) for adjusting the fuel injection amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com