Folded-flex bondwire-less multichip power package

A technology of flexible substrates and assembly parts, which is applied in the field of multi-chip power modules, can solve the problems of expensive process, complex thermal channel design, reduce the high resistance effect of wire bonding, etc., achieve a wide heat dissipation area, improve heat dissipation, and increase heat dissipation channels Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

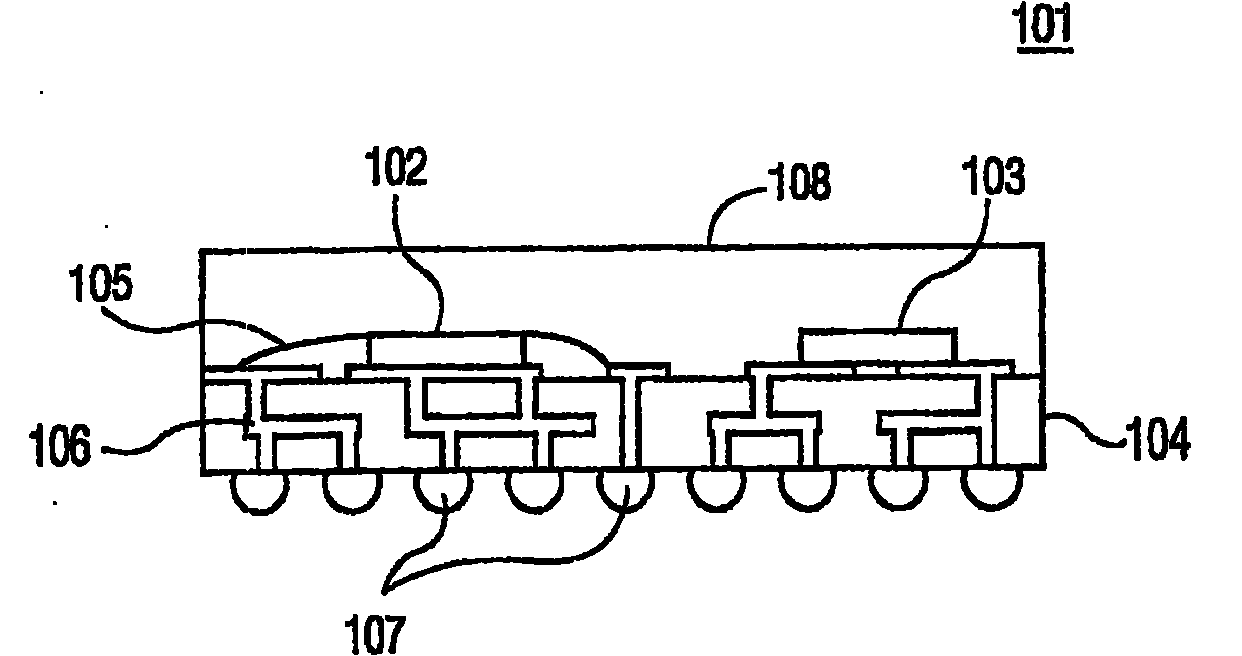

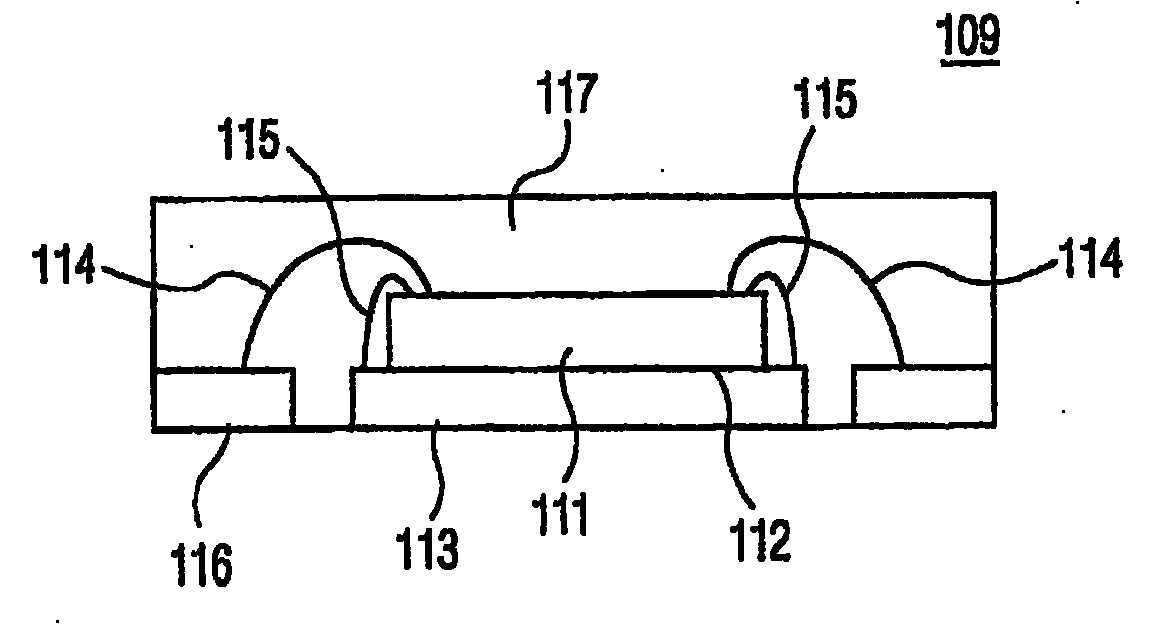

[0028] image 3 is an internal view of one embodiment of a folded flexible bondless leadless multi-chip power package in accordance with the present invention. Individual devices 301 , 301 ′, 301 ″, 301 ″′ etc. including semiconductor power dies as well as IC dies are attached to the main body portion 306 of the continuous flexible substrate 302 . Devices 301, 301', 301", 301"', etc. on the surface of each device die have device pads (not shown) with flip-chip bumps. Extended portions 303 and 303' of flexible substrate 302 are folded over devices 301 and 301' and devices 301" and 301"', respectively. This flexible substrate is equipped with copper contact pads on its bottom surface ( image 3 not visible in ) and connection 304 for attaching the circuit board. A molding compound is formed around the package in the shape 305 of an elongated rectangular box. A flexible substrate for semiconductor packaging is a stack of layers that typically includes a solder mask layer, a cop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com