Quantum minitype propeller using vacuum

A micro thruster and zero-point energy technology, applied in the direction of microstructure devices, relays, snap-action devices, etc., which are composed of components that move relative to each other, to achieve the effect of solving the problem of energy limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

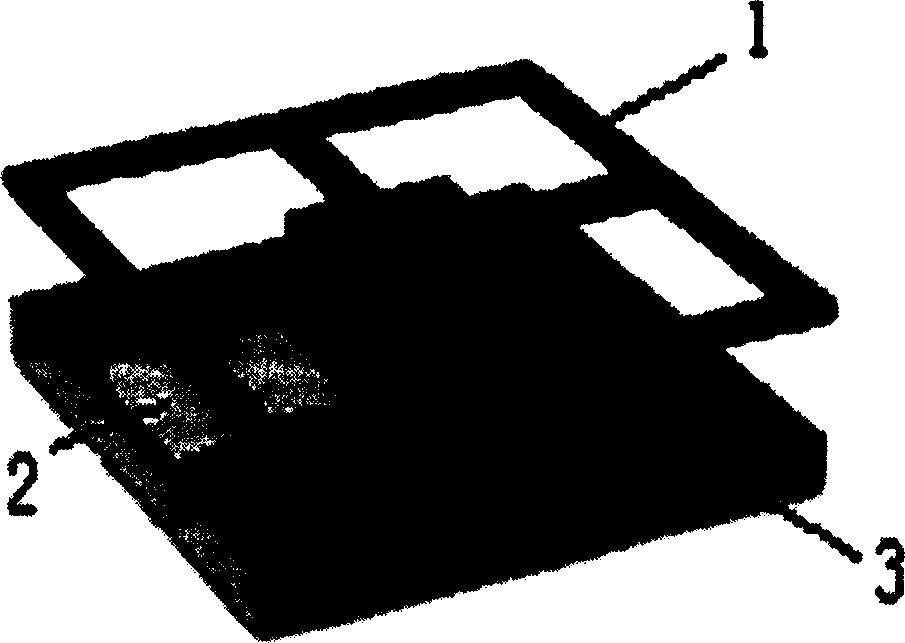

[0010] figure 1 The working process of the micro-propeller shown in is as follows: first, let the stopper 2 move horizontally to the right to block the microcavity above the base 3, so that the plane in the piston assembly 1 forms two parallel structures with the stopper 2, so that The Casimir force between the two is gravitational force, which attracts the piston assembly 1 to move downward, while the frame of the piston assembly 1 remains stationary, so that it just pulls the four cantilevers (equivalent to the function of springs) on it to follow the piston assembly The planes in the body 1 move downward together. When the plane in the piston assembly 1 moves to the bottom position, it can be considered that the elastic restoring force is equal to the Casimir force at this time, and the cantilever at this time has the largest elastic potential energy; 2. Move left horizontally, so that the piston 1 faces the microcavity on the base 3 to form a rectangular cavity structure. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com