Coaxial connector with a switch

A coaxial connector and switch technology, which is applied in the direction of connection, two-part connection device, and parts of the connection device, can solve the problems of high component cost and assembly cost, large number of components, complex structure, etc., so as to reduce the cost of components and assembly cost, good high frequency characteristics, the effect of simplified shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

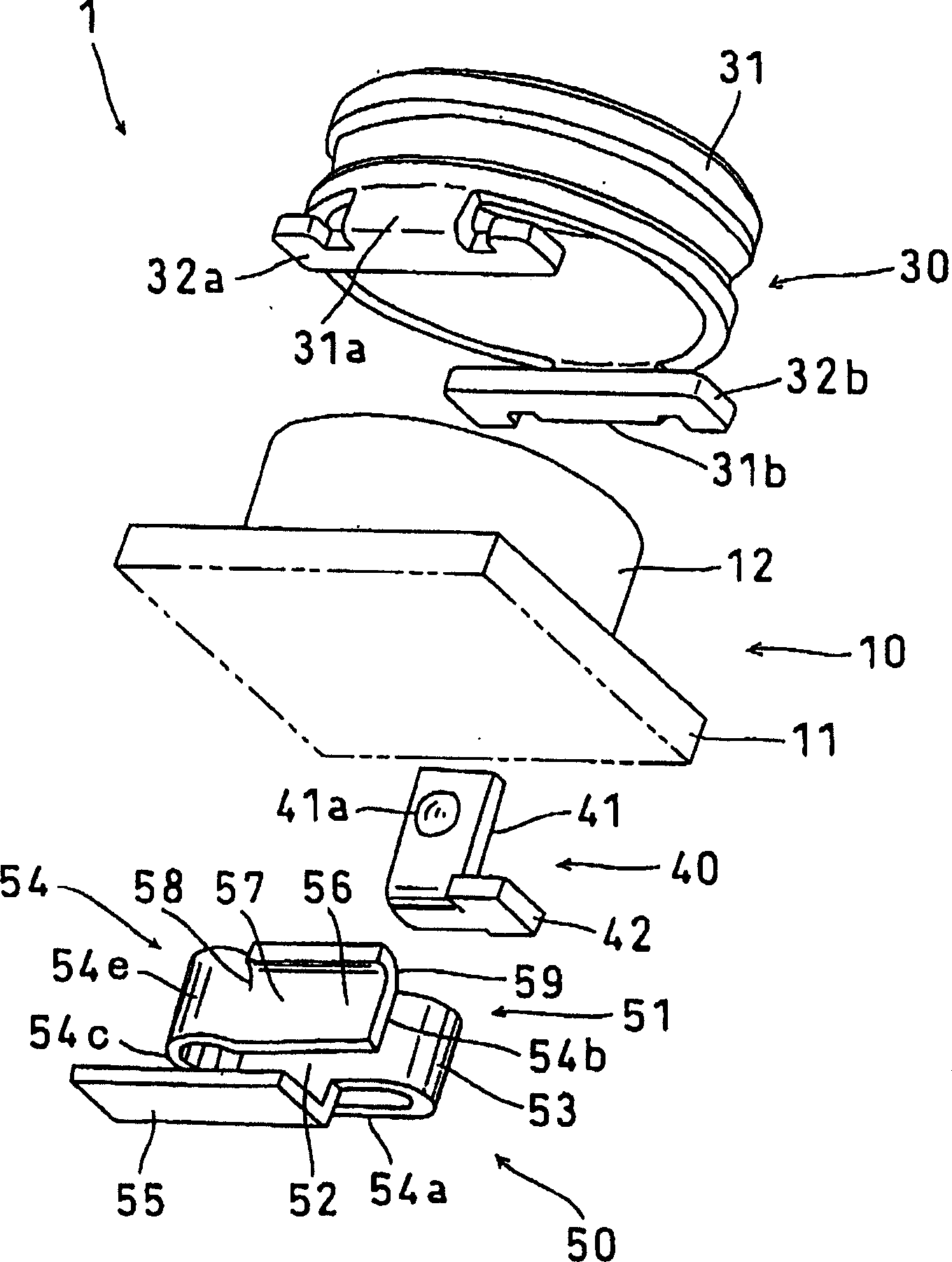

[0037] Below, refer to Figure 1 to Figure 10 A first embodiment of the present invention will be described. like figure 1 As shown, the coaxial connector 1 with a switch is constituted by only four parts of an insulating member 10 , an outer conductor case 30 , a fixed connection member 40 for switching, and a movable connection member 50 .

[0038] Next, each component will be described.

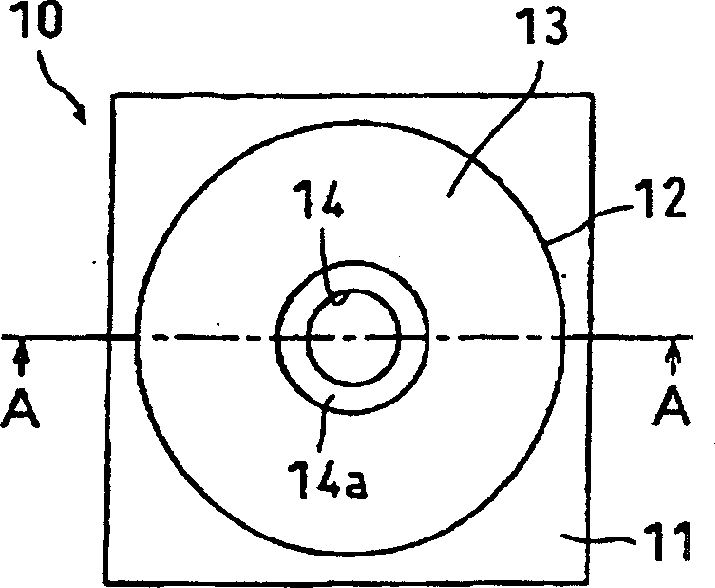

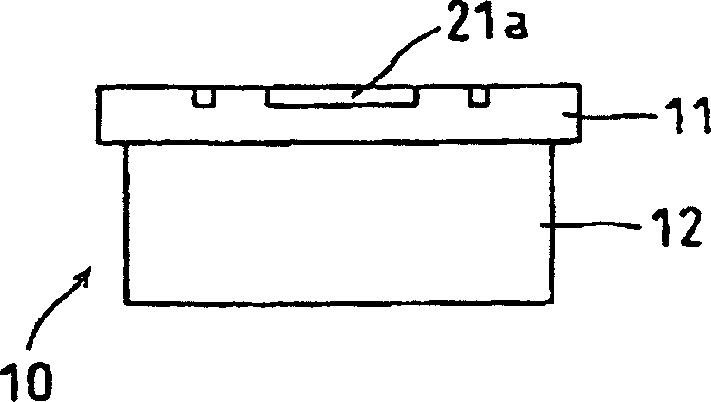

[0039] Insulation parts 10, such as figure 1 , as shown in FIG. 2 , is made of an insulating resin material (for example, LCP), and is formed into a cylindrical shape with a top integrally having a substantially rectangular parallelepiped pedestal 11 on the bottom side. The pedestal part 11 is formed in a square plate shape, and the length of one side is equal to the outer diameter dimension of the cylindrical insulating member main body 12 plus the thickness of the metal thin plate forming the outer conductor case 30, that is, the outer conductor case The outer diameter of the case bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com