Device for cleaning lid on coke-fired furnace

A technology for cleaning device and furnace cover, which is used in the heating of coke ovens, doors/closures of coke ovens, coke ovens, etc., and can solve the problems of difficult and close contact of scrapers, inability to use scrapers, and incomplete removal of scrapers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

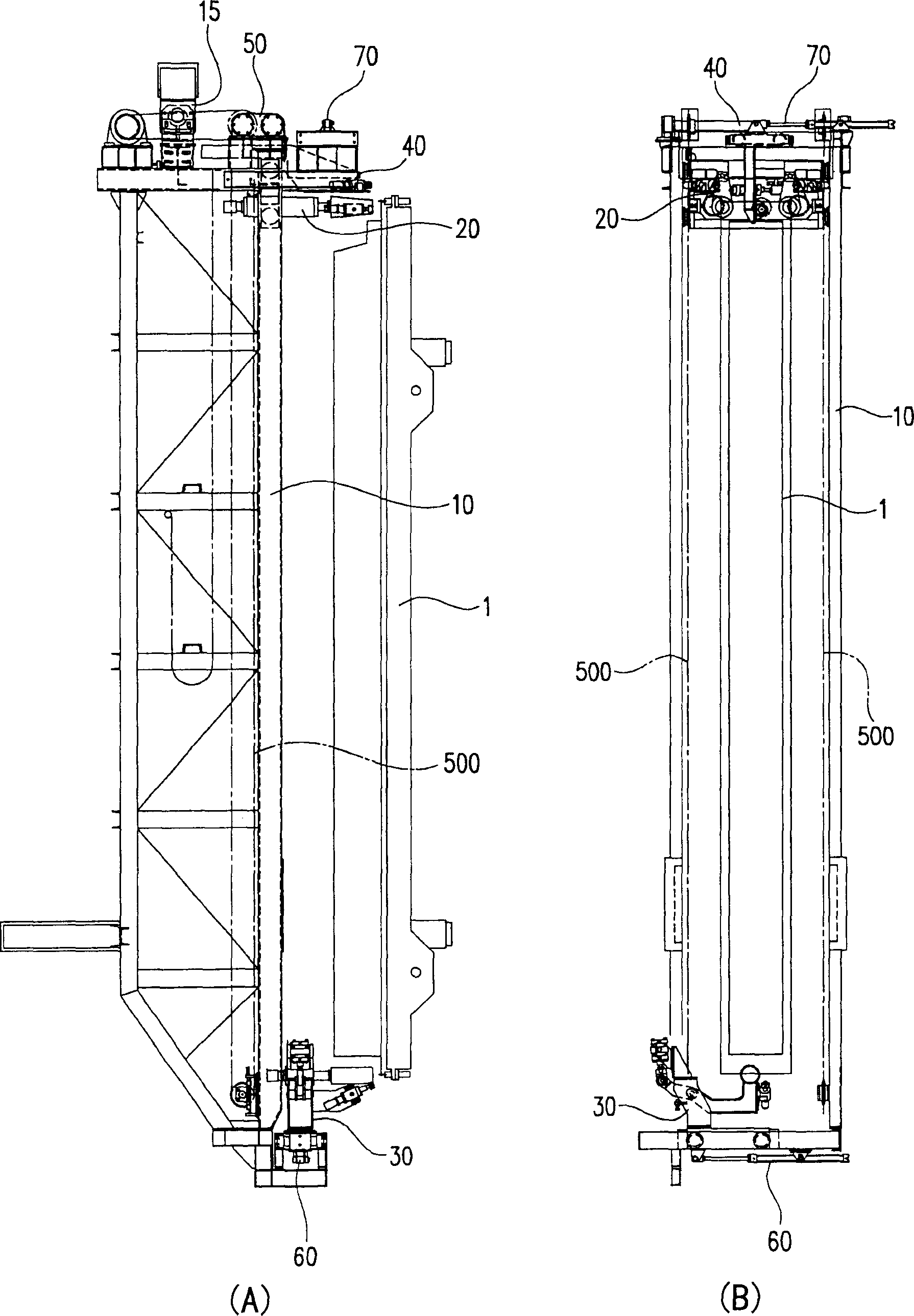

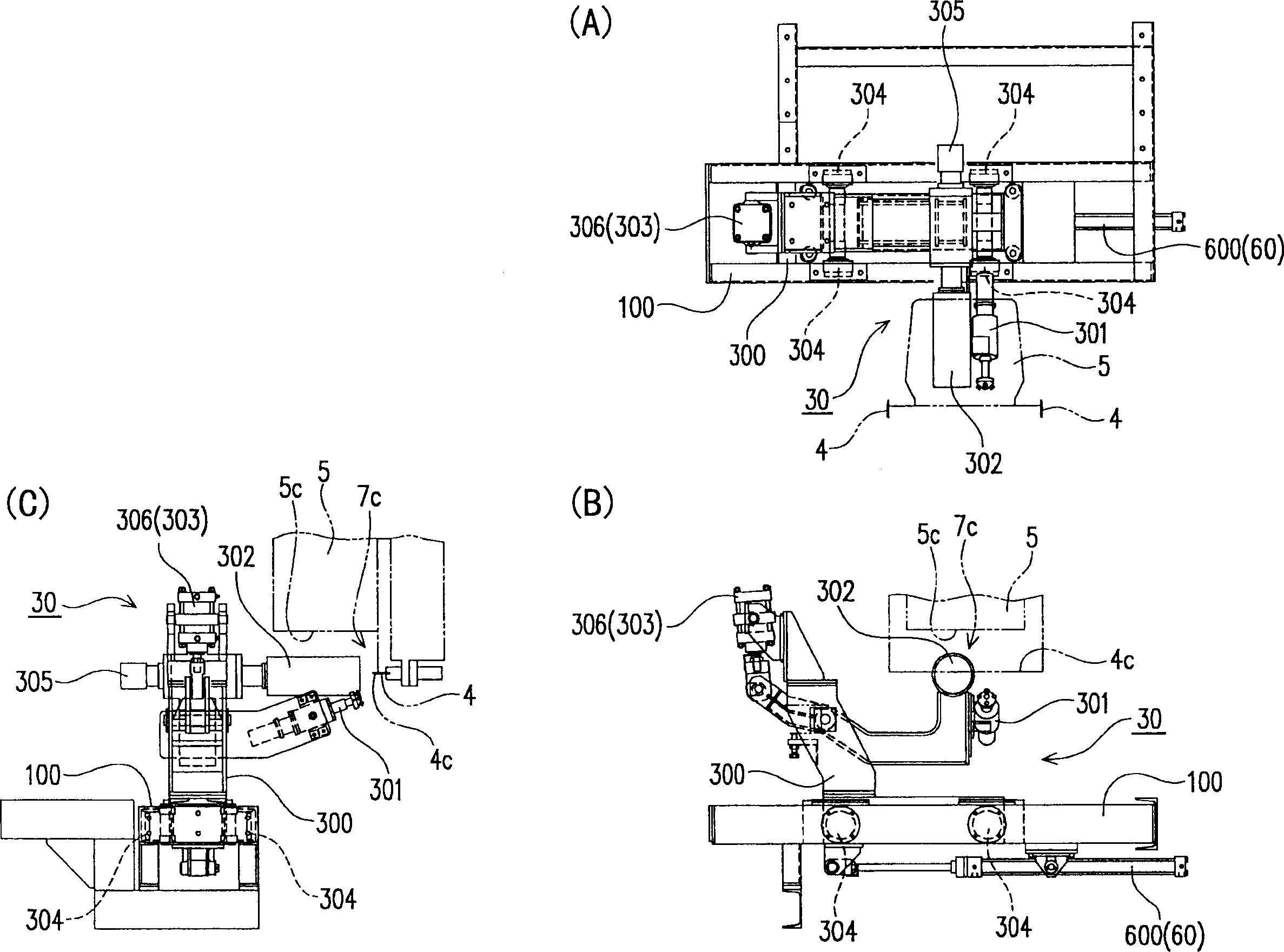

[0031] Hereinafter, a furnace roof cleaning device according to an embodiment of the present invention will be described with reference to the drawings. The furnace cover cleaning device of the embodiment of the present invention, such as figure 1 As shown, it is the side cleaner 20 for cleaning the left and right sides of the furnace cover 1 (removing attachments), the side cleaner 30 for cleaning the lower side of the furnace cover 1, the side upper cleaner 40 for cleaning the furnace cover 1, and the side surface for lifting and lowering. The driving device 50 of the sweeper 20, the driving device 60 that makes the following sweeper 30 traverse, and the driving device 70 that makes the upper sweeper 40 traverse are assembled on the main body frame 10 respectively, and the main body machine is passed through the suspension device 15. The frame 10 is installed on the structure of the mobile machine (extruder or guide car).

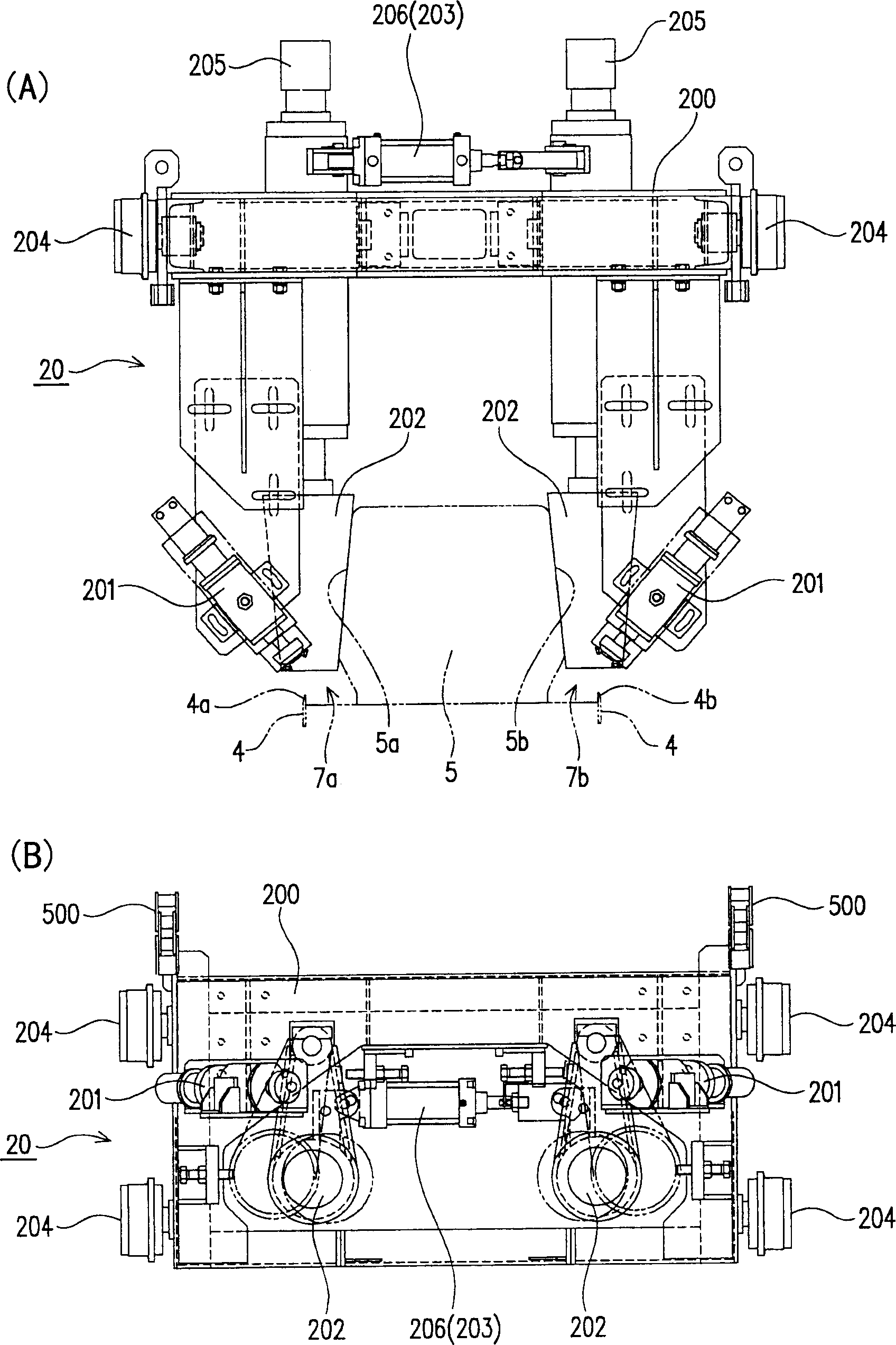

[0032] like figure 2 As shown, the side sweeper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com