Computer measurement and control system for die-casting machine

A technology of measurement and control system and die-casting machine, which is applied in the field of measurement and control system and its control of die-casting machine, digital manufacturing, and can solve problems such as wasting energy and reducing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

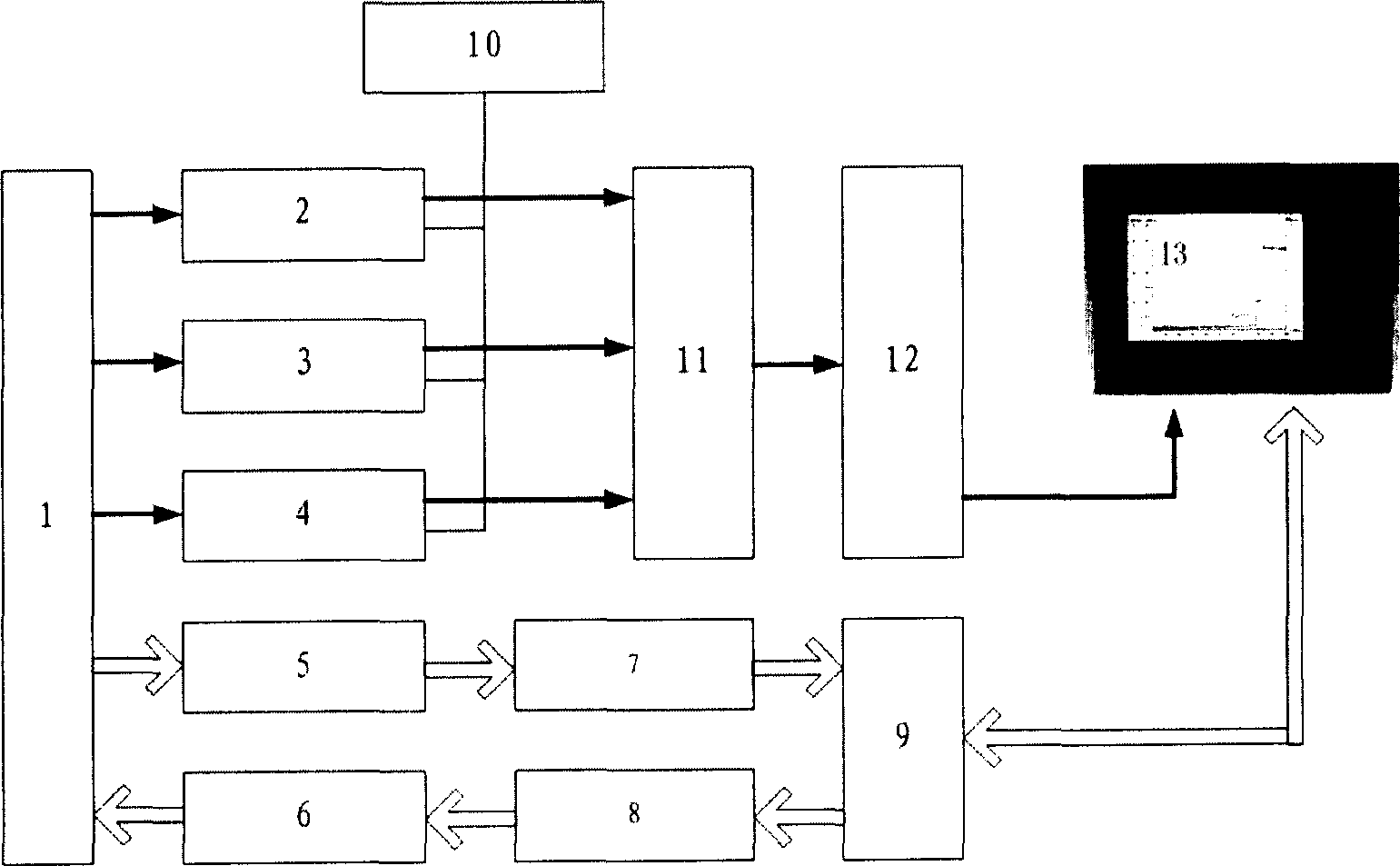

Method used

Image

Examples

example 1

[0048] Example 1: Debugging process in "manual" mode (delayed unloading function)

[0049] When debugging a certain technological process, the execution process between any two actions at this time is as follows: Figure 5 shown.

example 2

[0050] Example 2: Batch processing of castings in "automatic" mode:

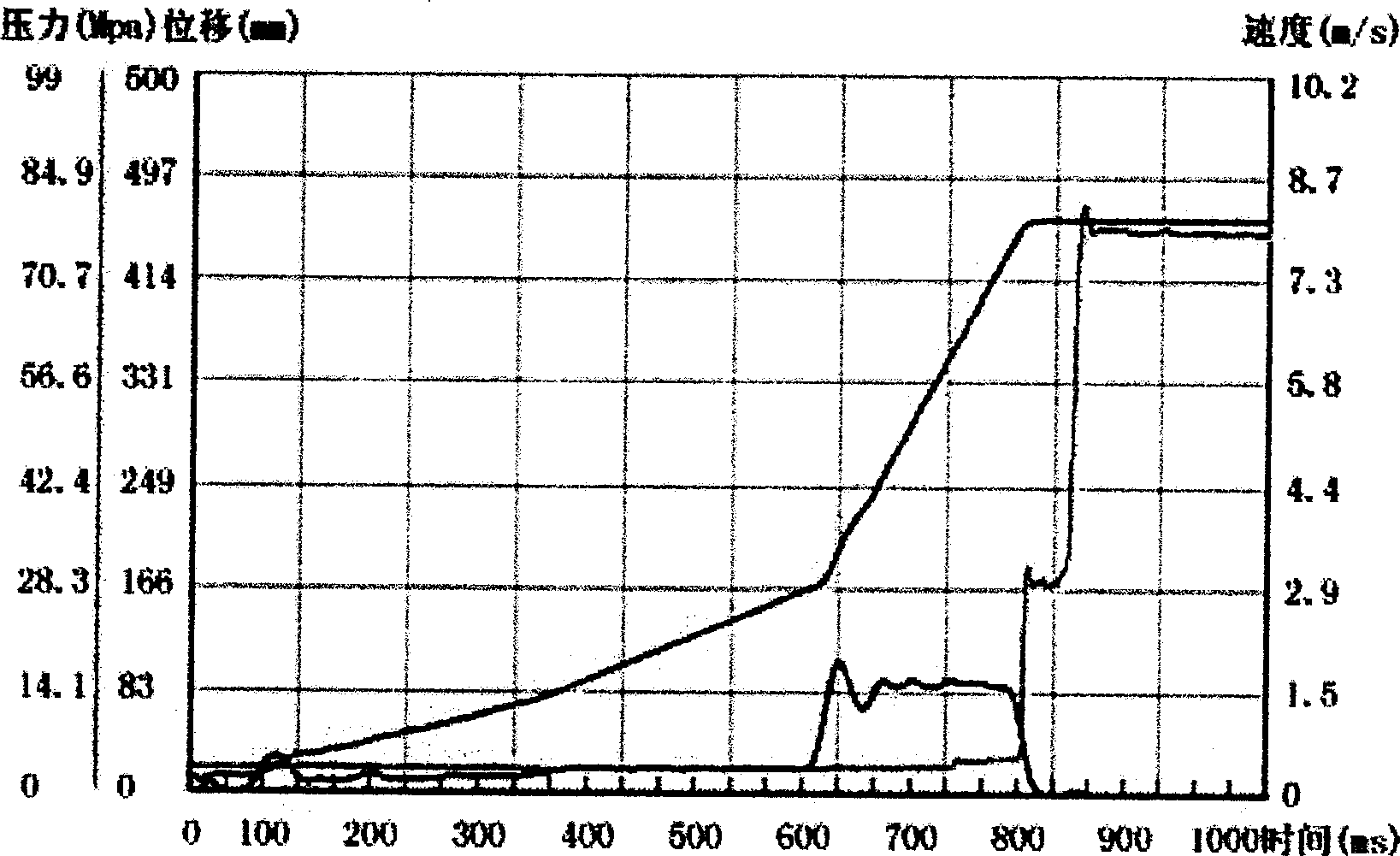

[0051] The die-casting machine starts the die-casting action according to the set die-casting process. At the same time, the computer samples the analog signals of various sensors, and through A / D data conversion, the sampling of the injection stroke, injection speed and injection pressure is displayed on the computer screen in real time. data curve ( image 3 ), and record and calculate various technical parameters of the current working conditions, such as mold clamping force, maximum pressure, pressure building time, etc.; when a product die-casting is completed, the computer will automatically save the test data with the die-casting production time of the product as the file name save.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com