Sheet material identification apparatus and image forming apparatus therewith

A material identification and imaging device technology, applied in printing devices, printing, office printing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

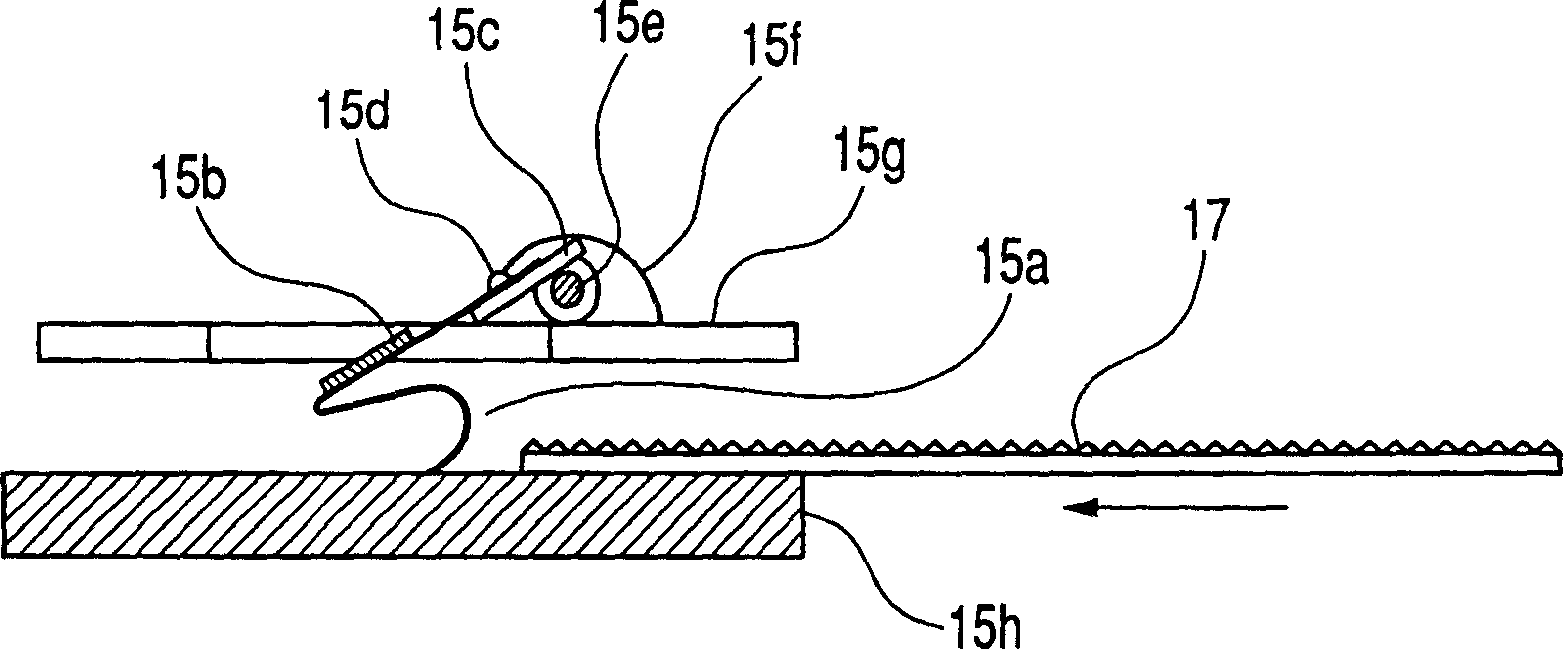

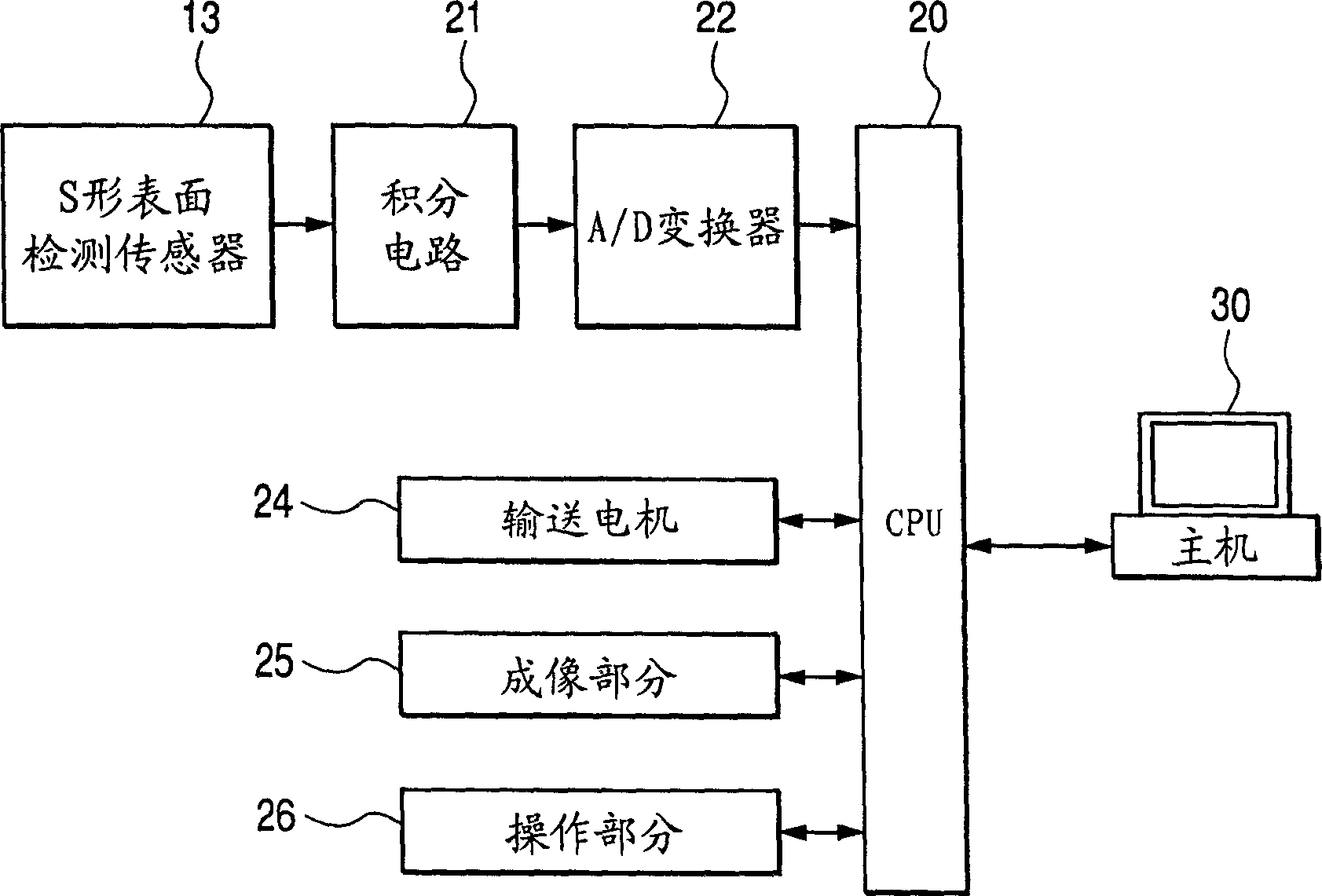

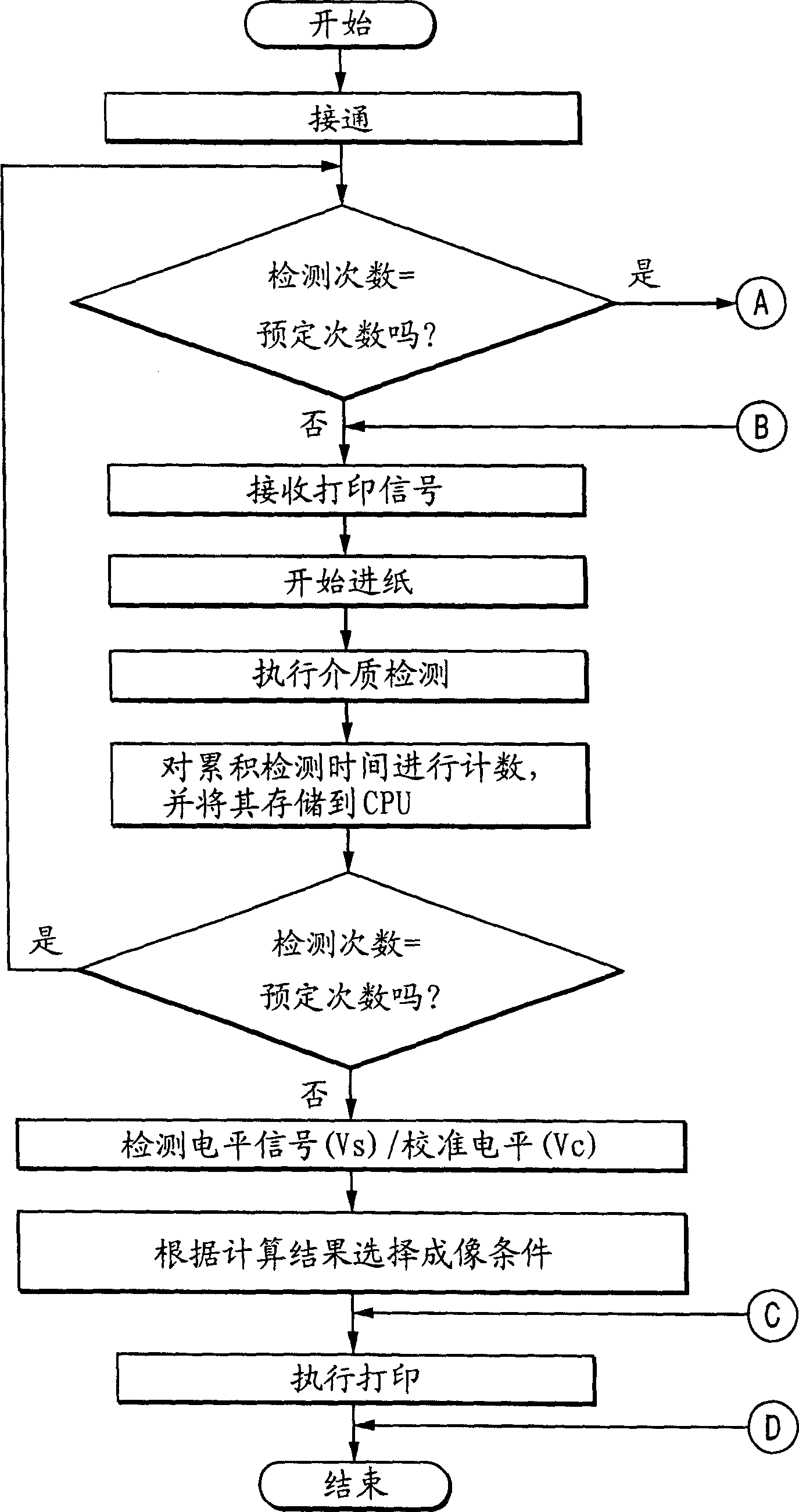

[0090] Figures 1 to 5 They are the sectional view, control block diagram, flow chart, corrected durability result, and sectional view of the calibrated sheet storage unit of the sheet material identification device according to Embodiment 1 of the present invention. here, in figure 1 , the same reference numerals are used for the Figure 7A corresponding components.

[0091] In this example, if figure 1 As shown, a calibration sheet 17 whose surface has been roughened to simulate a rough paper is conveyed to a sheet conveying plane portion 15a in contact with a probe tip portion of an S-shaped surface detection sensor 15, so that the sheet is detected according to the sensor. signal level to calibrate the sensor.

[0092] Regarding the main dimensions of each of the configuration parts above, the width of the probe is 4mm, the size of the opening in which the probe moves up and down is 6mm x 6mm, the length of the flat portion of the probe is 15mm, and the dimensions of...

Embodiment 2

[0101] Figure 10 11 and 11 are respectively a sectional view and a flow chart of the sheet material identification device according to Embodiment 2 of the present invention. here, in Figure 10 in, with figure 1 Corresponding elements are provided with the same reference numerals.

[0102] In this example, if Figure 10 As shown, the difference is that the double-sided foil calibration foil 17' has two sides, that is, one side is roughened on one side of the foil to resemble rough paper, and the other is smooth on the opposite side. The smoothness of the paper. This calibration sheet 17' is conveyed to the sheet conveying plane portion 15a in contact with the probe tip portion of the S-shaped surface detecting sensor 15 each time with the front side once and the back side once in total, so that each paper is detected according to the sensor. The sensor is calibrated based on the signal level behind the surface, and the main dimensions of the configuration components and...

Embodiment 3

[0106] Figure 12A , 12B and 12C are explanatory diagrams of a method of mounting a print cartridge in an electrophotographic system, an explanatory diagram of a calibration sheet setting method, and an explanatory diagram of a cartridge replacement method, respectively, relating to Embodiment 3 of the present invention.

[0107] In this embodiment, as shown in Fig. 12, conventionally, a cartridge 11' having an alignment sheet 17 mounted on the top surface of the cartridge is used as the above-mentioned periodical correction guide. When the printer main body 18 is used for the first time, the top cover 18a is opened in the direction of the arrow, and then the cartridge 11' with the calibration sheet is installed. The printer is configured so that the printer is unusable until a signal from the printer main body requesting calibration using the calibration sheet belonging to the cartridge is notified to the printer main body display portion or the host computer side. And, if ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com