Multi-tube type dyeing machine for rope-like fabric

A dyeing machine, multi-tube technology, applied in the direction of liquid/gas/steam rope fabric processing, liquid/gas/steam jet propulsion fabric, etc., can solve the problem of difficult to obtain balanced guarantee, multi-storage tank overflow dyeing The level dyeing property of the machine system is difficult to control, etc., so as to achieve the effect of reducing the time required for dyeing, ideal level dyeing property and shortening the process cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be further described below with reference to the accompanying drawings.

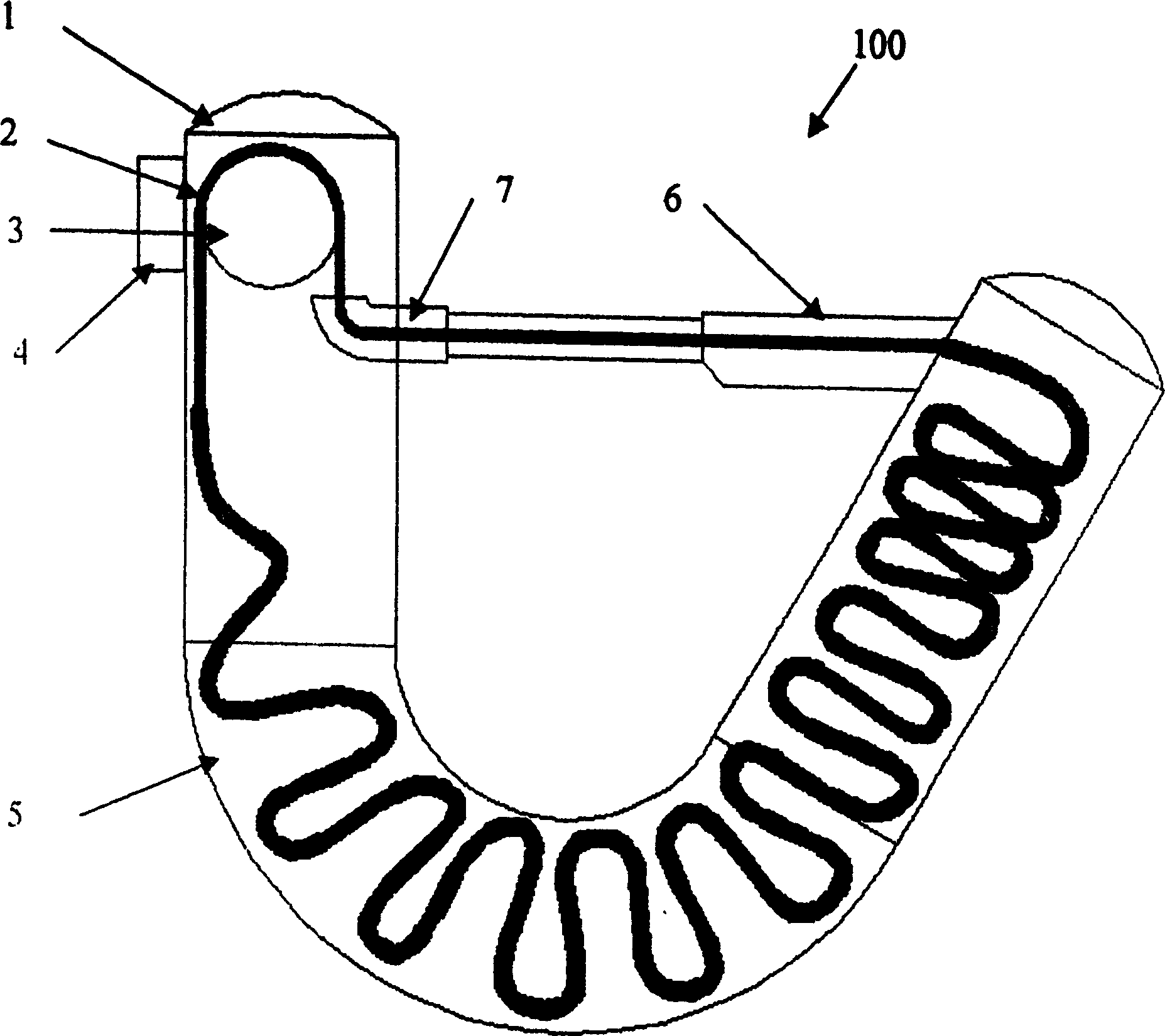

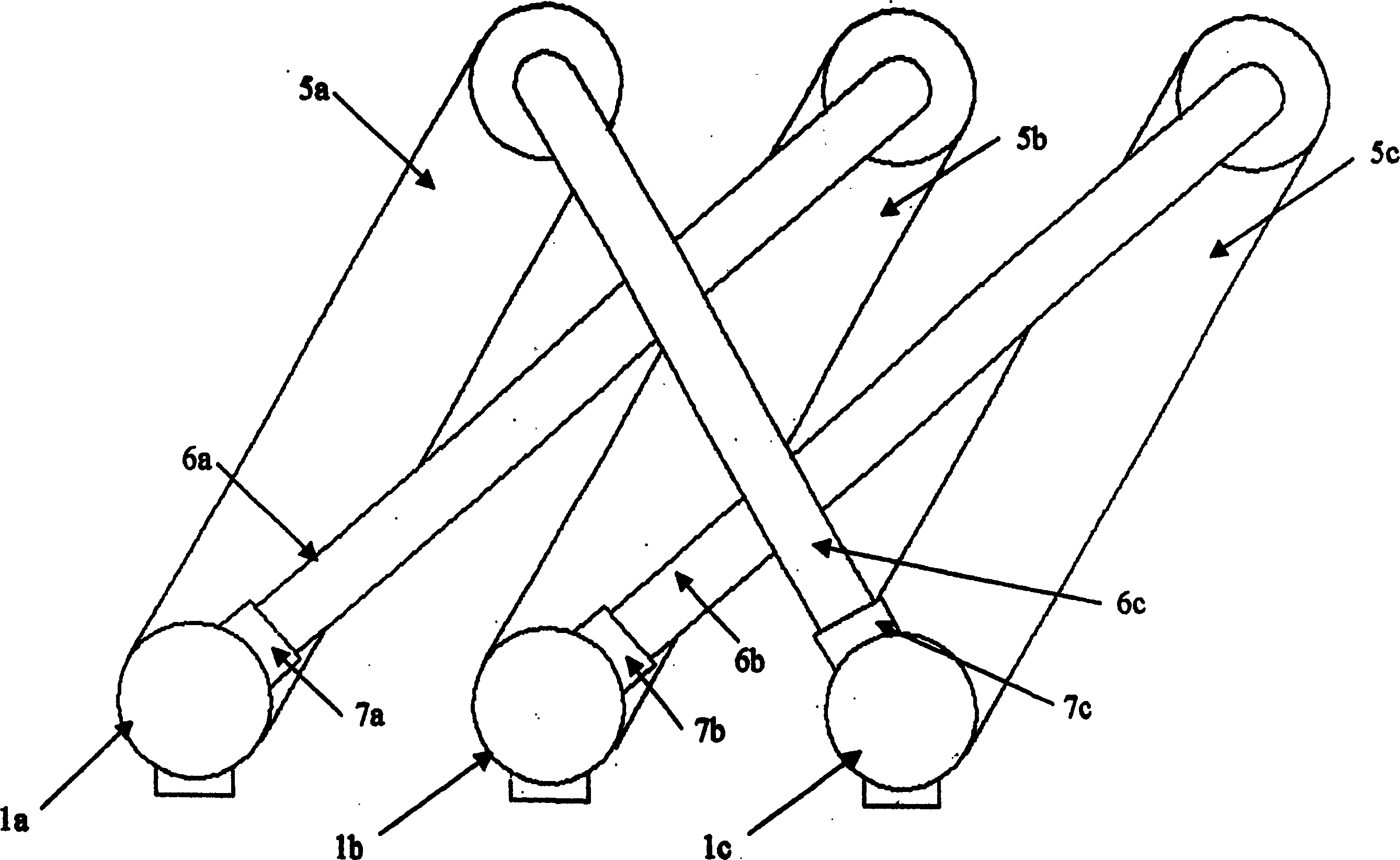

[0019] Such as Figure 1 and Figure II The multi-tubular single rope fabric dyeing machine 100 shown in the present invention includes a series overflow dyeing machine system, which is composed of three independent typical overflow dyeing machine systems. The present invention comprises a series of spray nozzles 6, a lifting drum 3, and a cloth storage cylinder body 5. The cloth storage cylinder body 5 is a half-moon curved circular cylinder, and each cloth storage cylinder body 5 front ends have a working door 4 for general cloth entry, cloth output and other general operating purposes. There is a lifting drum 3 in the top 1 of each cloth storage cylinder body front end to lift the rope-like fabric upwards from the cloth storage tank at the middle part of the cloth storage cylinder body 5 and deliver it to the nozzle 7. There is a nozzle conduit 6 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com