Symmetry type three-roller plate roll barrel no-remain straight flange rolling technique

A symmetrical, roll-to-roll technology, applied in the field of metal machining, can solve the problems of corner waste, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

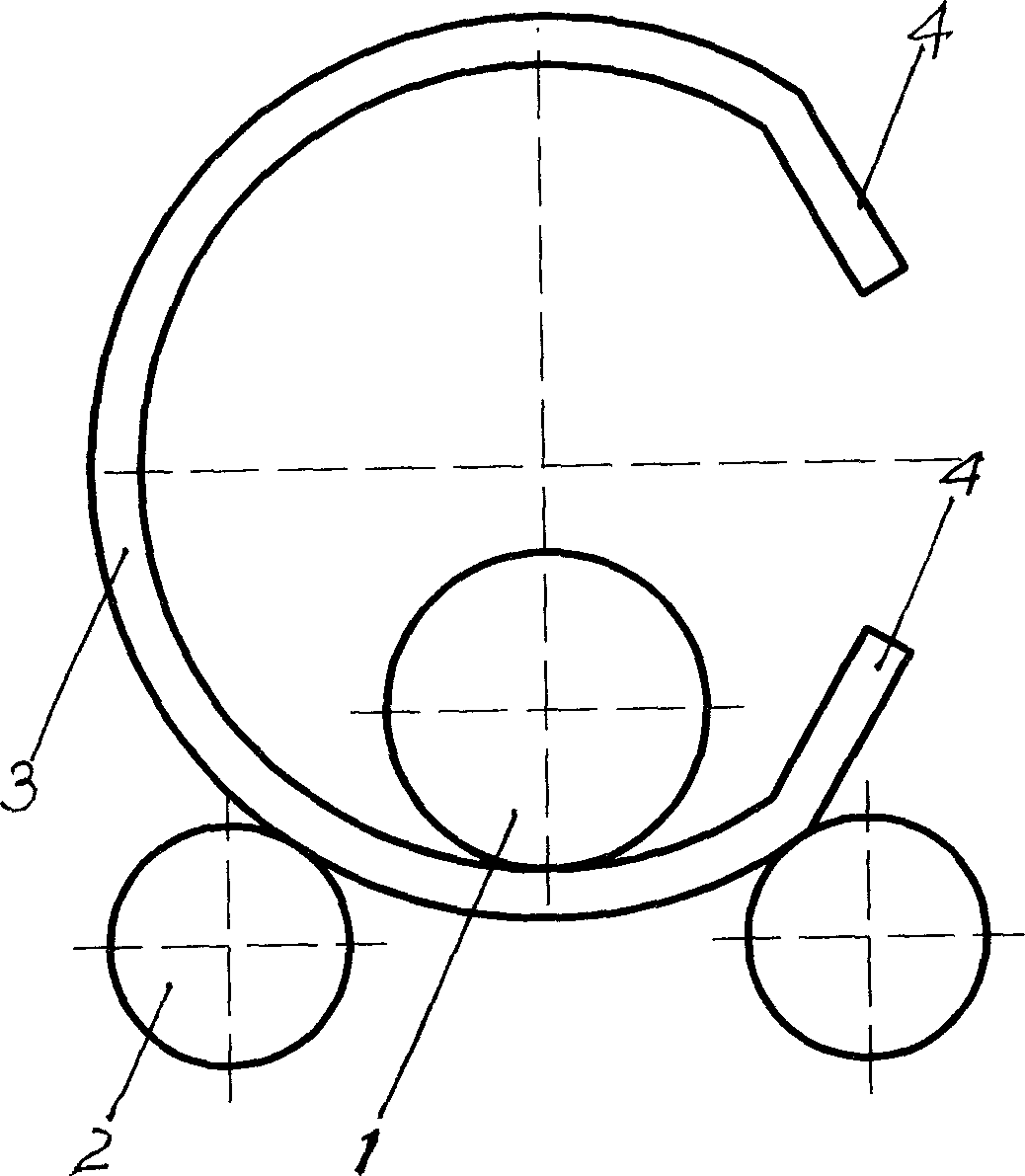

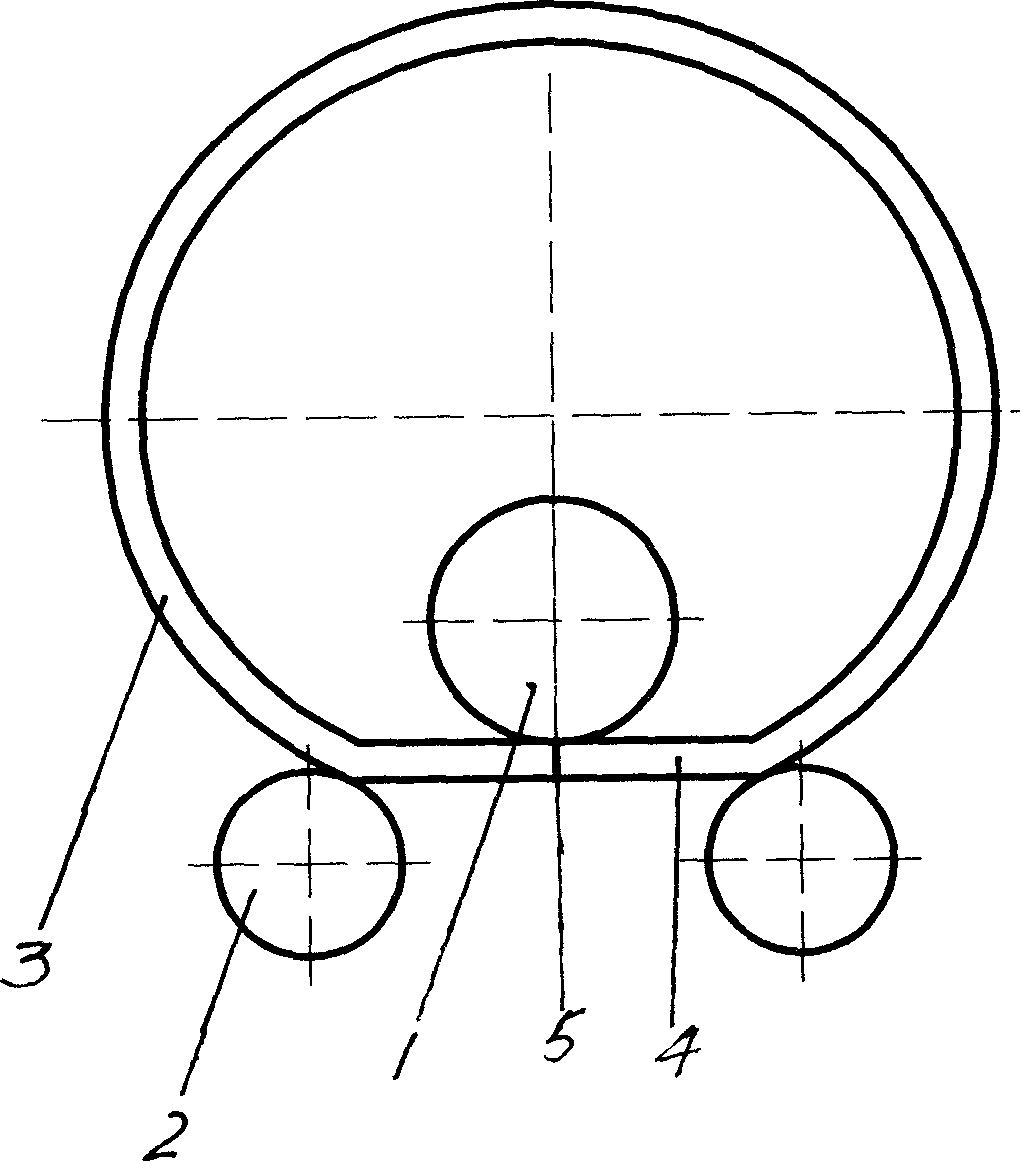

[0007] The symmetrical three-roll plate rolling machine mainly consists of an upper roll and two lower rolls. The upper roll can rotate left and right on the steel plate, and the lower roll is the driving roll, which can rotate forward and reverse. In the past, the process of rolling steel plates is: put the steel plates including the remaining straight sides between the upper roll 1 and the lower roll 2, and then the upper roll 1 bends the steel plates downward. At this time, the inner layer of the bent part of the steel plate is subjected to When the outer layer is under tension, the bending distance in the middle of the two lower rollers 2 is the largest, reaching a plastic bending state, and then the two lower rollers 2 are driven to rotate, and the steel plate moves left and right by means of the friction between the steel plate and the rollers, and the At the same time, the upper roller 1 rotates, so that the steel plate becomes an arc-shaped plate with the same curvature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com