Photolithography device and method for manufacturing the same

A lithography and accommodating device technology, applied in microlithography exposure equipment, photolithographic process exposure devices, patterned surface photolithographic process, etc. Imaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

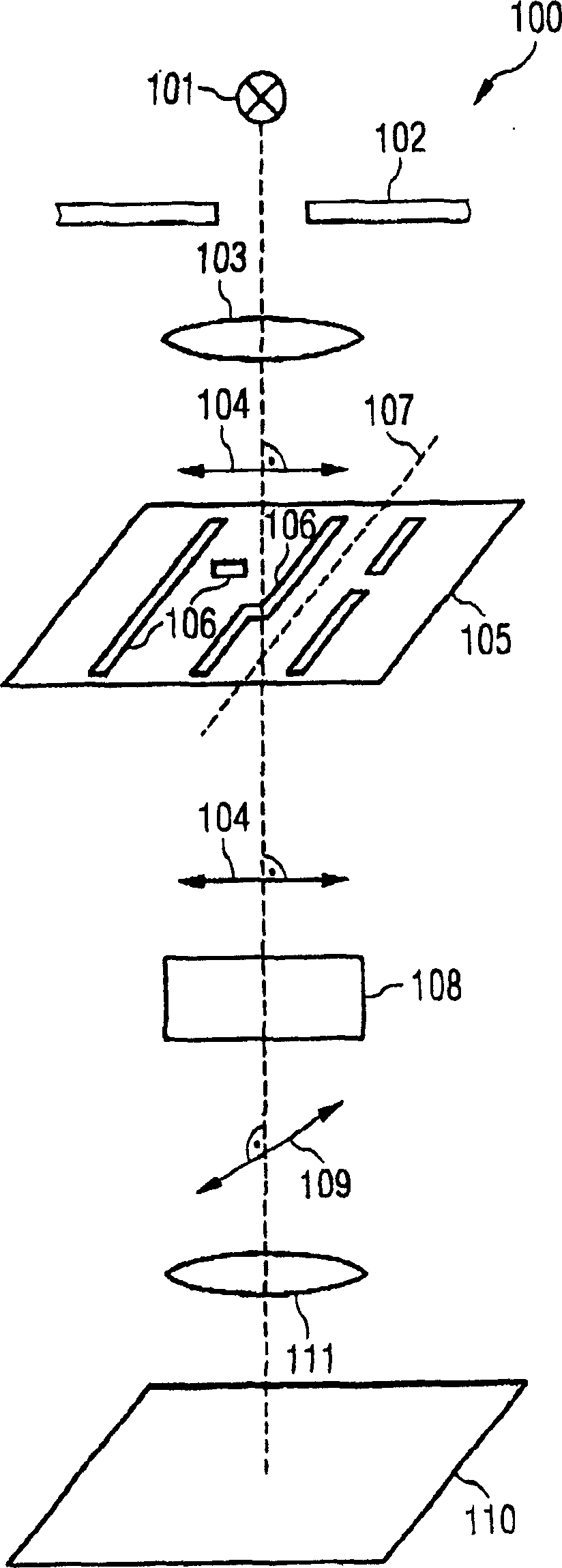

[0056] Next, with figure 1 And a photolithographic apparatus 100 is described according to a preferred embodiment of the present invention.

[0057] figure 1 The illustrated lithographic apparatus 100 comprises an electromagnetic radiation source 101, for example an ArF radiation source, which emits electromagnetic radiation with a wavelength of 193 nm. The light system emitted from the electromagnetic radiation source 101 is linearly polarized and has a polarization vector 104 . The generated electromagnetic radiation is directed through an aperture 102 and a lens 103 onto a mask 105 .

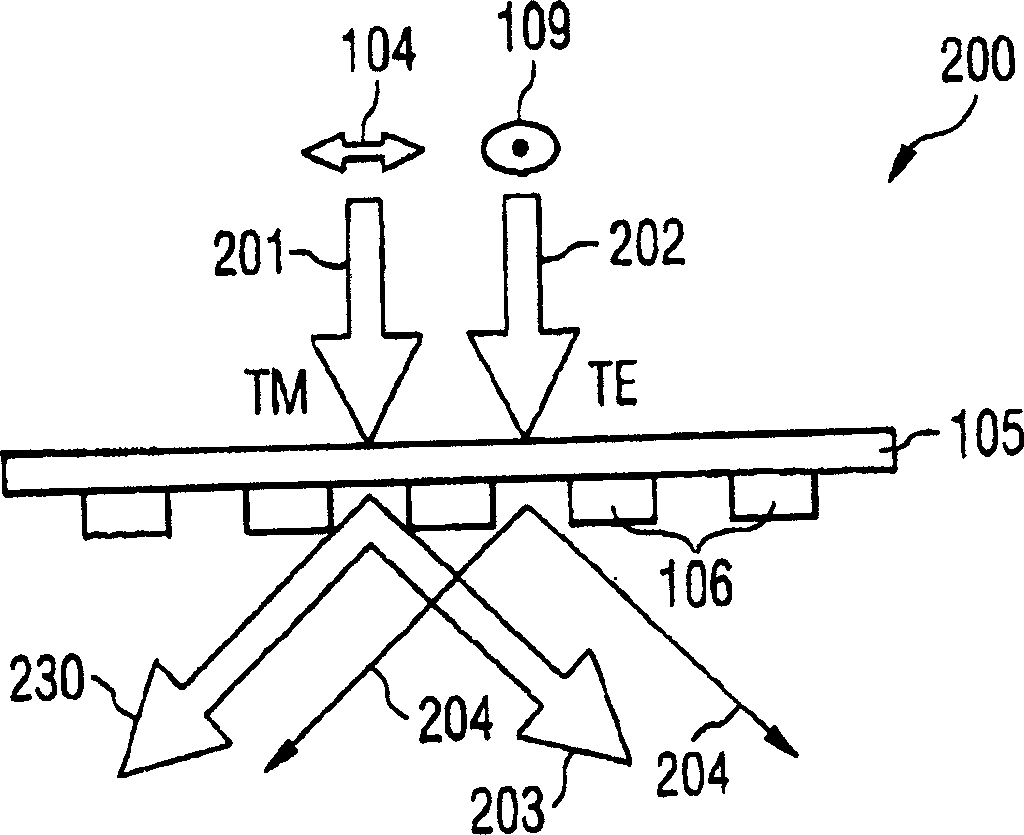

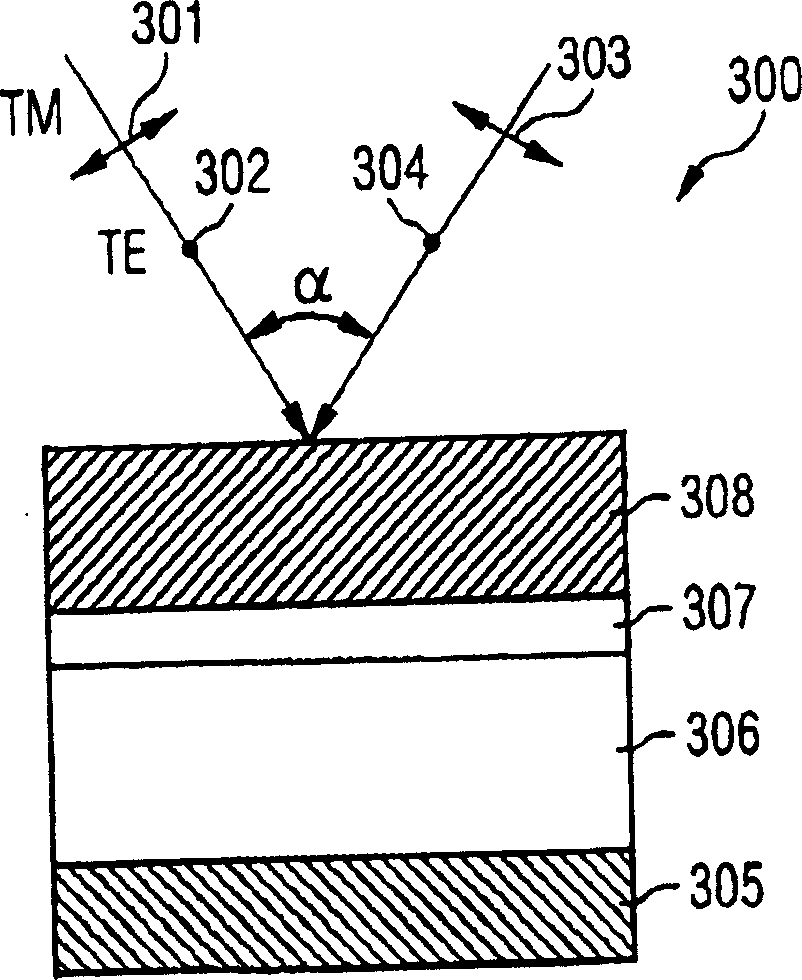

[0058] The photomask 105 includes a plurality of structures 106 to be formed on a silicon wafer 110 . The structure 106 comprises different components, which are generally arranged along an extension direction 107 . Electromagnetic radiation is absorbed by structures 106 and passes through regions between structures 106 . The first polarization vector 104 is substantially perpendicular t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com