Novel NIR-II diagnosis and treatment integrated silicon-carbon nanoprobe and preparation method thereof

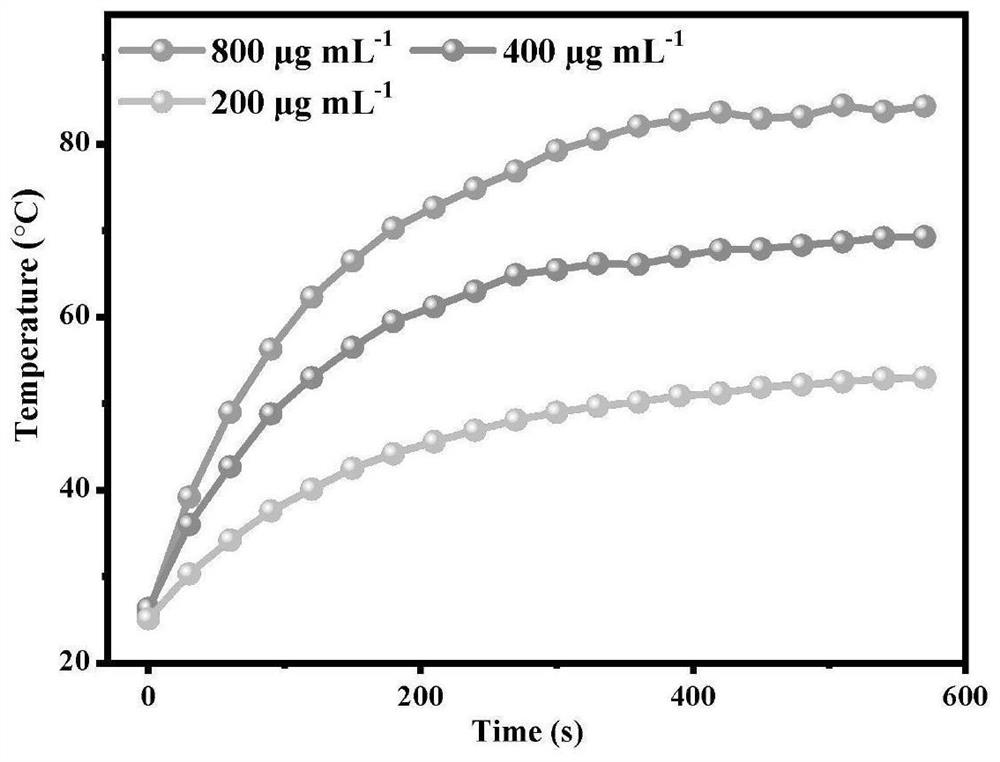

A nano-probe and carbon nano-technology, applied in the field of nano-biomedical material preparation, can solve problems such as difficulty in penetration, and achieve the effect of improving the degree of enrichment and improving the performance of imaging and treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A method for preparing a novel NIR-II integrated silicon-carbon nanoprobe for diagnosis and treatment, comprising the following steps:

[0036] S1. According to the molar ratio of deionized water: template agent: aluminum source: sodium hydroxide: silicon source = 10.02~16.67: 1.15~1.91: 1.25~2.08: 0.12~0.20: 1.99~3.33; deionized water, template agent Mix with aluminum source to form a mixed solution, stir at room temperature for 30 minutes; add 2 mol / L sodium hydroxide solution to the mixed solution, and stir for 30 minutes; add silicon source to it under stirring, and stir for 2 hours to form a white gel mixed solution ;

[0037] S2. Move the white gel mixed solution prepared in S1 into a polytetrafluoroethylene container, then place it in a reaction kettle, seal it, and place the reaction kettle in a thermostat to heat it tightly, with a heating temperature of 170°C, constant temperature, heat preservation, static Crystallize for 60 hours to form a crystallized gel ...

Embodiment 1

[0046] Take 83.33g of sodium hydroxide and 1L of deionized water, add them into a beaker and mix them thoroughly, transfer the mixed solution to a volumetric flask, and prepare a sodium hydroxide solution with a concentration of 2moL / L for later use;

[0047] Take 8.333g of sodium hydroxide and 1L of deionized water, add them into a beaker and mix them thoroughly, transfer the mixed solution to a volumetric flask, and prepare a sodium hydroxide solution with a concentration of 0.2moL / L for later use;

[0048] Take 135mL of deionized water, 155mL of tetraethylammonium hydroxide, and 2.565mg of sodium metaaluminate into a beaker in order to fully mix, stir at room temperature for 30min, add 30mL of 2mol / L sodium hydroxide solution to the mixed solution, stir for 30min, and take Add 30 g of white carbon black into the above mixed solution under stirring, and stir for 2 hours to form a white gel mixed solution;

[0049] Move the white gel mixed solution into a polytetrafluoroethyl...

Embodiment 2

[0053] Take 83.33g of sodium hydroxide and 1L of deionized water, add them into a beaker and mix them thoroughly, transfer the mixed solution to a volumetric flask, and prepare a sodium hydroxide solution with a concentration of 2moL / L for later use;

[0054] Take 8.333g of sodium hydroxide and 1L of deionized water, add them into a beaker and mix them thoroughly, transfer the mixed solution to a volumetric flask, and prepare a sodium hydroxide solution with a concentration of 0.2moL / L for later use;

[0055] Take 80mL of deionized water, 100mL of tetraethylammonium hydroxide, and 1.54mg of sodium metaaluminate into a beaker in order to fully mix, stir at room temperature for 30min, add 18mL of 2mol / L sodium hydroxide solution to the mixed solution, stir for 30min, and take Add 20 g of white carbon black into the above mixed solution under stirring, and stir for 2 hours to form a white gel mixed solution;

[0056] Move the white gel mixed solution into a polytetrafluoroethylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

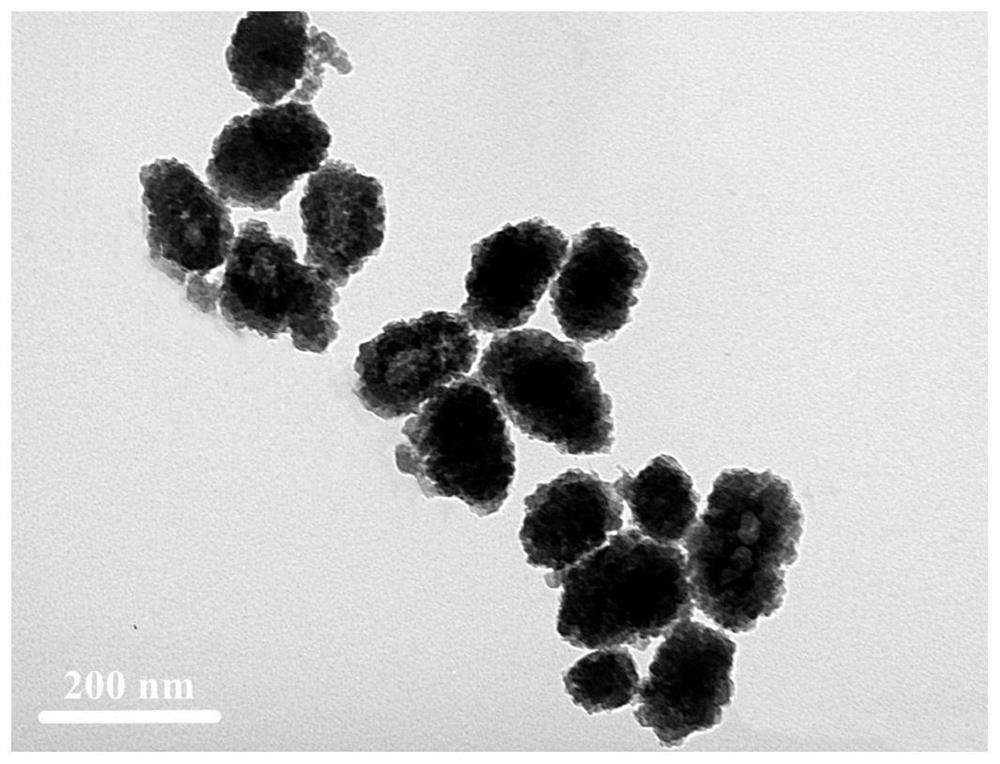

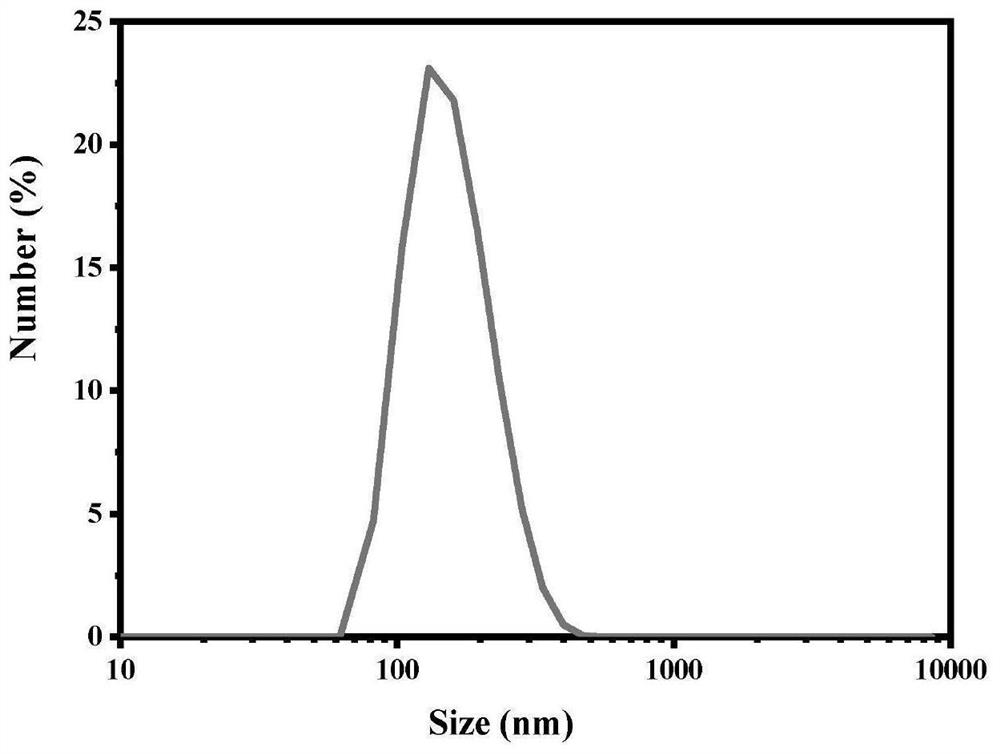

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com