Method and device for cooling ultrasonic transducers

An ultrasonic transducer and transducer technology, which is applied in the directions of sound-producing instruments, fluids that utilize vibration, instruments, etc., can solve the problems of reducing heat removal efficiency, reducing efficiency, preventing continuous operation of ultrasonic transducers, etc. Effect of Heat Removal Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

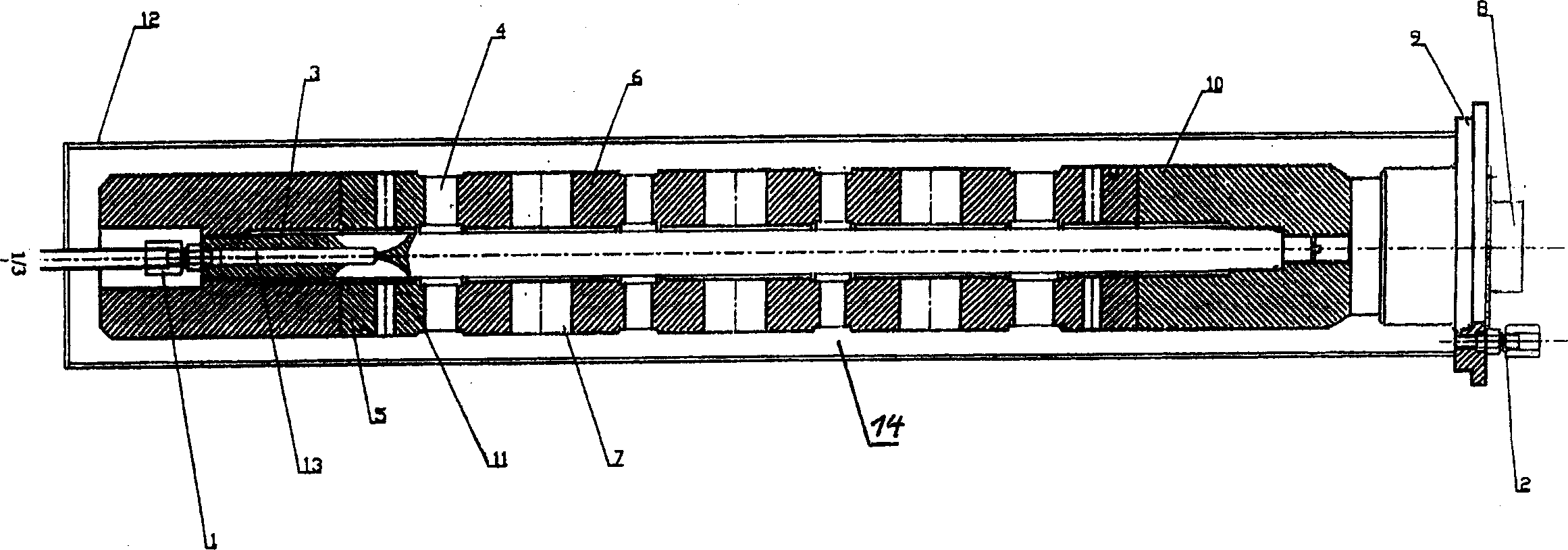

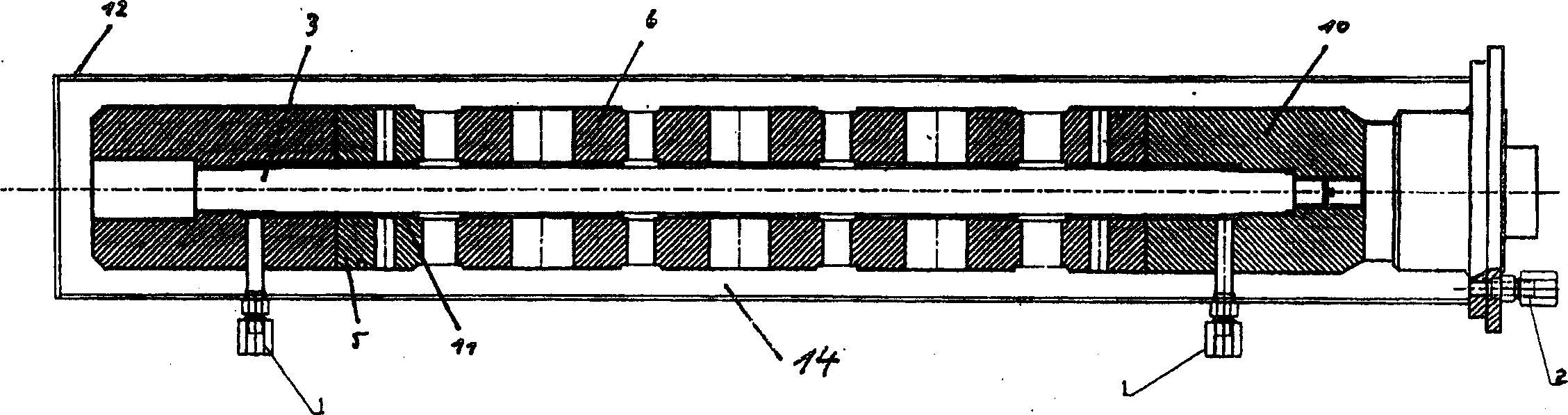

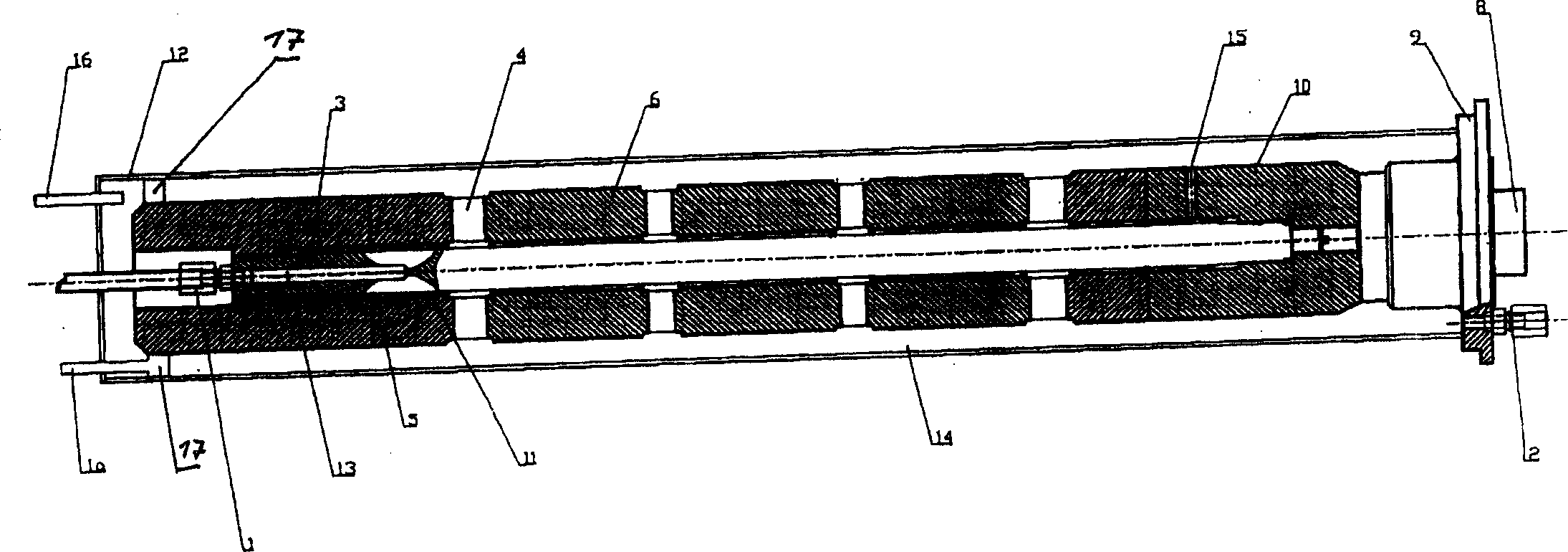

[0036] figure 1 A schematic longitudinal cross-section of an ultrasound transducer is shown, including a device for cooling the ultrasound transducer according to the invention. The ultrasound transducer is formed from cylindrical transducer bodies 5 , 6 and a piezoelectric stack 4 arranged between the end faces of the respective transducer body. Several of the transducer bodies 5 , 6 are formed into a single transducer body 6 in which a separate piezoelectric stack 4 is arranged on each end face. One of the individual piezoelectric stacks 4 is connected to one of the transducer bodies 5 and forms a lambda / 2 oscillator with either half of one of the single transducer bodies 6 or halves of both single transducer bodies 6 . The transducer bodies 5 , 6 have radially extending flow channels 7 . The transducer bodies 5 , 6 are arranged alternately with the piezoelectric stacks 4 on the tie rod 3 with an end thread. Such an arrangement is fixed and tensioned by two threaded end b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com