Plasma zero-groove cutting equipment and method

A cutting equipment, zero groove technology, applied in the direction of plasma welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as unreachable, expensive, eliminate taper, etc., achieve compact design, high application value, adjustment handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

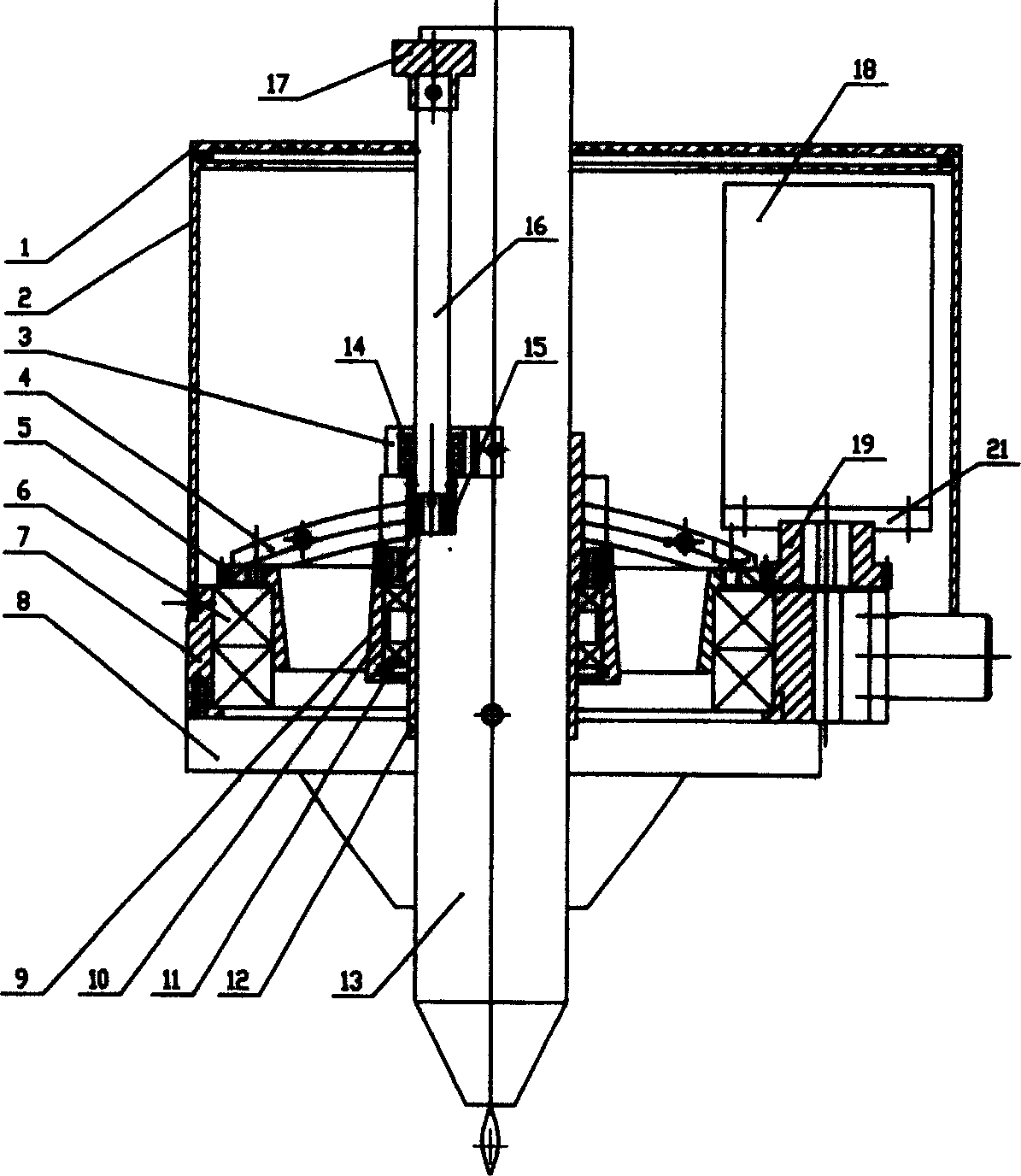

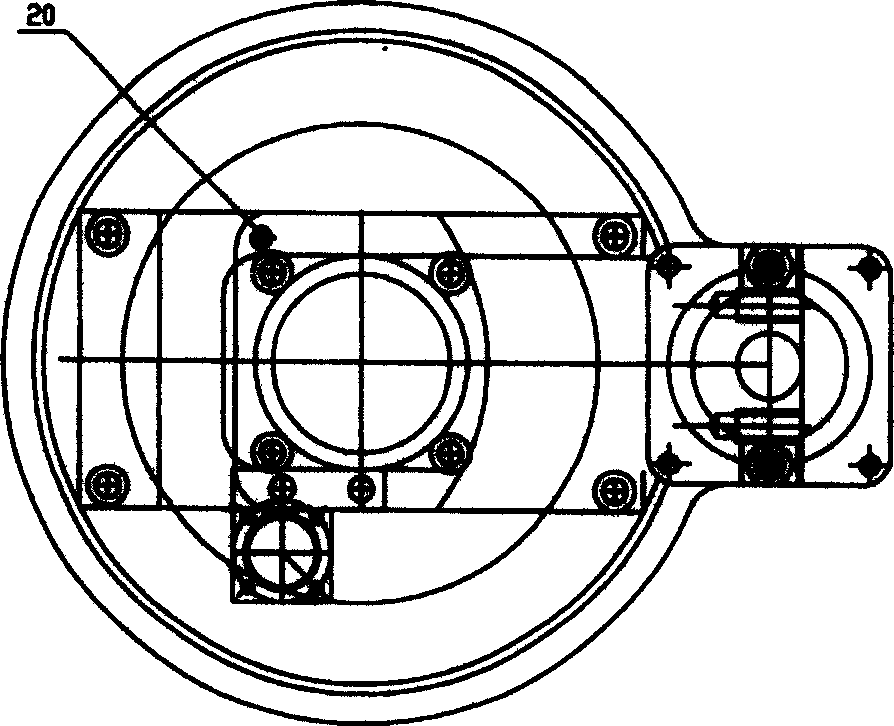

[0011] as attached figure 1 As shown, the servo motor 11 adopts Panasonic MSMA042A1G, the motor power is 400W, and 3000 revolutions per minute. Pinion, module 1, number of teeth 35. The ring gear module is 1 and the number of teeth is 160. Outer bearing 61826-2Z, 2 pcs. Inner bearing 61810-2LS, 2 pcs. Angle adjustment bearing 14 is 61800-2LS, 2 pieces. Cutting torch 13 adopts MAX200. Arch beam 4 radius outer arc R190mm. Select the thickness of the cutting steel plate to be 20mm, rotate the angle adjustment handwheel to adjust the angle, and the angle of the cutting torch is 5°. During adjustment, the cutting torch 13, the cutting torch cover 12, the inner bearing 11, the cutting torch seat 9 and the angle adjustment device slide together on the arched beam 4 around the center of the arched beam 4, no matter how much the angle is, the cutting point of the cutting torch 13 Invariant with respect to the race 5, always at the same point. On the CNC cutting machine, the ser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com