Buoyancy generating equipment

A power generation equipment and buoyancy technology, applied in hydropower, mechanical equipment, engine components, etc., can solve problems such as inability to complete automatic circulation, unreasonable design of buoys, low work efficiency, etc., to achieve small maintenance workload, good effect, and low consumption small energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

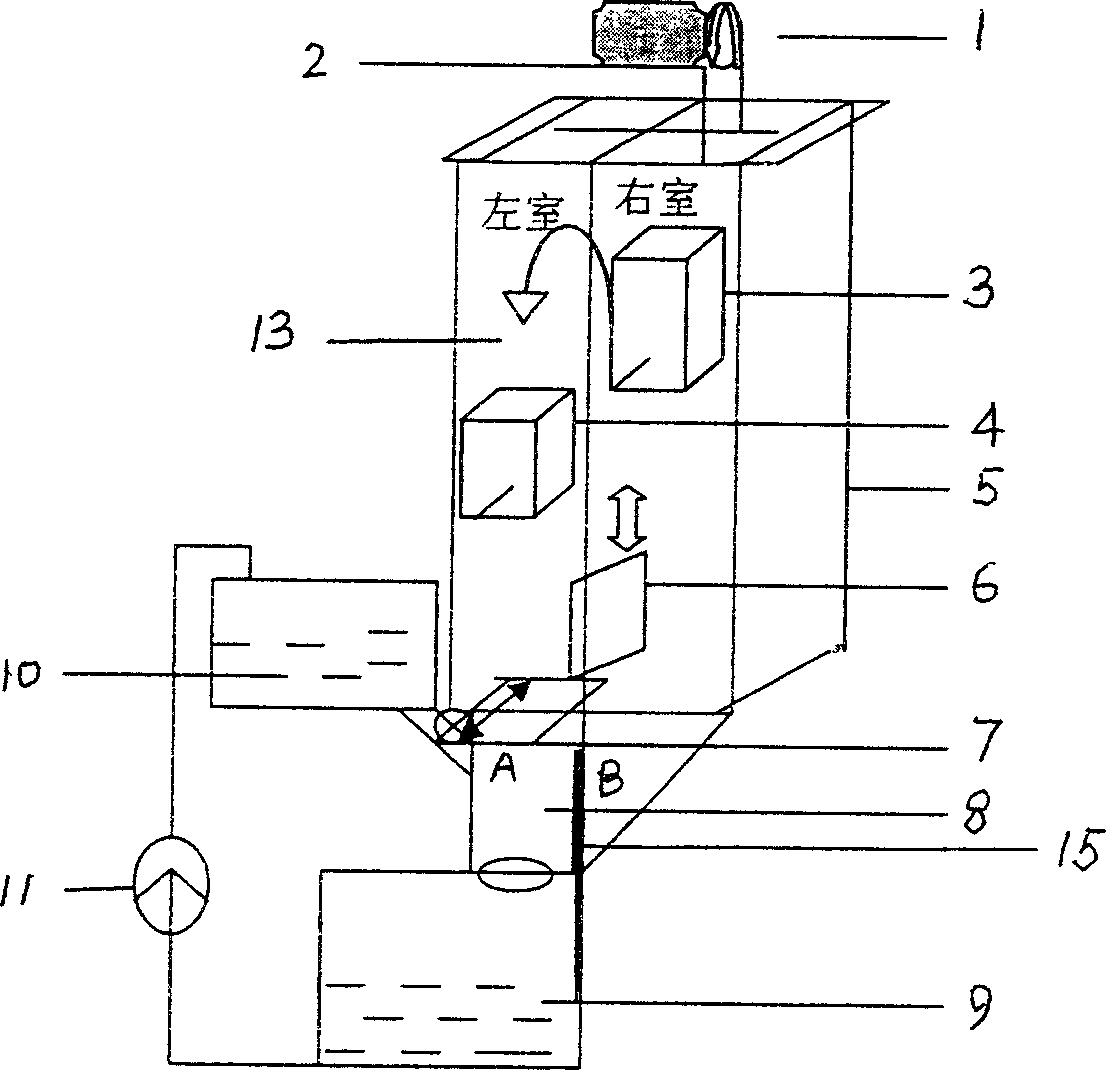

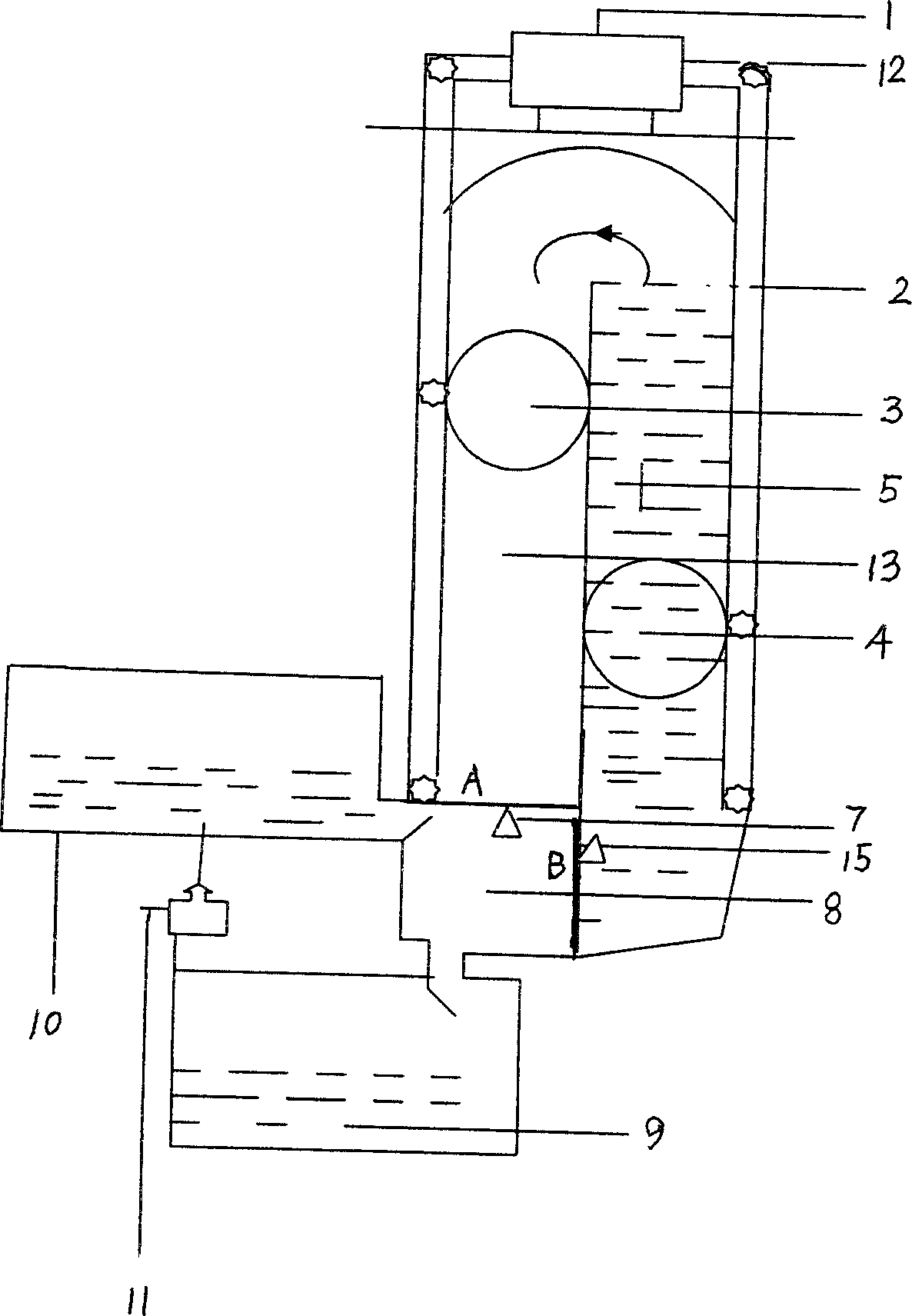

[0035] Such as figure 1 As shown, the buoyancy power generation equipment includes a high-level pool 10, a low-level pool 9, floats 3, 4, and a circulation control tank that provides work for the floats. The control tank is cylindrical, and the floater is spherical. 2. The chain drive belt 2 is connected to the generator 1. The circulation control tank is a container divided into two chambers, with a partition installed in the middle. One side of the partition is the liquid chamber 5 (right chamber), and the other side is for the free fall of the float. Chamber 13 (left chamber), the bottom of the free fall working chamber 13 has a float transfer chamber 8, the float transfer chamber 8 has a control door 7 (A) and a control door 6 (B), and the control door (A) controls the free fall chamber 13 is opened, the control door (B) controls the opening of the liquid chamber 5, and the float transfer studio 8 also has a connecting door that communicates with the high pool 10 and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com