Optical parameter absolute value measuring device and method thereof

An optical parameter and measuring instrument technology, applied in the field of analytical instruments, can solve problems such as poor flexibility, attenuation of light energy reaching the detector, instrument structure design, and complicated installation and debugging, and achieves improved photometric accuracy, easy instrument operation, and light energy. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

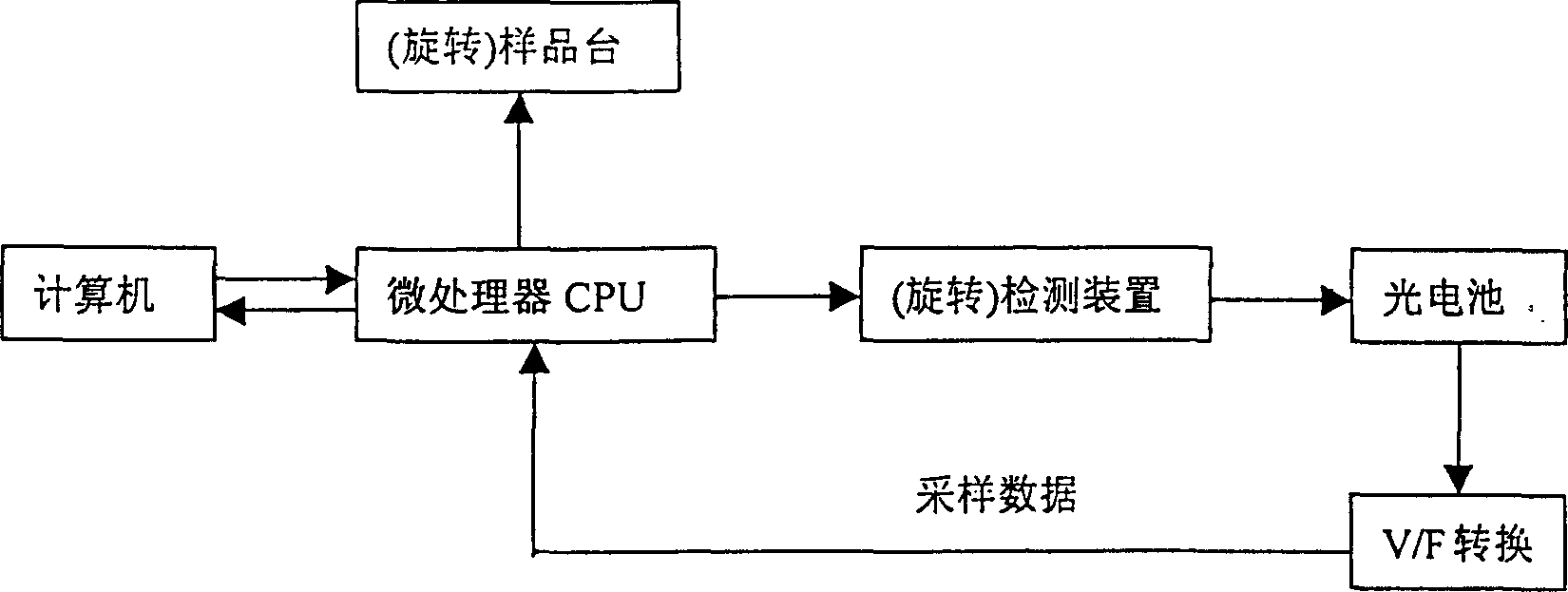

[0021] From figure 1 It can be seen that the microprocessor CPU of the present invention accepts instructions from an external computer to manipulate the rotation angles of the sample stage and the detection device to obtain the best position for sample measurement. The measurement results of the detection device are converted by photoelectricity and V / F, and then returned to the computer through the microprocessor CPU for data processing.

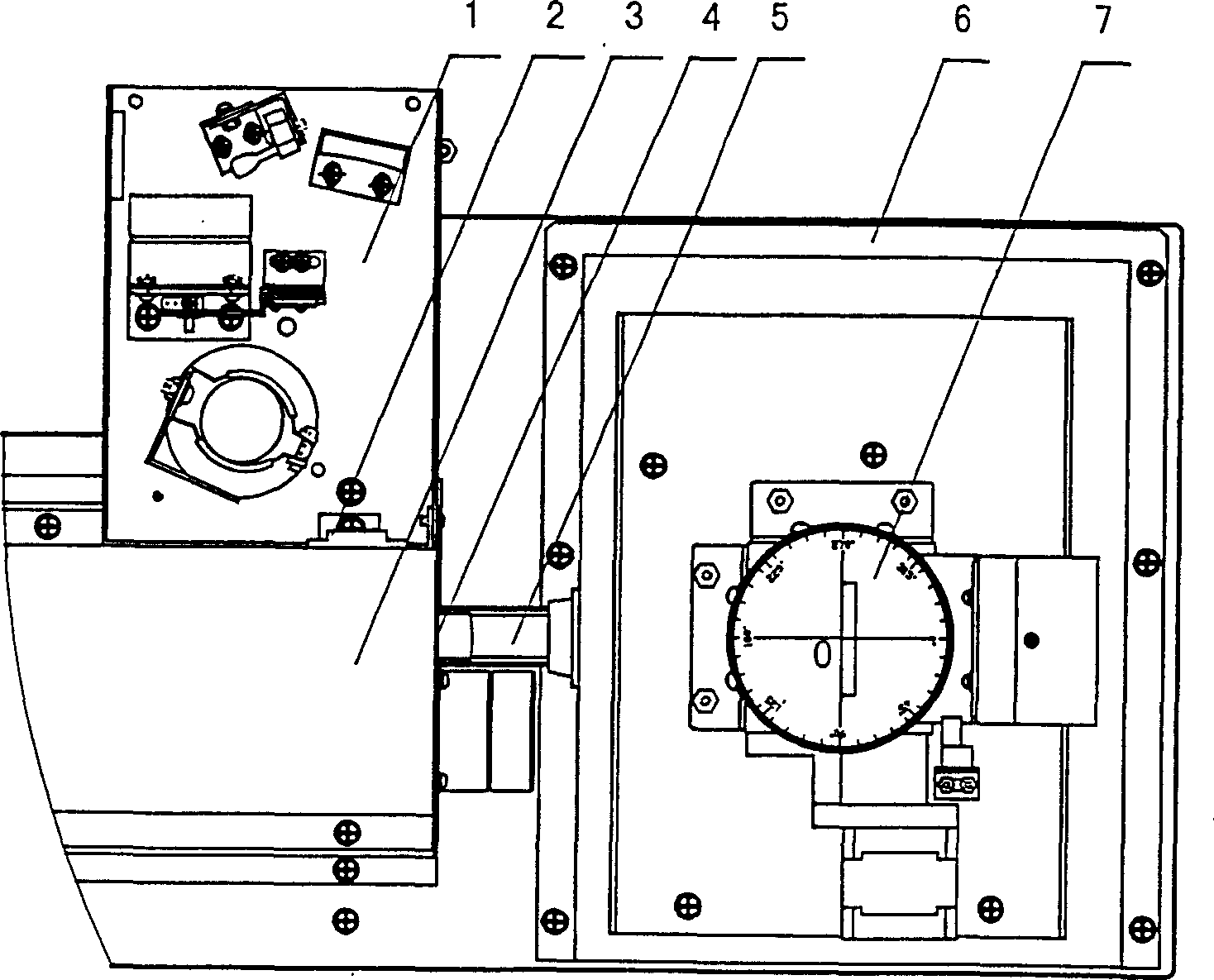

[0022] figure 2 It is a schematic diagram of the structure of the whole machine of the present invention. As shown in the figure, the composite light of the light source in the lamp chamber 1 enters the monochromator 3 through the entrance slit 2, and the monochromatic light enters the sample chamber 6 through the exit slit 4 through the lens barrel 5 , and then enter the detector 12 through the sample 11 placed on the sample stage 9 for signal processing.

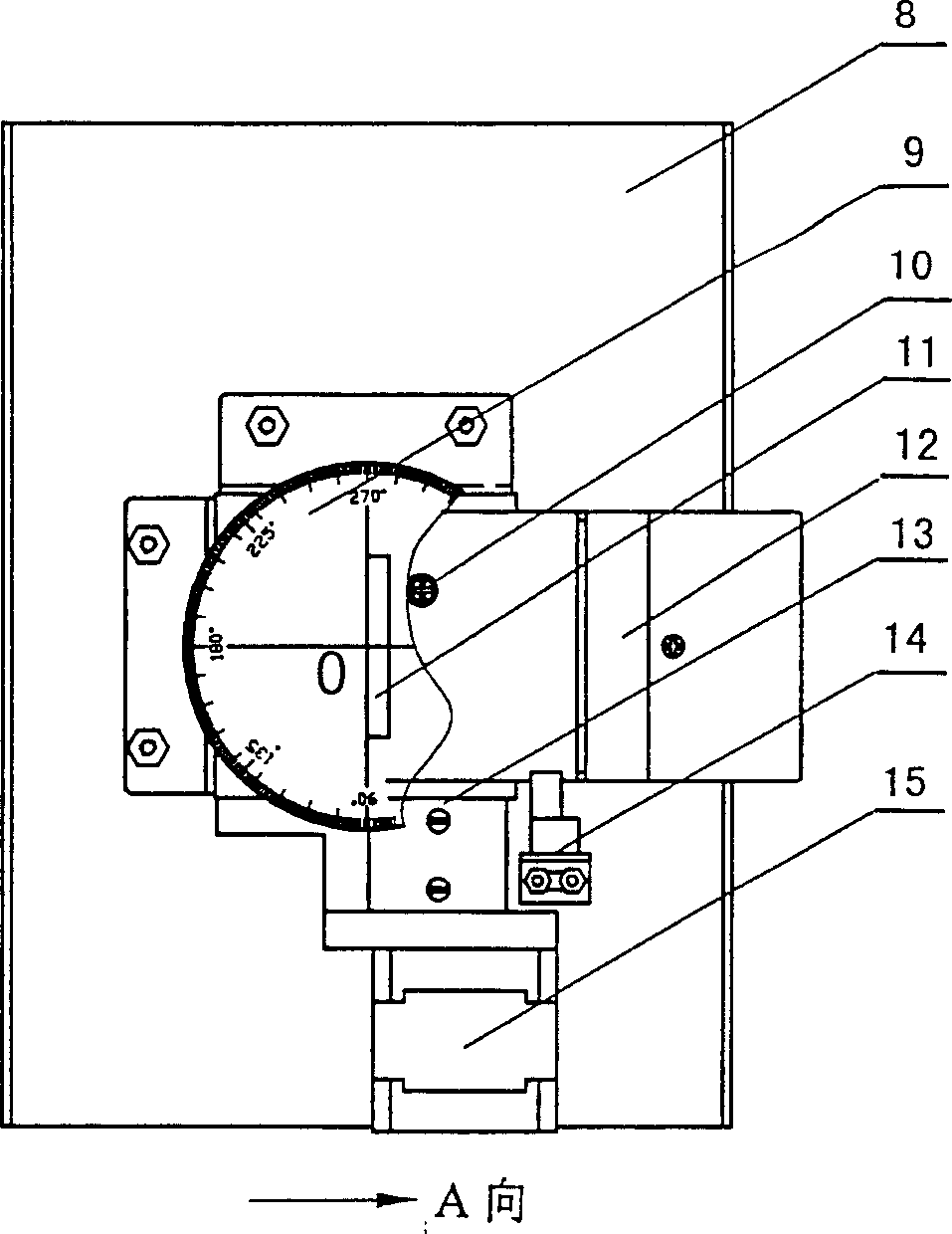

[0023] image 3 and Figure 4 It is a schematic diagram of the detection devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com