Piston pump

A piston pump and piston technology, applied in the direction of pumps, multi-cylinder pumps, pump components, etc., can solve problems such as deformation of the check valve seat, jeopardizing the reliability of the vehicle braking system, etc., and achieve an enlarged suction section and good suction characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

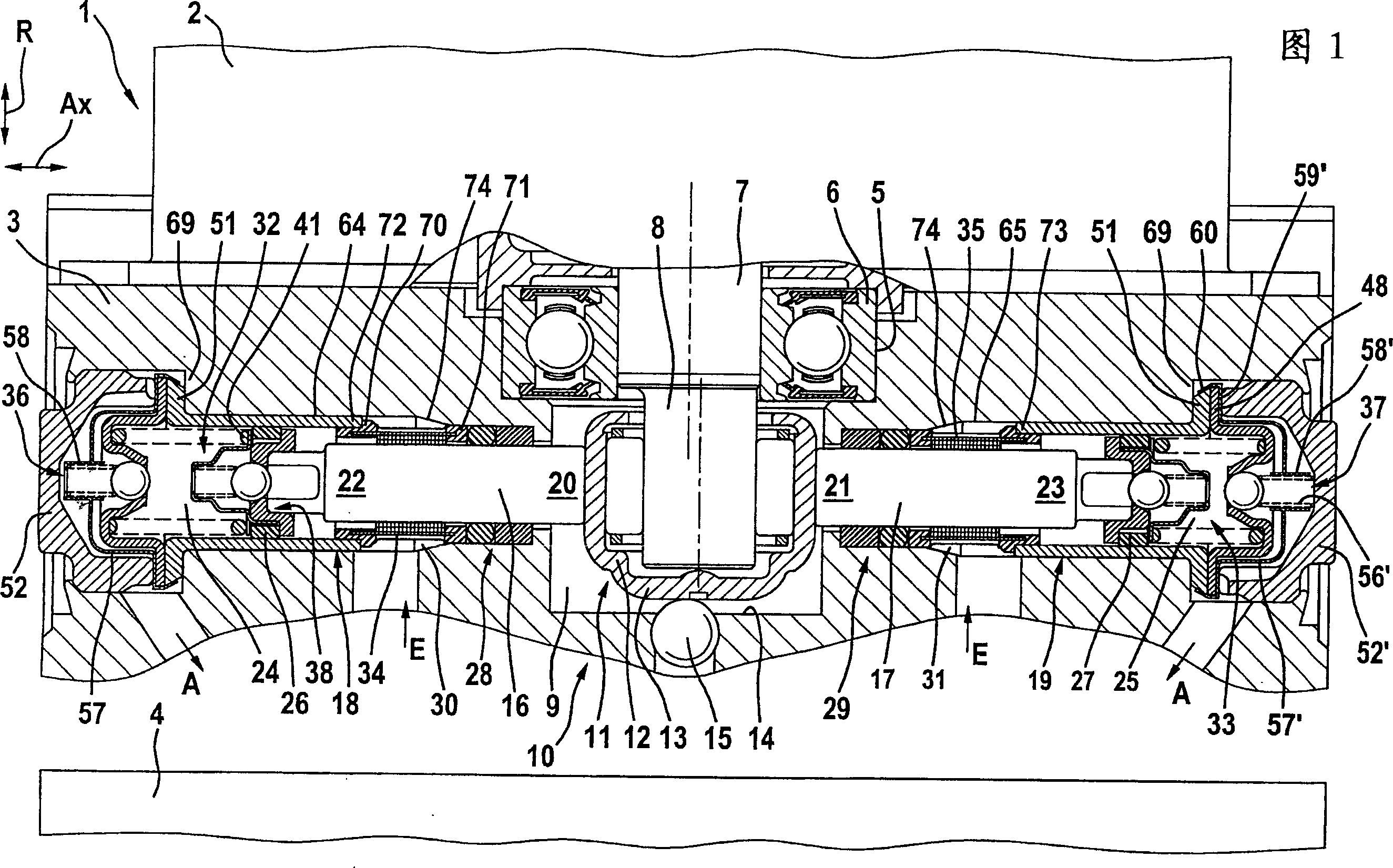

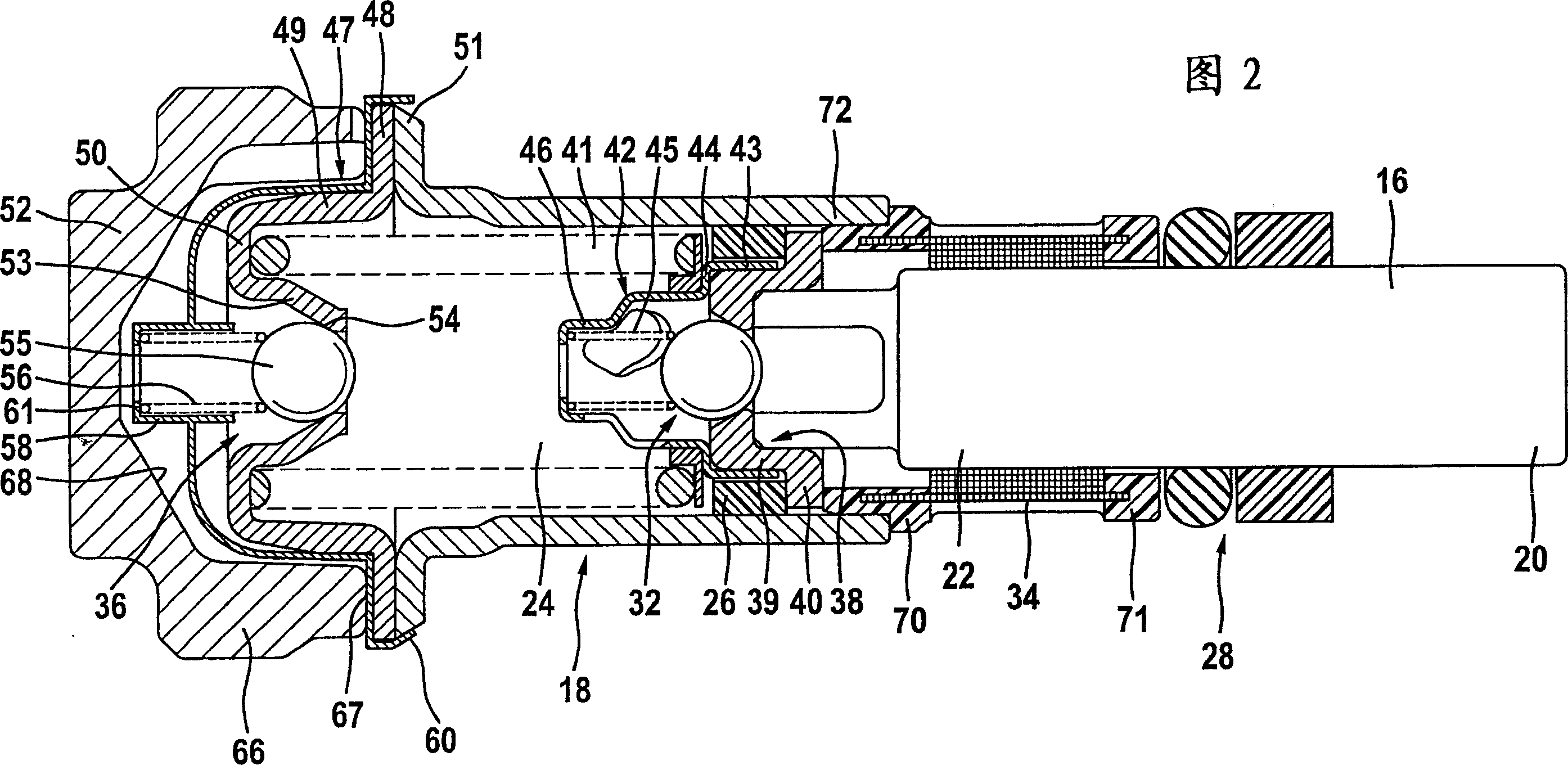

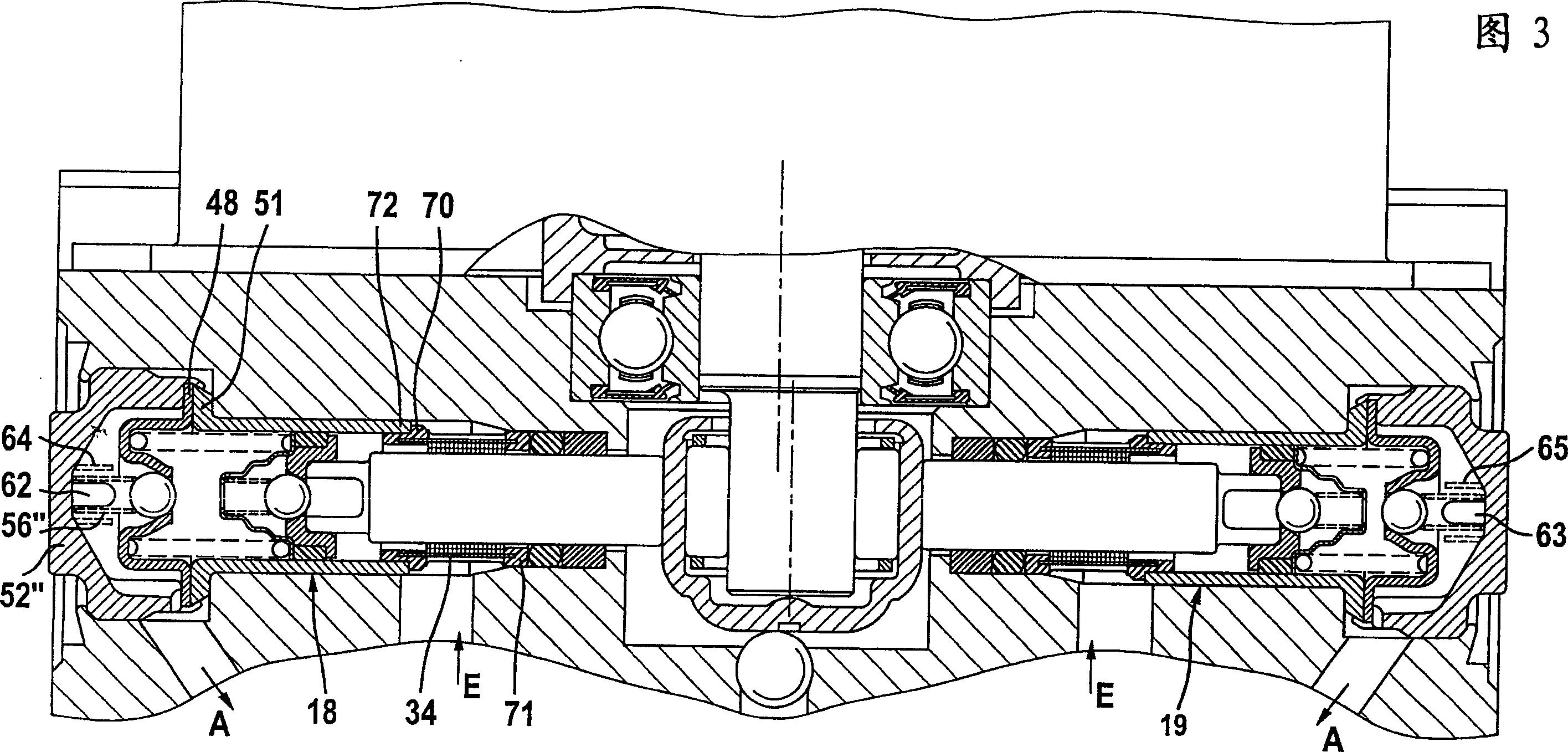

[0018] FIG. 1 shows an assembly 1 with a schematically shown drive 2, in particular an electric motor, which is flanged to a system for solenoid valves, channels, accumulator chambers or buffer chambers and Receiving part 3 of a piston pump 10 . On the opposite side of the receiving part 3 there is an electronic control unit 4 (shown only schematically). The shown assembly 1 is used in particular for slip control or driving stability control in a motor vehicle, but it can also be used for similar or different applications.

[0019] A preferably centrally located stepped bore 5 of the receiving part 3 accommodates a sealed rolling bearing 6 of a drive shaft 7 whose free end is designed as an eccentric 8 protruding into a crank chamber 9 of the stepped bore 5 . In principle, the eccentric can be ground directly on the drive shaft 7 or the motor shaft, or it can be designed as a separate component and fixed on the drive shaft. In order to prolong the operating life of the pump,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com