Method and device for producing a maintenance-free battery having a fixed electrolyte

A storage battery and electrolyte technology, applied in the direction of lead-acid battery, lead-acid battery construction, lead-acid battery electrodes, etc., can solve the problems of increased resistance of the electrolytic cell, deterioration of contact connection, adverse effects of battery power, etc., to reduce movement Sexuality and uniform heat release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

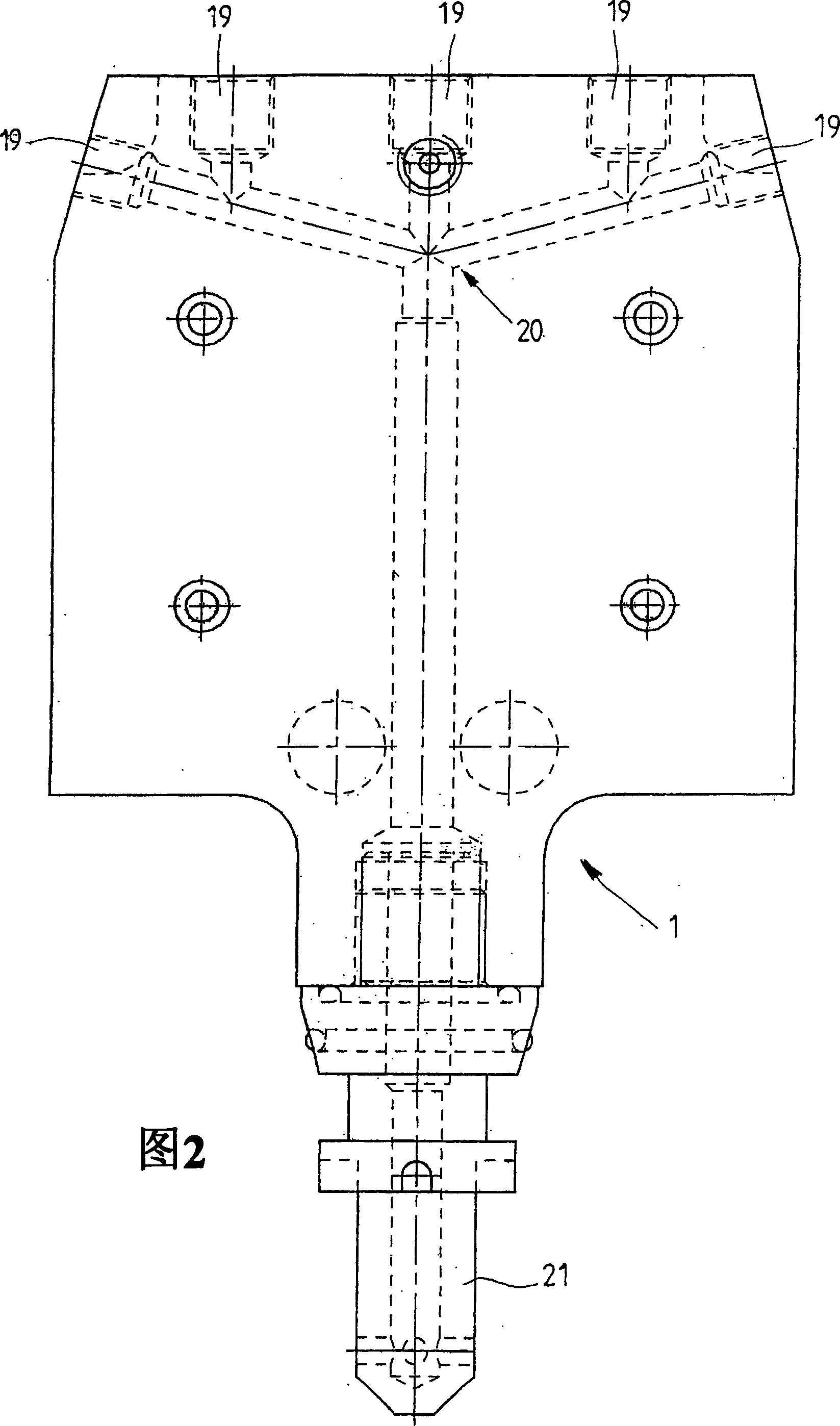

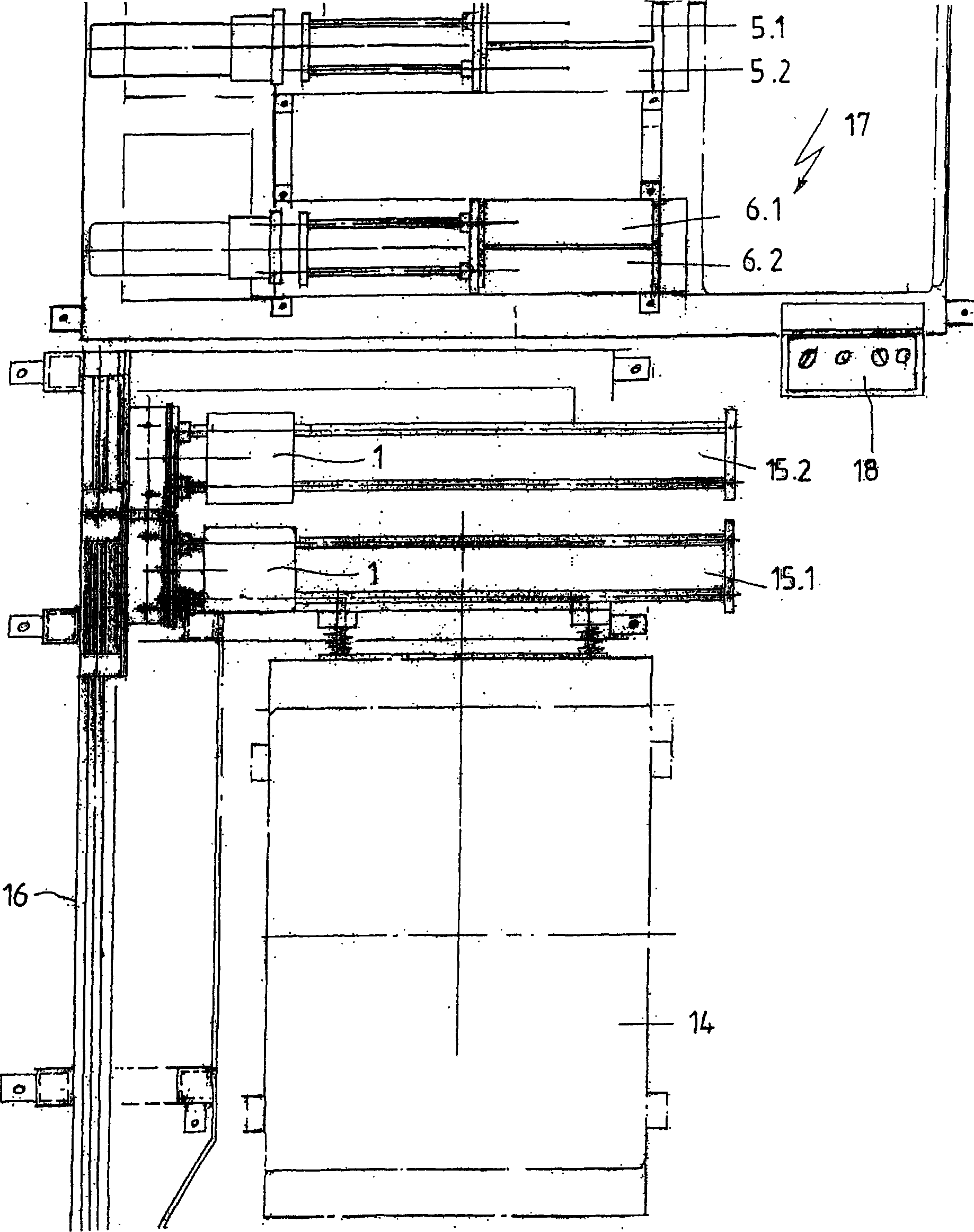

[0016] The device according to the invention for carrying out the method has, in addition to corresponding electrical connections and a power supply suitable for applying the required forming voltage, a filling head 1 with at least one each for gel, acid and flushing The injection port 19 of the medium. Furthermore, the filling head 1 has a mixing device 20 for static mixing at least the gelling agent and the acid liquid. The filling head also has a filling finger 21 which is advantageously adapted to the accumulator to be filled and which is exchangeably mounted on it for the purpose of making the filling head maneuverable. In addition, the device has flow meters for the gelling agent and the acid to be added, by means of which a precise mixing ratio can be produced as prescribed by means of a control device.

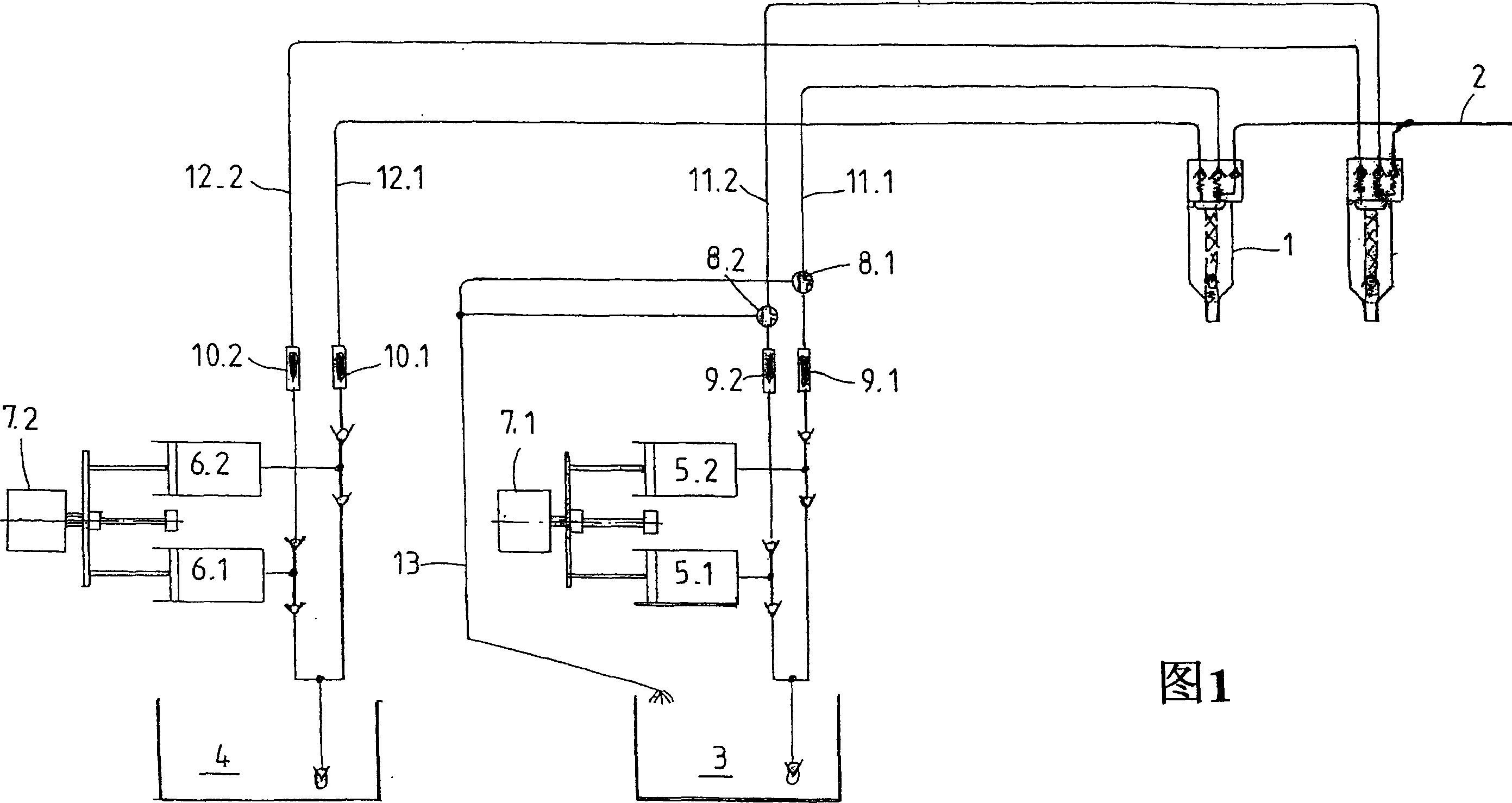

[0017] In addition, the device has an inlet line for the flushing medium 2 on the filling head, with which the residual gel in the gel delivery line 11.1 / +11.2 can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com