Device and method for weaving band shaped fibre beam fabrics

A fiber bundle and ribbon technology is applied in the field of reinforced fiber ribbon fiber bundle fabrics, which can solve the problems of large number of processes and production speed limit, and achieve the effect of less disorder and stable state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

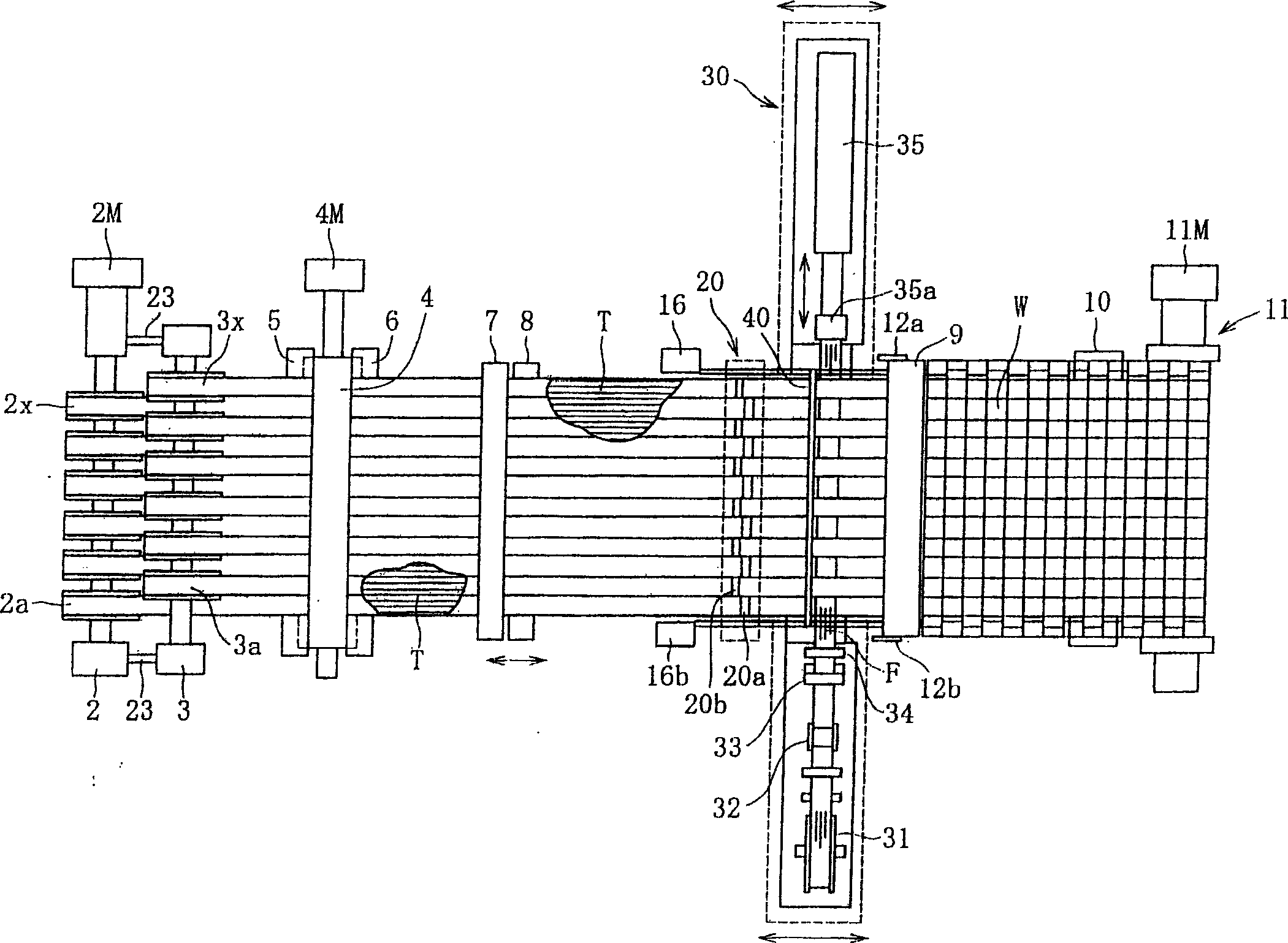

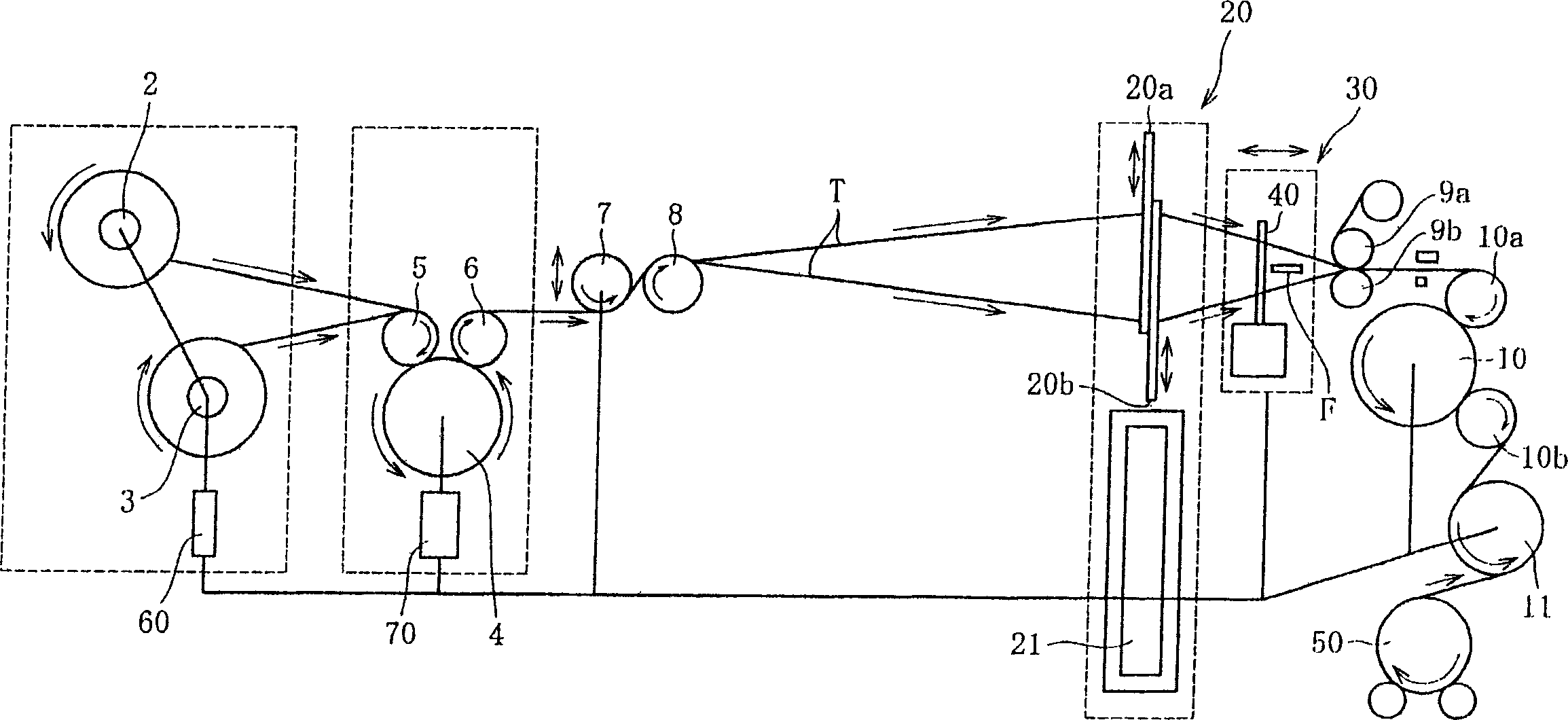

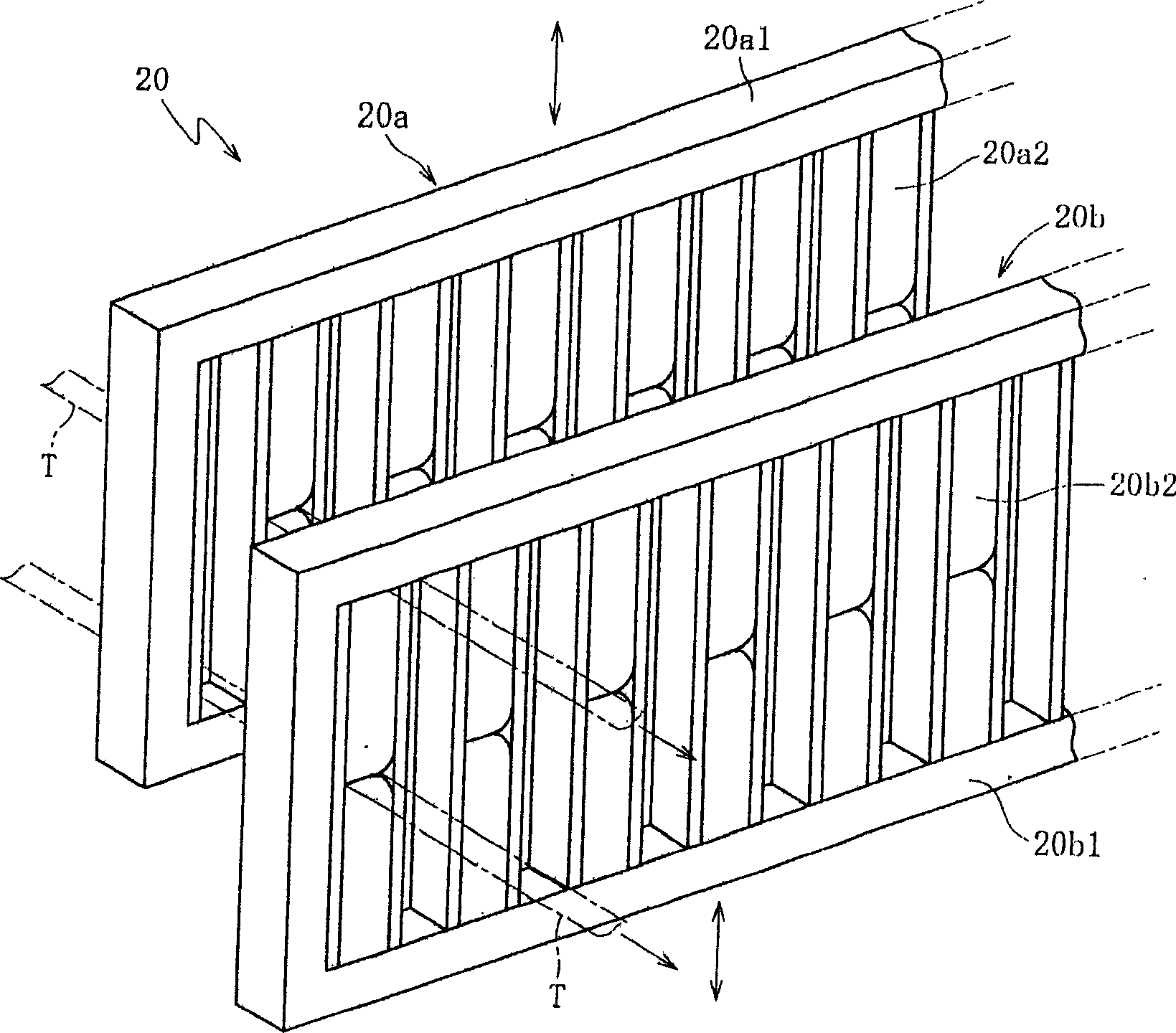

[0052] Hereinafter, the present invention will be described in detail based on the embodiments shown in the drawings.

[0053] In the weaving device of the ribbon-shaped fiber bundle fabric of the present embodiment, the ribbon-shaped fiber bundle having a substantially uniform width (expanded width / expanded thickness: 100 or more) with respect to the thickness is preliminarily processed as a ribbon-shaped fiber bundle. , for example, a carbon fiber bundle with an expanded thickness of 0.05 mm and an expanded width of 18 mm (the original fiber before the expansion process) can be used, for example, with an epoxy resin sizing agent slightly bonded to each other in parallel to 12,000 carbon fibers of 7 μm. Beam thickness is 0.1mm, width is 6.1mm).

[0054] This ribbon-shaped fiber bundle is used as the warp T and the weft F to weave a fabric to provide a fabric reinforcement for a carbon fiber-reinforced composite material.

[0055] Next, each constituent member of the weaving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com