Vertical pump for mine

A technology for vertical pumps and mines, applied in the field of vertical pumps for mines - light-duty submersible pumps for sand removal, can solve the problems of increased pressure in the cavity of the motor chamber, easy leakage and damage to the seal of the motor shaft hole, and large pressure fluctuations. Simple structure, ideal safety effect, easy to manufacture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

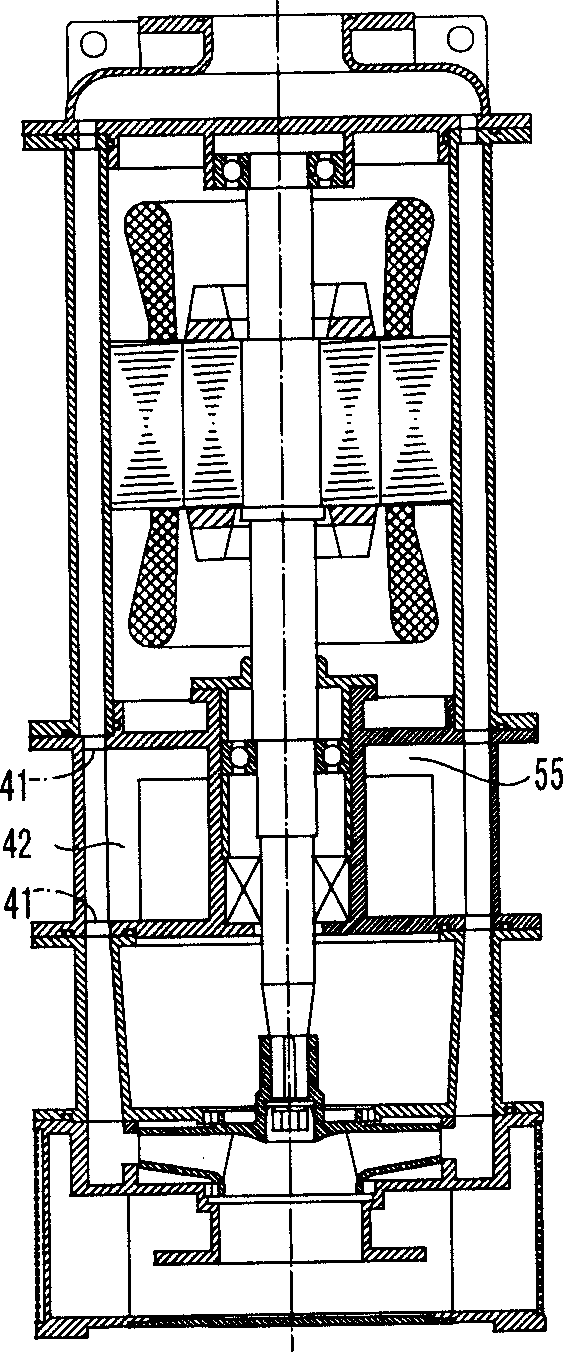

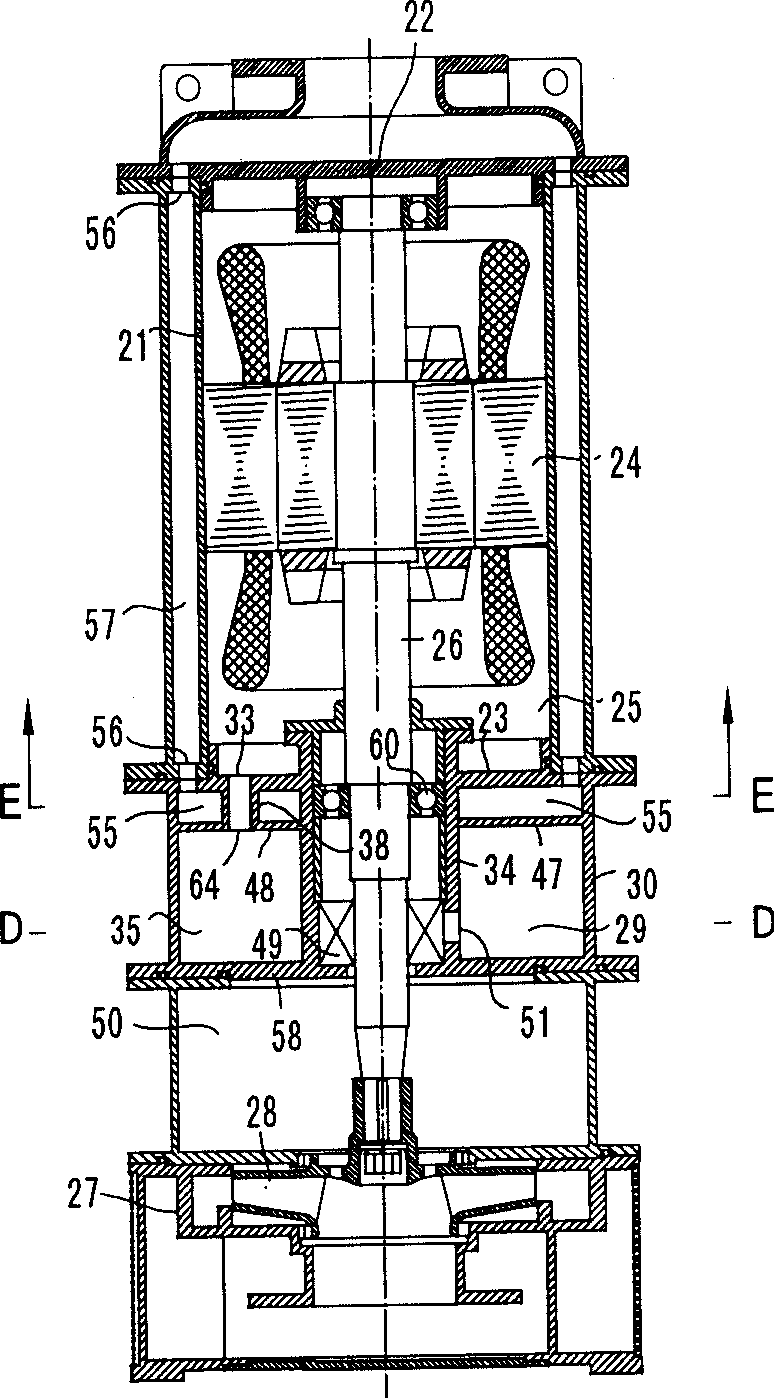

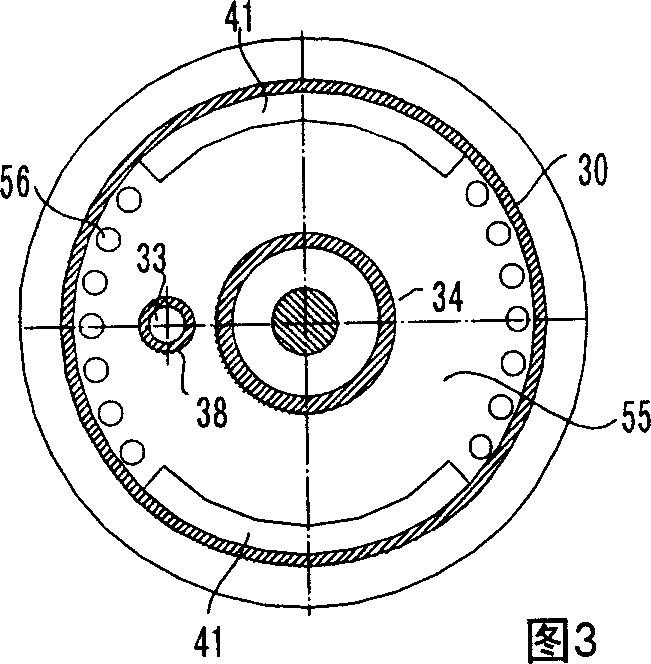

[0030] figure 1 - Fig. 4 is a set of diagrams illustrating an embodiment of the present invention. figure 2 Among them, the mine vertical pump—the light sand discharge submersible pump has a pump body 27, a pump shaft 26, an impeller 28 and a motor. Its motor has a casing 21 , an upper end cover 22 , a lower end cover 23 and a stator rotor 24 . The casing 21 together with the upper end cover 22 and the lower end cover 23 forms a closed motor chamber cavity 25 . The motor shaft hole has a mechanical seal 49. The outer oil chamber 29 outside the cylinder body 34 with the lower bearing 60 and the mechanical seal 49 inside has an oil through hole 51 communicating with the mechanical seal 49 in the cylinder body 34 body. In Fig. 4, the two sides of the two water passage chambers 42 are respectively connected with the outer oil chamber 29 and the outer space chamber 35...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com