Corrosion-proof spray irrigation pipe of Mg alloy thin wall

A magnesium alloy, sprinkler irrigation pipe technology, applied in the direction of pipes, rigid pipes, metal extrusion dies, etc., can solve the problems that have not been practically used, anti-corrosion and further optimized processing methods have not yet been disclosed, etc. Small wall thickness, easy to achieve results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

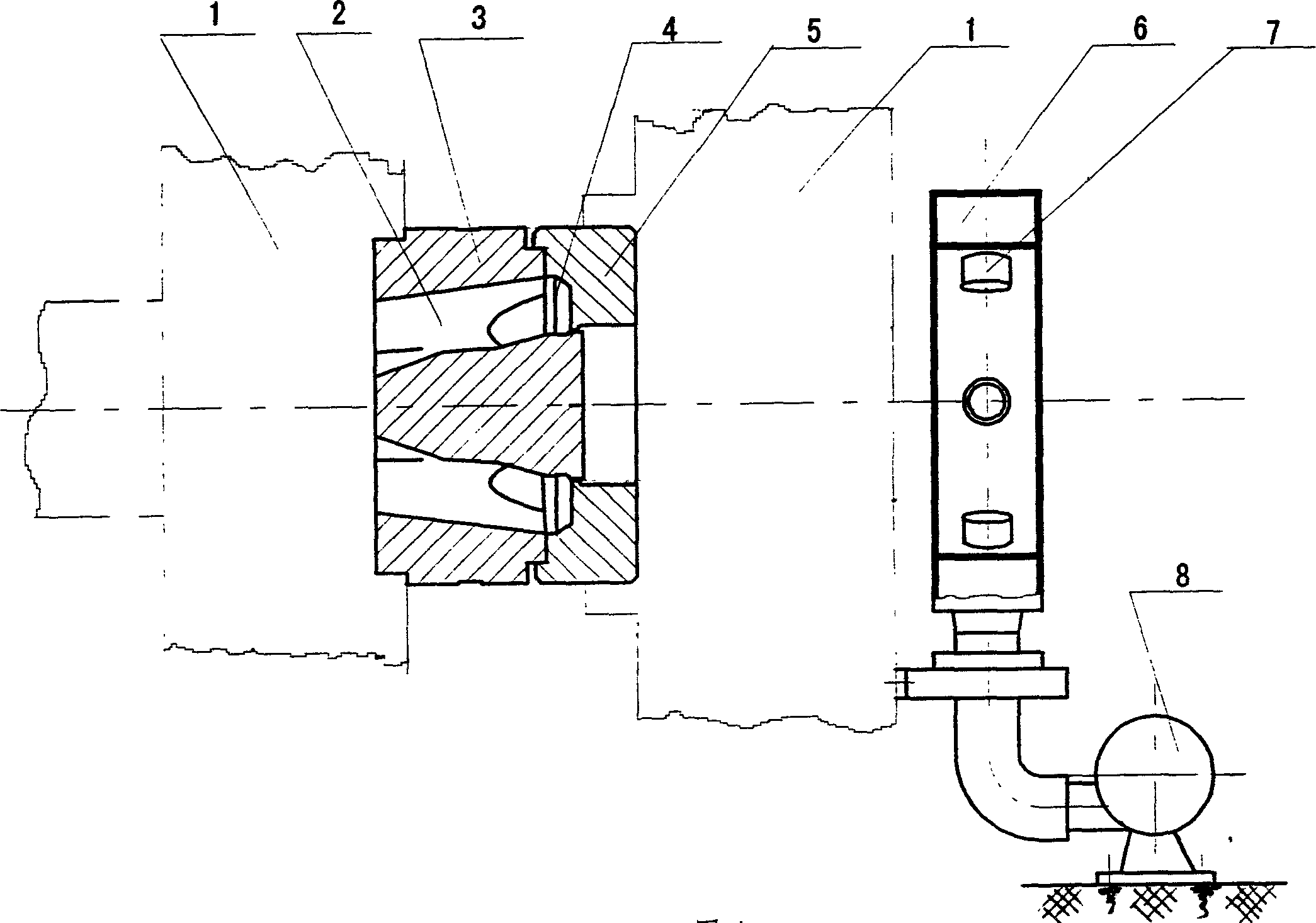

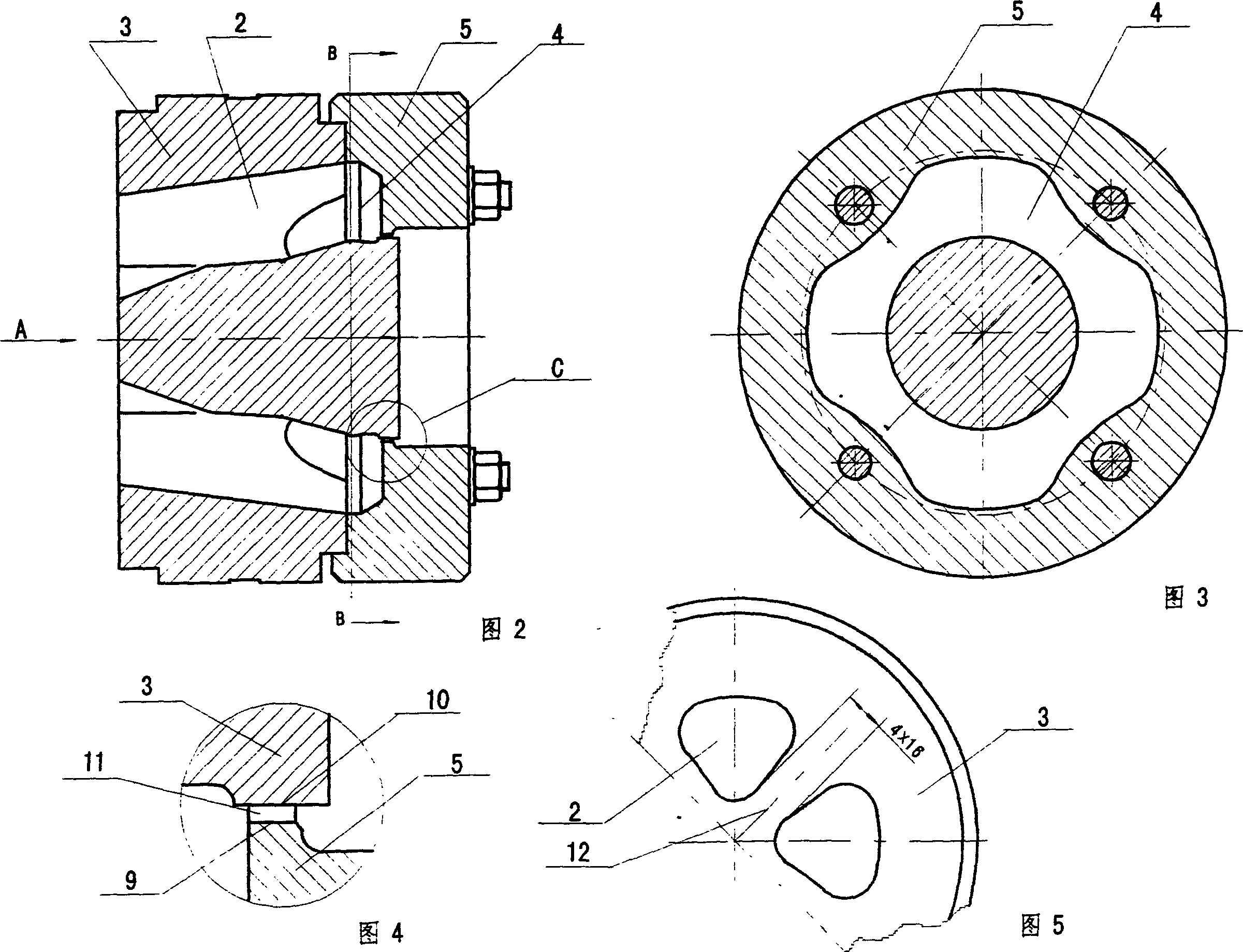

[0015] The contents represented by the part numbers marked in the attached drawings are as follows: 1. Extruder 2. Distributing hole 3. Upper die 4. Welding chamber 5. Lower die 6. Air cooling ring 7. Air outlet 8. Fan 9. Working belt of lower die 10. Working belt of upper die 11 die hole 12 shunt bridge

[0016] The first embodiment is to make a diameter of 76 mm sprinkler pipe. In this example, magnesium alloy rods with a diameter of 110 mm are selected, and an 800-ton extrusion machine is used, and the shift production is expected to be 3 tons of formed pipes. The structure and basic size of the forming die are the same as the extrusion dies for the corresponding aluminum alloy sprinkler irrigation pipes, except that the shunt bridge, welding chamber, working belt and die hole gap of the die are changed; in addition, the extrusion pipe is added to the equipment Air-cooled ring for cooling. Such as figure 1 -5, the specific content is as follows.

[0017] In this example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap