System for producing upper plates of flat fluorescent lamps

A fluorescent lamp and planar technology, applied in the field of planar fluorescent lamps, can solve problems such as thermal burst, thermal shock, glass thermal deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Reference will now be made in more detail to the preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers have been used throughout the drawings for the same or like parts.

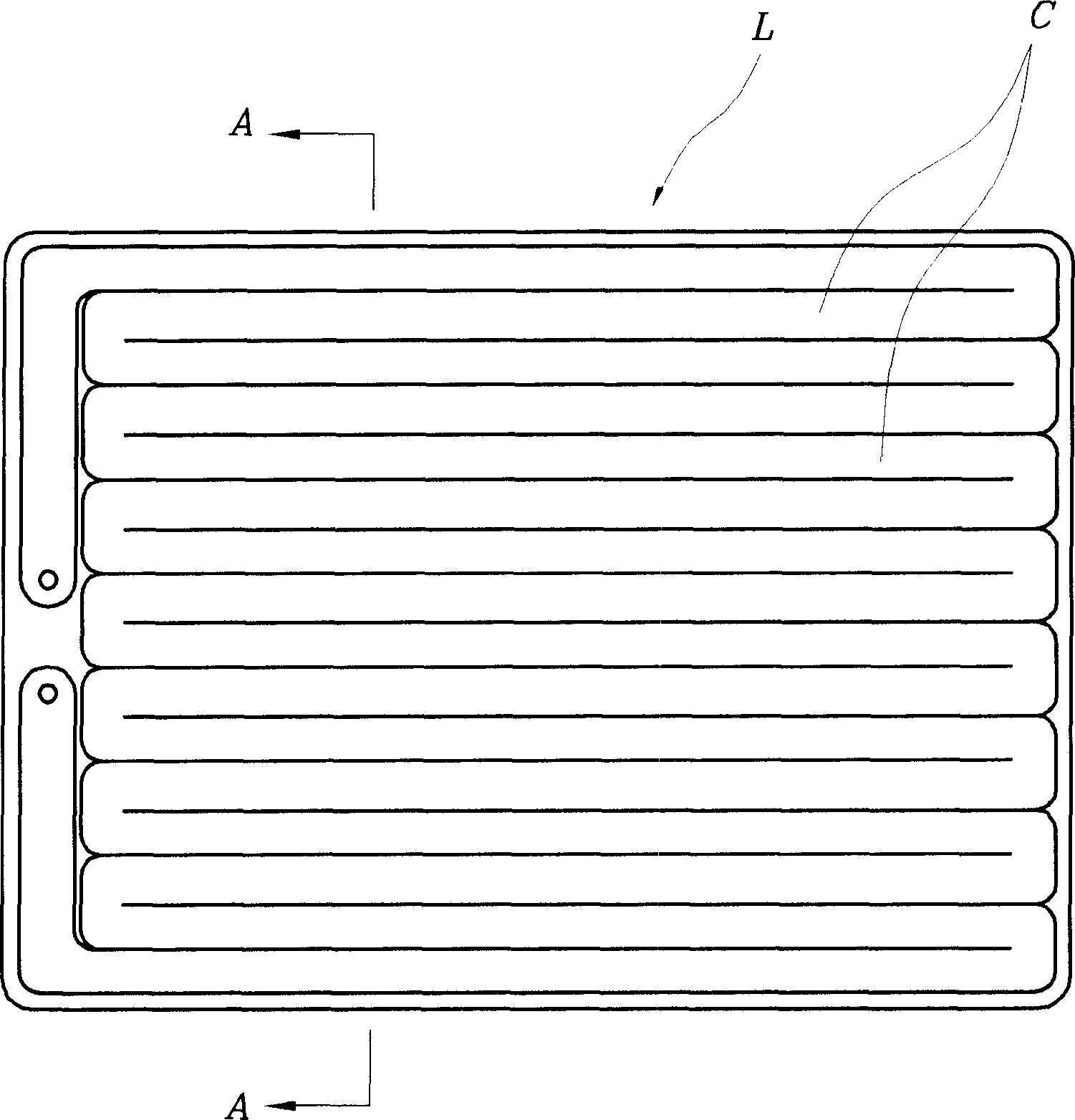

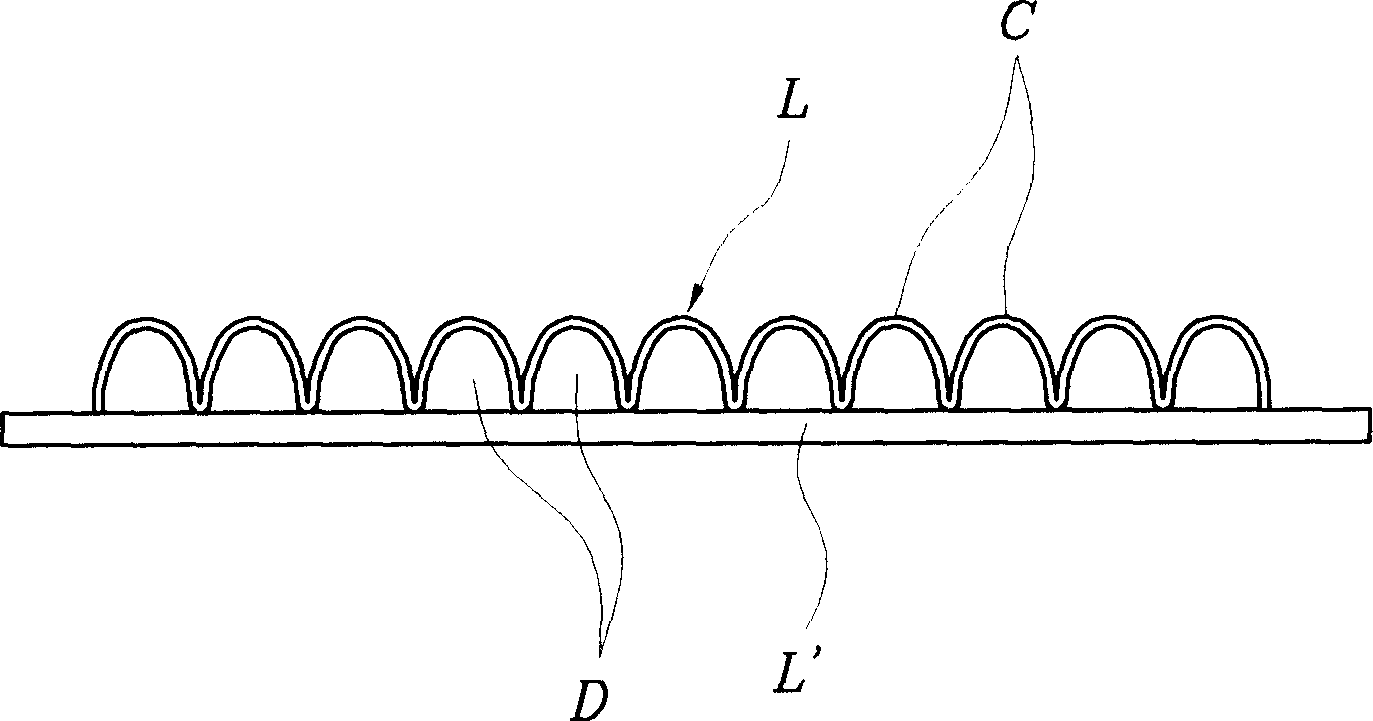

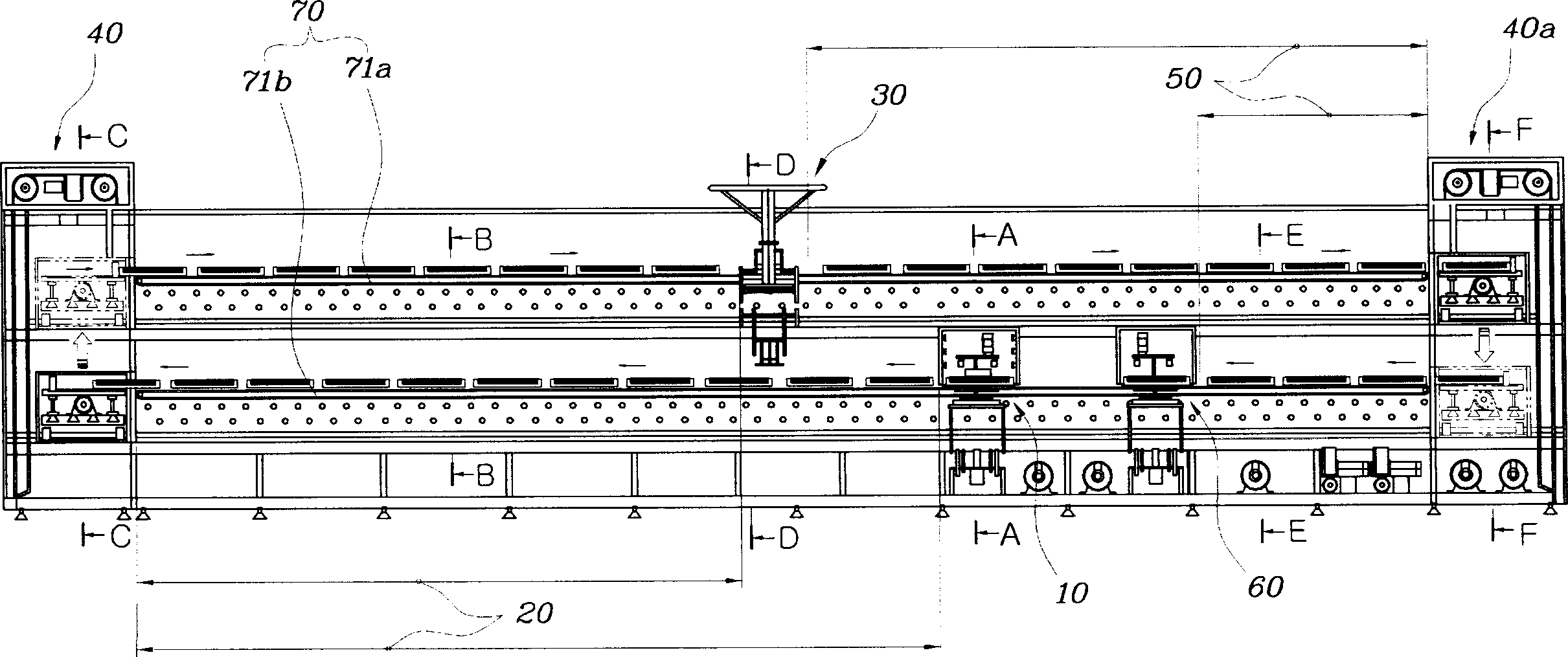

[0026] image 3 is a front view showing the structure of the FFL upper plate production system according to the present invention. As shown, the system according to the present invention includes a conveying unit 70 for real-time conveying the glass panel G and the FFL upper plate L in a desired direction. The conveyor unit 70 is configured as follows: a plurality of conveyors 71 of the same length are arranged in the conveyor unit 70, so that the conveyors 71 form a multi-layer conveyor structure, including an upper conveyor 71a and a lower conveyor 71b. The conveying unit 70 of the present invention having a multilayer conveyer structure can be implemented in the following different ways. Such as Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com