Organic electroluminescence display device and its manufacturing method

An electroluminescence and display technology, applied in the field of organic electroluminescence displays and their manufacturing, can solve the problems of increasing organic electroluminescence displays and reducing brightness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The organic electroluminescent display and its manufacturing method of the present invention will now be described in detail with reference to the accompanying drawings, and preferred embodiments will be listed as follows.

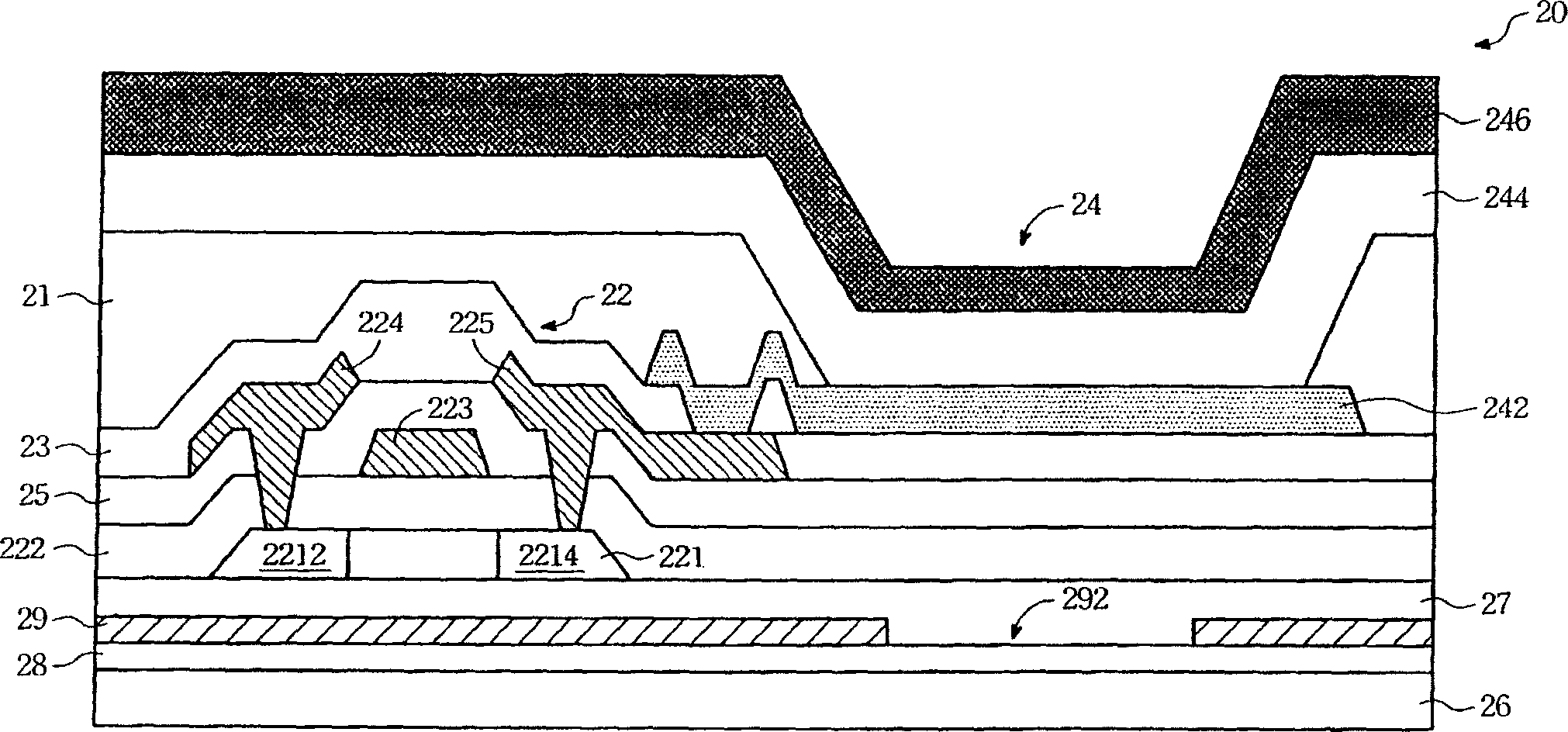

[0045] Please refer to figure 2 , which is a cross-sectional view of the organic electroluminescence display of the present invention. Each pixel structure of the organic electroluminescent display 20 includes a thin film transistor 22 and an organic light emitting diode 24 disposed on a substrate 26 . There is an anti-reflection layer 28 and a light-shielding layer 29 between the TFT 22 and the substrate 26 , but there is no light-shielding layer 29 between the OLED 24 and the substrate 26 . The anti-reflection layer 28 is directly formed on the surface of the substrate 26 , and the light-shielding layer 29 covers the anti-reflection layer 28 and has an opening 292 to expose part of the anti-reflection layer 28 . The OLED 24 is located above the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com