Light emitting device package and back light unit for liquid crystal display using the same

A technology for backlight units and components, applied to semiconductor devices of light-emitting elements, electroluminescent light sources, semiconductor devices, etc., can solve problems such as temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0029] figure 2 is a schematic perspective view of an LED assembly according to the present invention.

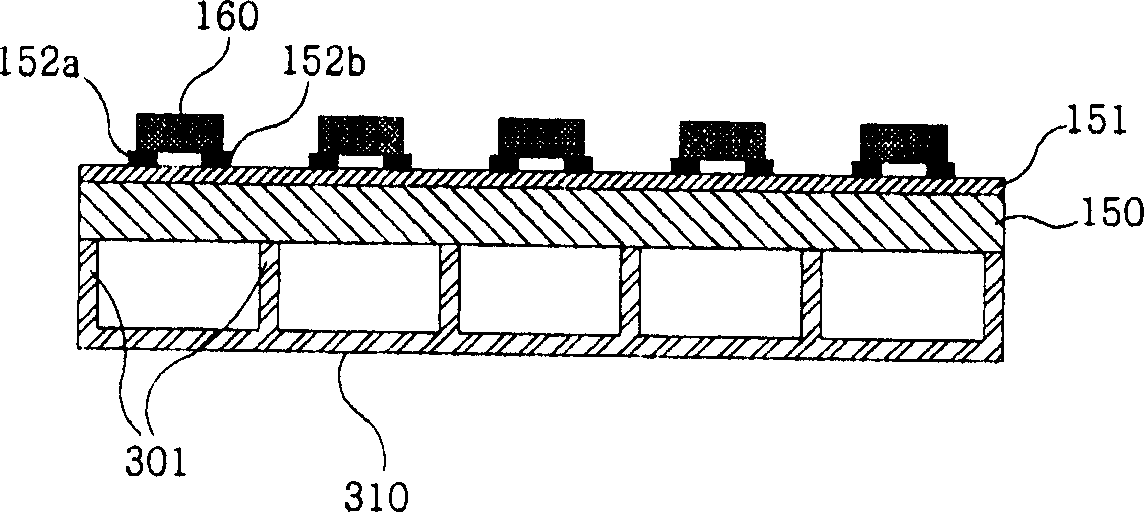

[0030] The LED assembly includes: a metal substrate (150), an insulating sheet (151) formed on the upper surface of the metal substrate (150), and a plurality of electrode wires (152a, 152b) formed on the insulating sheet (151); LEDs (160) arranged in rows and columns to the upper surface of a plurality of electrode lines (152a, 152b); a plurality of strip-shaped protrusions (301) fixed to the lower surface of the metal substrate on one surface thereof, each a predetermined distance apart; and a guide member (310) fixed to the other surface of the protrusion (301).

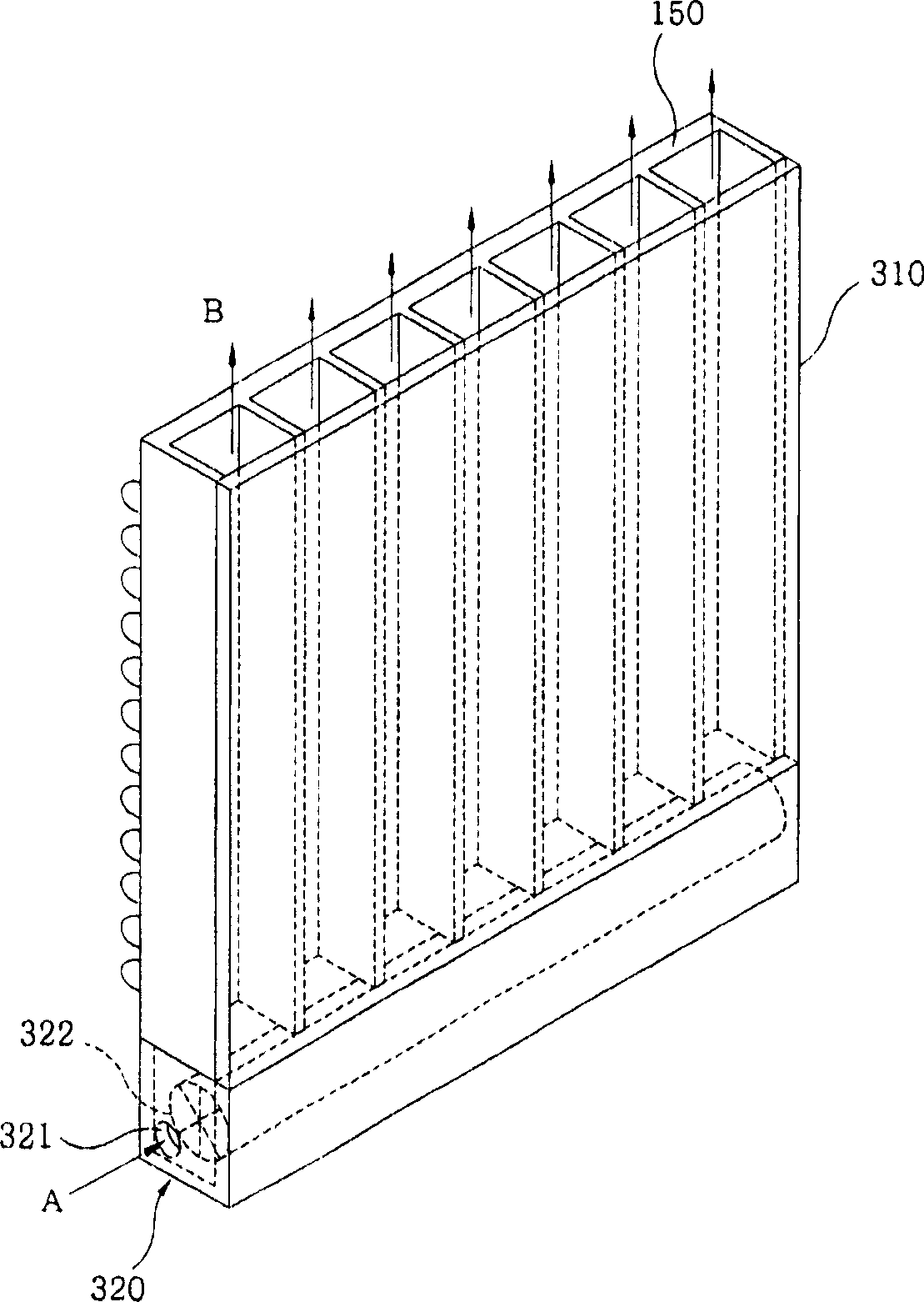

[0031] refer to image 3 , a fan (322) that absorbs air through the suction port (321) is installed in the LED assembly, and a fan housing (320) is further installed, and a fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com