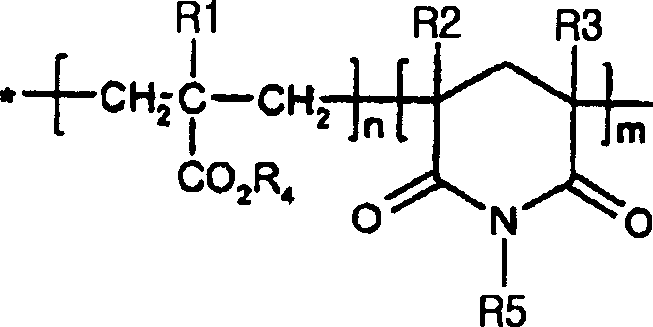

A process for preparation of polyglutarimide resin using a fluid of super critical condition

A polyglutarimide and supercritical fluid technology, applied in the production of bulk chemicals, etc., can solve problems such as difficulty in removing extractant and bubbles in extruded filaments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

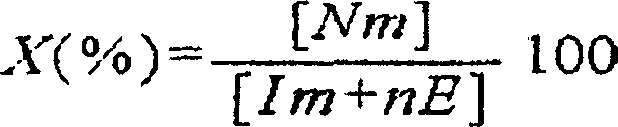

Method used

Image

Examples

Embodiment 1

[0056] Feed continuously to one inlet of a co-rotating complete mesh-type twin screw extruder having a diameter of 27 mm and a length of 1296 mm, having a weight average molecular weight of 160,000 and a glass transition temperature of 112°C ( Tg), and a methyl methacrylate / methyl acrylate copolymer (hereinafter referred to as methacrylic resin) comprising methyl methacrylate and methyl acrylate in a weight ratio of 96:4, and at a screw rotation speed of 200 rpm Next, methylamine as an imidization agent is added at 13 / 48 of the corresponding screw along the extrusion direction of the resin to carry out the imidization reaction.

[0057] The reverse combined screw is inserted in the range of 29 / 48~37 / 48 of the full length of the corresponding screw along the extrusion direction, so that the extraction area of supercritical carbon dioxide can be formed, and under the average pressure of 4000psi, the carbon dioxide can be extracted based on the An amount of 2.1% by weight of th...

Embodiment 2~4 and comparative Embodiment 2~4

[0067] Examples 2 to 4 and Comparative Examples 2 to 4 were carried out as described in Example 1 and Comparative Example 1, respectively, except that the type of imidization reagent was changed as shown in Table 2 below.

[0068] Table 2 below describes the reaction conditions, degree of reaction, glass transition temperature and residual amine content in Examples 2-4 and Comparative Examples 2-4.

[0069]

[0070] As shown in Table 2, Examples 2-4 respectively reduced the amount of residual amine compared with Comparative Examples 2-4.

Embodiment 5~11

[0072] Example 1 was repeated except that the screw rotation speed was 250 rpm and the type of imidization reagent and the added amount of carbon dioxide were changed as shown in Table 3 below.

[0073] Amine type

[0074] As shown in Table 3, the more carbon dioxide added, the more the residual amine content in the polyglutarimide was reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com