Boring device for borehole wall

A drilling device and well wall technology, applied in drilling equipment and methods, drilling equipment, earthwork drilling, etc., can solve the problems affecting oil well life, limited perforation depth, high cost, and achieve broad field application prospects, drilling The effect of fast hole speed and large hole depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

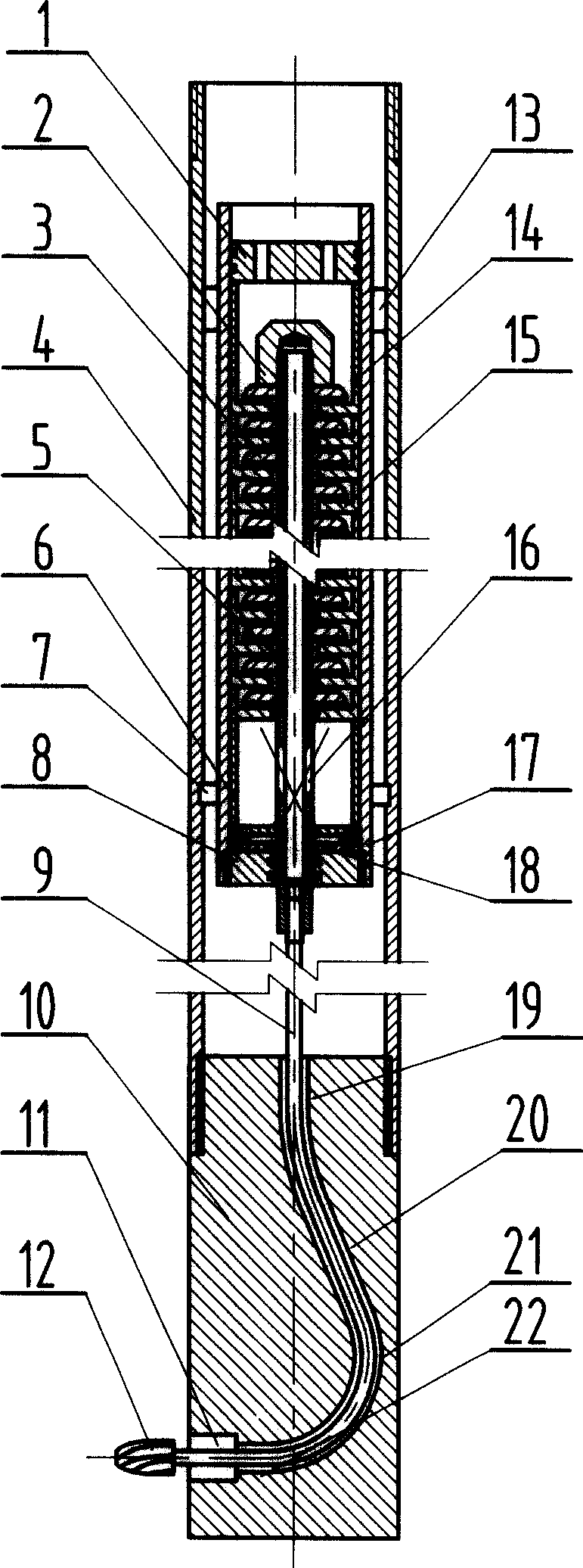

[0009] The present invention will be further described now in conjunction with the accompanying drawings of the description.

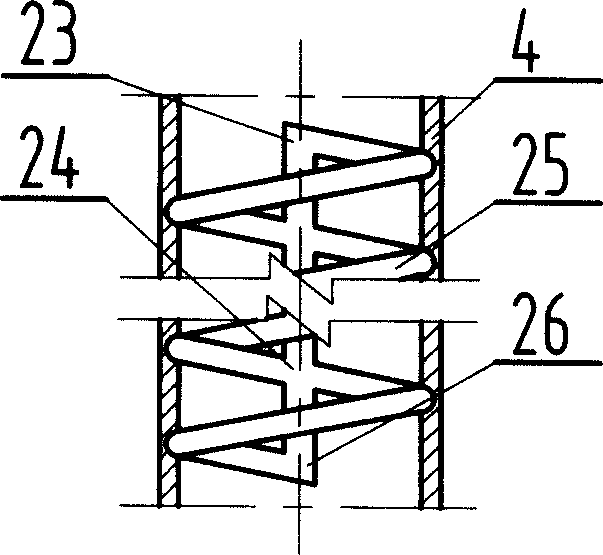

[0010] When the present invention is used for borehole drilling, the upper and lower ends of the outer cylinder [4] are respectively connected to the pipe string and the diverter [10], and the inner wall of the middle section of the outer cylinder [4] is processed with a down slideway [24] And up slideway [25], downlink slideway [24] becomes straight line, uplink slideway [25] becomes spiral shape, downlink slideway [24] and uplink slideway [25] end-to-end smooth connection, stator [15] matches Put it into the inner cylinder [17], set the rotor [3] on the hollow shaft [5], install the stator [15] and the rotor [3] at intervals, and fix the rotor [3] axially with the compression nut [2] , the upper end and the lower end of the inner cylinder [17] are respectively loaded into the upper limit sleeve [14] and the lower limit sleeve [6], and the upper end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com