Collapsible loess geology static pressure compaction pile construction method

A technology of collapsible loess and construction methods, which is applied in the field of construction engineering, can solve the problems of high noise disturbance, difficulty in verticality, and high cost of hole formation, and achieve the effects of no noise disturbance to residents, easy promotion, and fast hole formation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

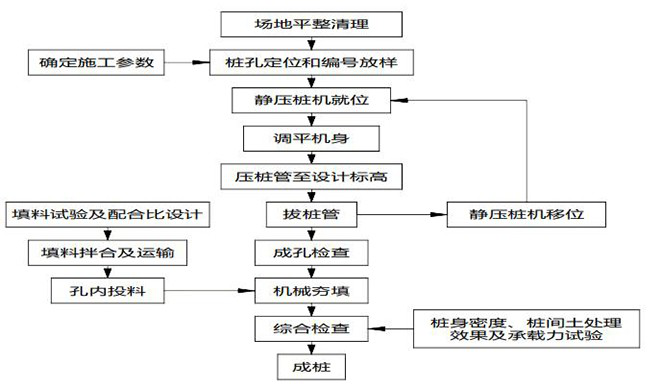

Method used

Image

Examples

Embodiment 1

[0045] The proposed site of a project in a certain place is a self-weight subsidence loess site, and plain soil compaction piles are used to treat the foundation. The absolute elevation of ±0.000 is 592.30, the elevation of the piling surface is -2.400, the pile diameter is designed to be 560mm, the effective pile length is 13.5m, and the distance between the pile centers is 1250mm, arranged in an equilateral triangle, the design elevation of the pile top is -3.000m, and the pile top is reserved The thickness of the soil layer is 600mm. Before the foundation construction, the virtual pile head and the reserved soil layer above the design elevation of the pile top should be completely excavated, and after the excavated loose layer is compacted, a 500mm thick 1:6 cement-soil cushion should be made, and the compaction The coefficient shall not be less than 0.97. The bottom of the hole should be compacted before filling. The filling in the hole should be backfilled and tamped la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com