Valve oil supplement method for series connection cylinders and apparatus therefor

A technology of connecting oil cylinders and replenishing oil, which is used in fluid pressure actuating devices, servo meter circuits, fluid pressure actuating system components, etc. problems, to achieve the effect of reducing production cost and processing difficulty, simple structure, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

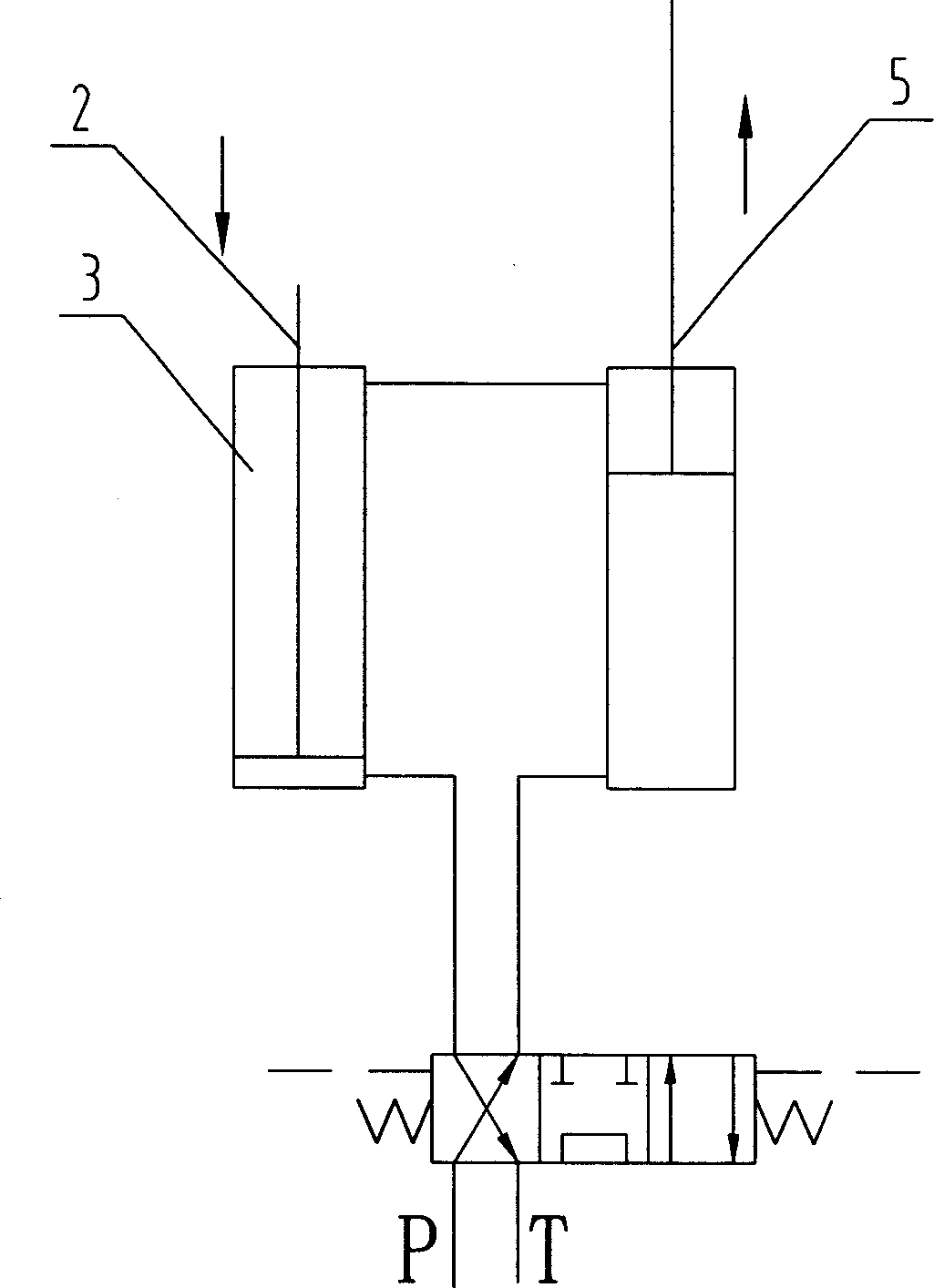

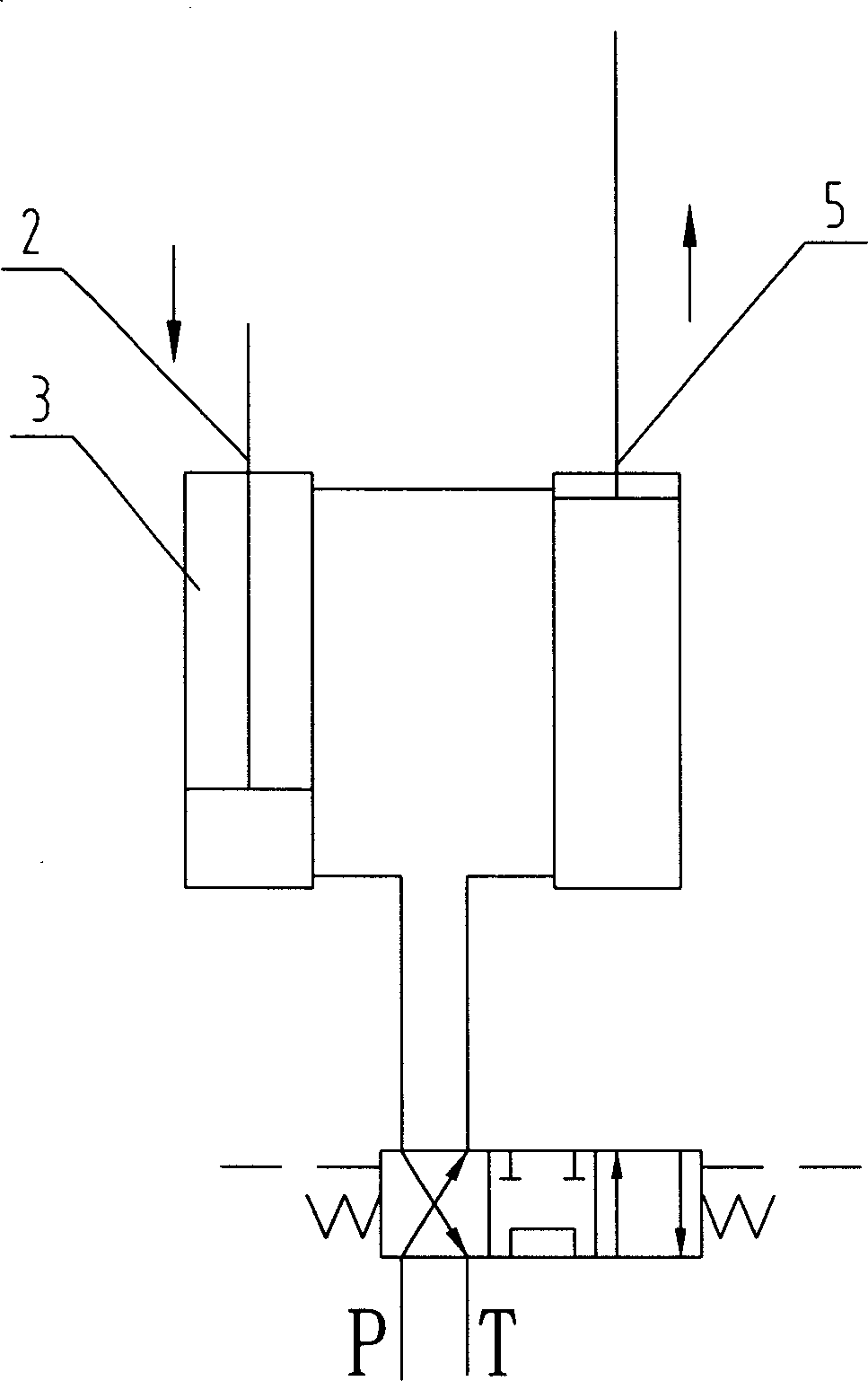

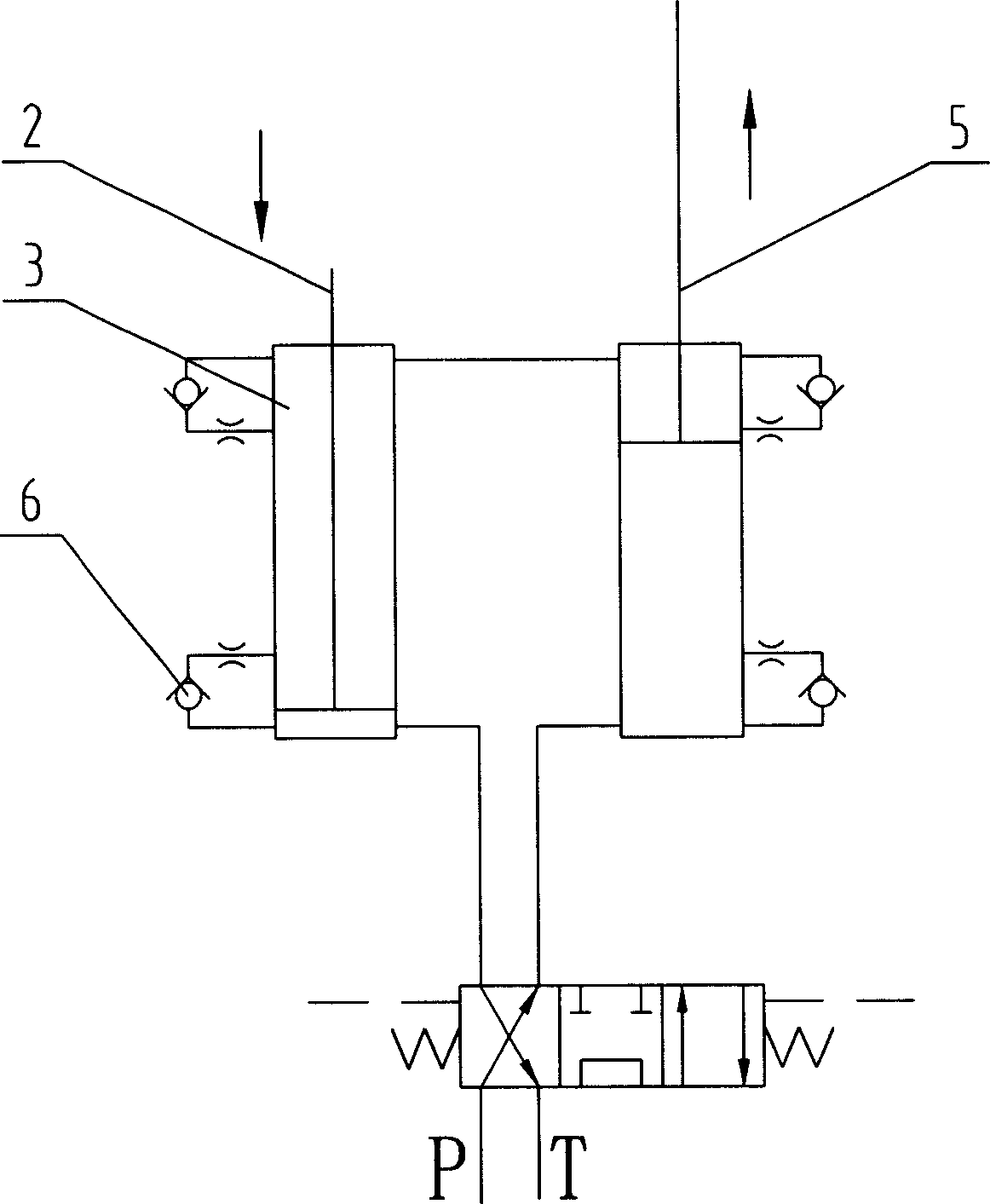

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] A method for replenishing oil to a valve of a series oil cylinder of the present invention, that is, at first respectively check whether the two piston rods (left piston rod 2 and right piston rod 5) of the series oil cylinder reach the normal forward position and the normal retraction position when working. Position detection, the detected position information is transmitted to the controller 7, the controller 7 judges according to the position signal and controls the solenoid valve 4 communicated with the communication chamber 3 of the series oil cylinder, and the communication chamber 3 of the series oil cylinder is controlled by the solenoid valve 4 Fill or drain oil. In the process of judging the position signal, when it is judged that the forward piston rod of the tandem oil cylinder has reached the normal forward position, but the retracted pist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com