Suction filter, turbo compressor, and method of packaging the compressor

A turbo compressor and filter technology, applied in chemical instruments and methods, separation methods, dispersed particle filtration, etc., can solve problems such as increased pressure loss, no introduction of three built-in coolers, performance degradation, etc., and achieves easy assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, embodiments of the suction filter of the present invention will be described with reference to the drawings.

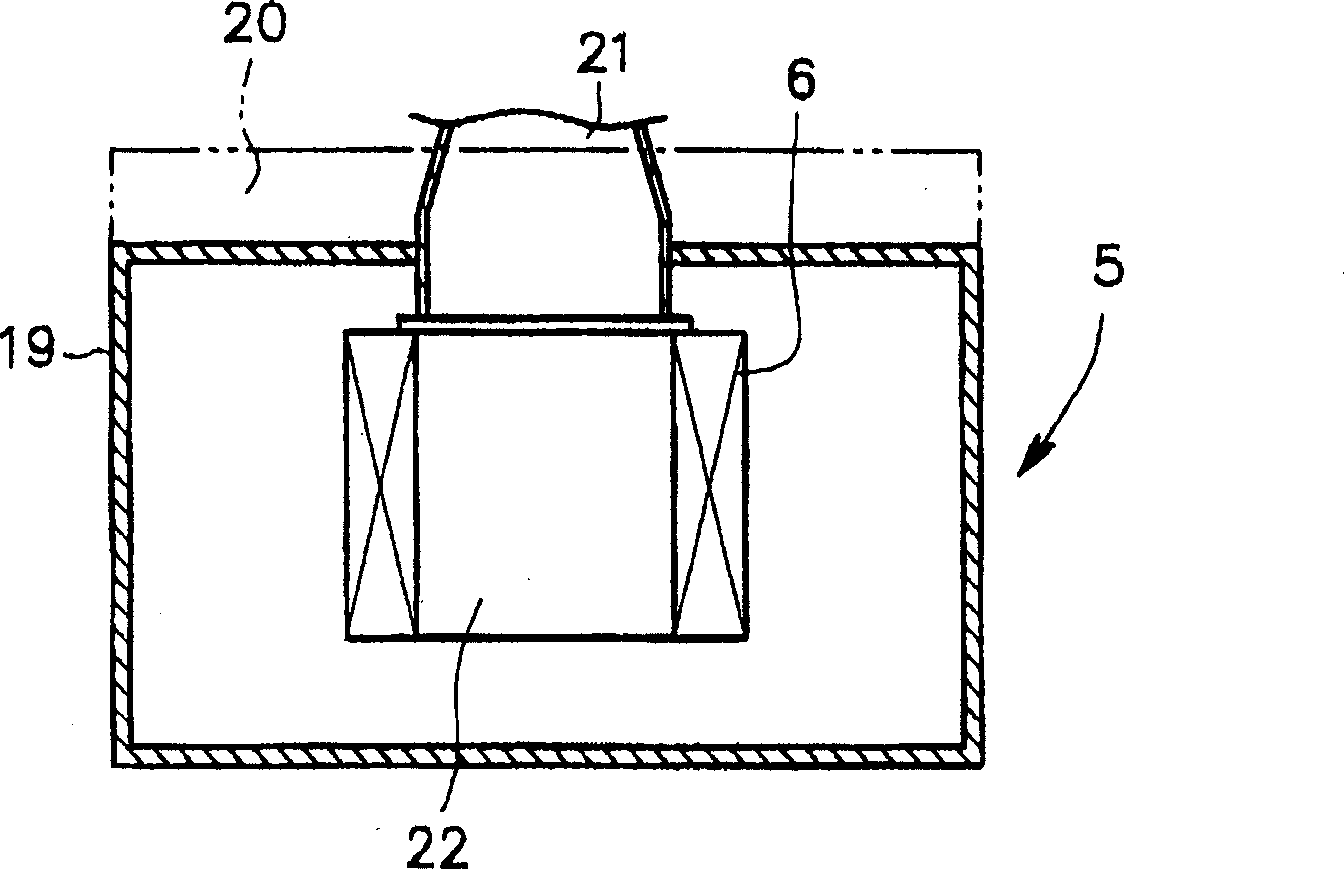

[0046] Figure 4 and Figure 5 It is a diagram showing an embodiment of the suction filter of the present invention. In the central part of the casing 19 having the suction part 20 and the discharge part 21, a chamber 23 with a closed structure having a predetermined thickness and height is provided, and the chamber An opening 24 communicating with the discharge portion 21 is provided on one side in the front-rear direction of the chamber 23 , and four openings 25 are provided on both left and right side surfaces in the thickness direction of the chamber 23 . On the outer surface of each opening 25, a small-diameter filter element mounting part 26 that is cylindrical and has an opening in the circumferential direction is installed in a horizontal state in the left-right direction. The filter element 27 of the small diameter of cylindrical shape c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com