Vertically aligned liquid crystal display using polynorbornene based polymer film

A liquid crystal display, vertical alignment technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of light leakage, incomplete viewing angle compensation of VA-LCDs, etc., and achieve good durability, low moisture absorption rate, and good adhesive strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

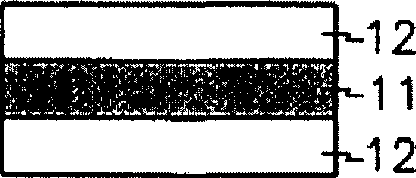

[0198] Such as image 3 structure, a vertical alignment type liquid crystal display (VA-LCD) including a polynorbornene-based polymer film serving as both a protective film of an upper polarizing plate and a negative C plate was fabricated. exist image 3 Among them, the reference symbol a is the absorption axis of the polarizing plate, and the reference symbol b is the slow axis of the A plate.

[0199] The VA panel includes a VA cell with a 3 μm gap and a pretilt of 89 degrees, filled with a liquid crystal having a negative dielectric anisotropy of Δε=−4.9 and a birefringence of Δn=0.099. Thickness retardation value of VA panel (R VA (550nm)) is 297nm.

[0200] The lower polarizing plate consists from bottom to top: an outer protective film made of TAC polymer, a polarizing film formed by dyeing a polyvinyl alcohol (PVA) film with iodine followed by stretching, an inner protective film made of TAC polymer , and A-plate membrane made of polycarbonate. At this time, the t...

Embodiment 2

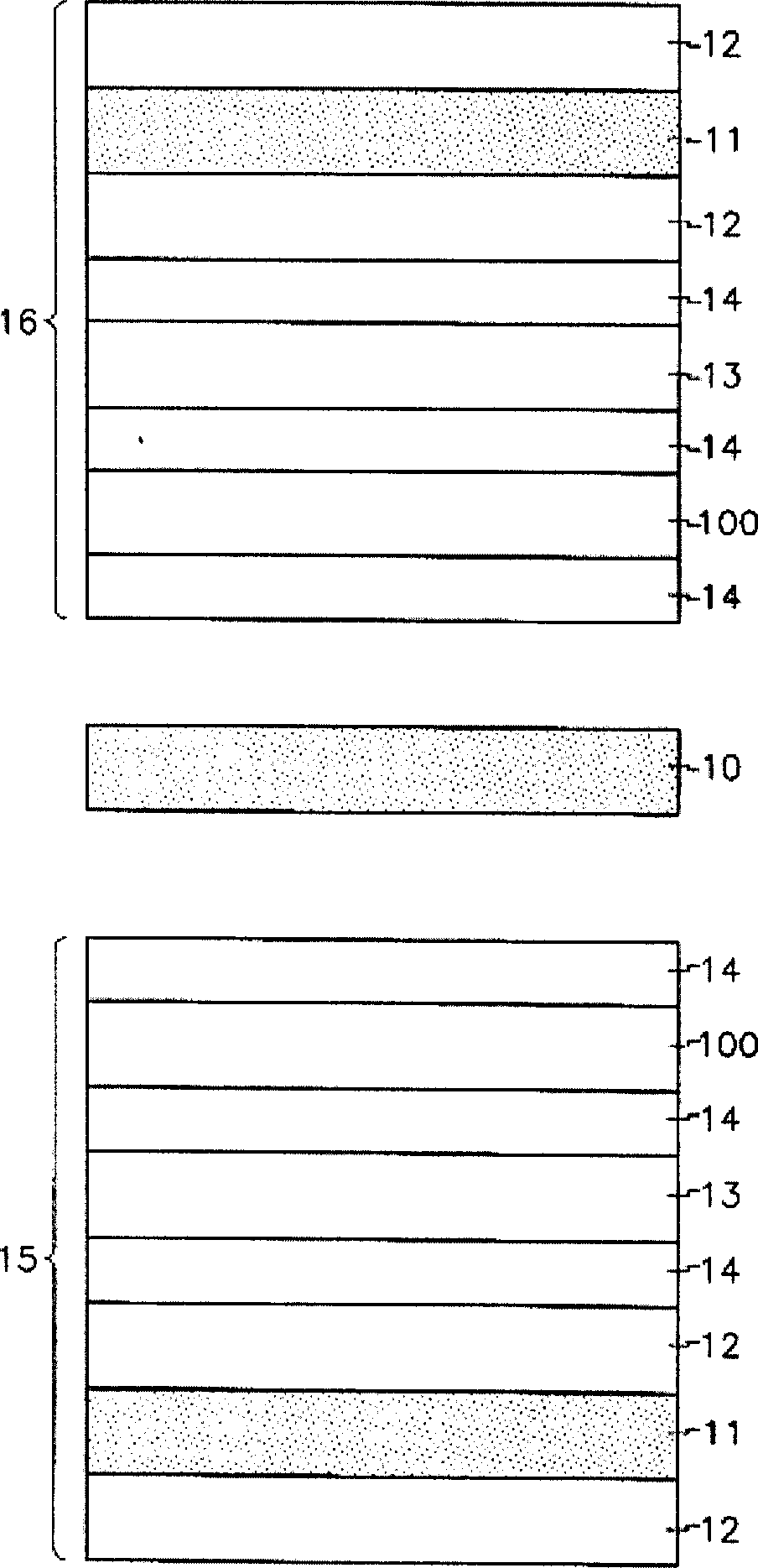

[0204] Such as Figure 4 A structure of a vertical alignment type liquid crystal display (VA-LCD) including a polynorbornene-based polymer film serving as a protective film of a lower polarizing plate and a negative C plate was fabricated. exist Figure 4 Among them, the reference symbol a is the absorption axis of the polarizing plate, and the reference symbol b is the slow axis of the A plate.

[0205] The VA panel includes a VA cell with a 3 μm gap and a pretilt of 89 degrees and filled with a liquid crystal having a negative dielectric anisotropy of Δε=−4.9 and a birefringence of Δn=0.099. Thickness retardation value of VA panel (R VA (550nm)) is 297nm.

[0206] The lower polarizing plate consists from bottom to top: an outer protective film made of TAC polymer, a polarizing film formed by dyeing a PVA film with iodine and then stretching, polynorbornene used as an inner protective film and a negative C plate film Base polymer film, and A-plate film made of polycarbona...

Embodiment 3

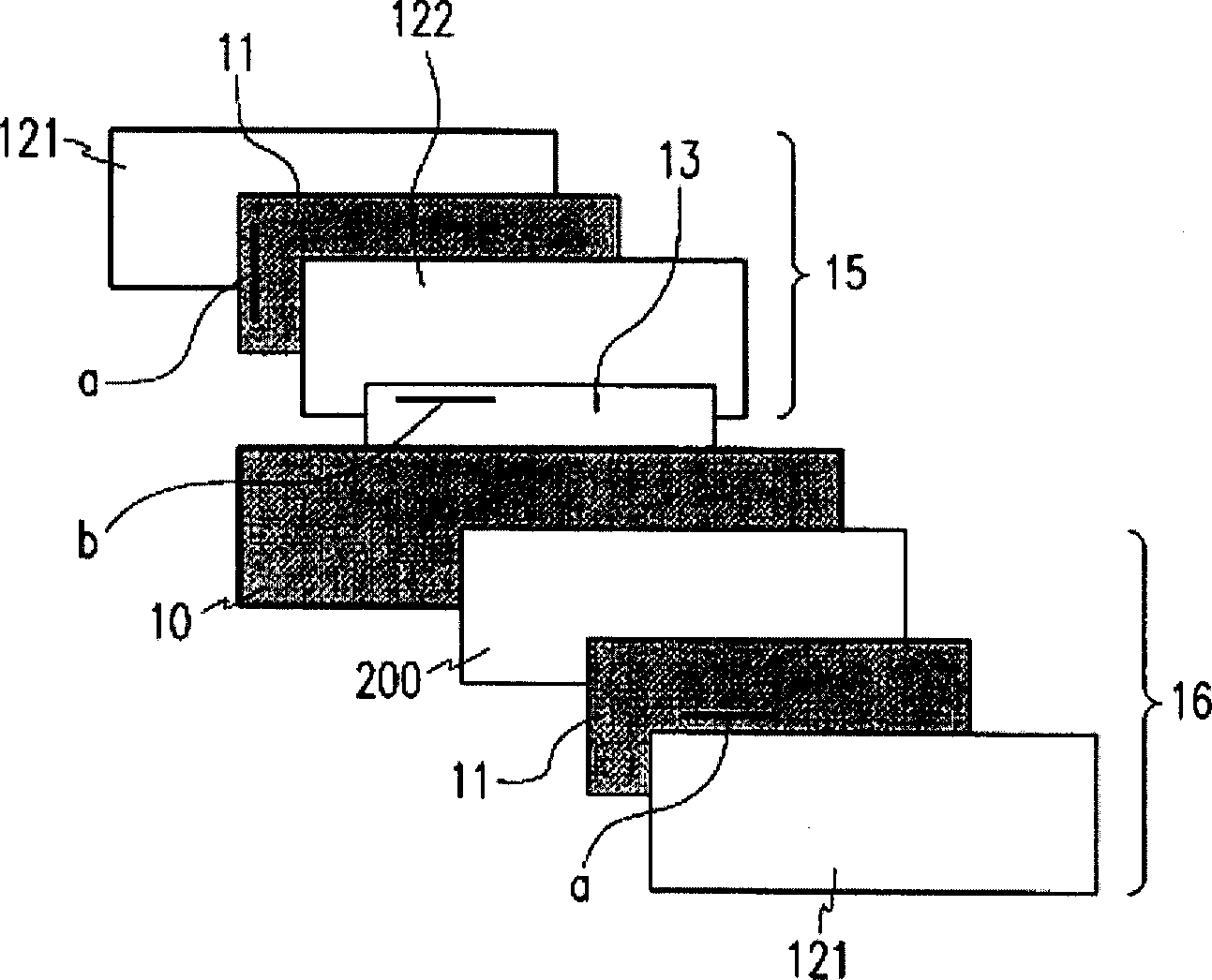

[0210] Such as Figure 5 A vertical alignment type liquid crystal display (VA-LCD) including a polynorbornene-based polymer film serving as an inner protective film of an upper polarizing plate and a lower polarizing plate and a negative C plate was fabricated. exist Figure 5 Among them, the reference symbol a is the absorption axis of the polarizing plate, and the reference symbol b is the slow axis of the A plate.

[0211] The VA panel includes a VA cell with a 3 μm gap and a pretilt of 89 degrees and filled with a liquid crystal having a negative dielectric anisotropy of Δε=−4.9 and a birefringence of Δn=0.099. Thickness retardation value of VA panel (R VA (550nm)) is 297nm.

[0212] The lower polarizing plate consists from bottom to top: an outer protective film made of TAC polymer, a polarizing film formed by dyeing a polyvinyl alcohol (PVA) film with iodine and then stretched, used as an inner protective film, and a negative C plate The polynorbornene-based polymer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| visible light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com