High temperature and high damping resistant rubber composite using polynorbornene rubber as main body

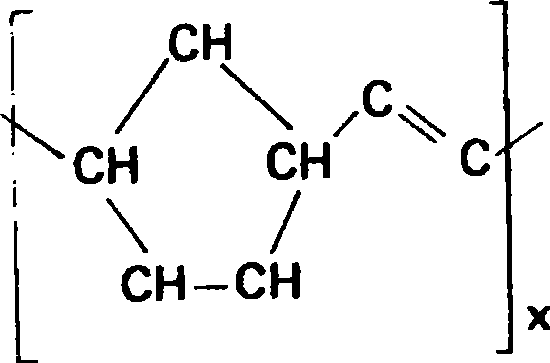

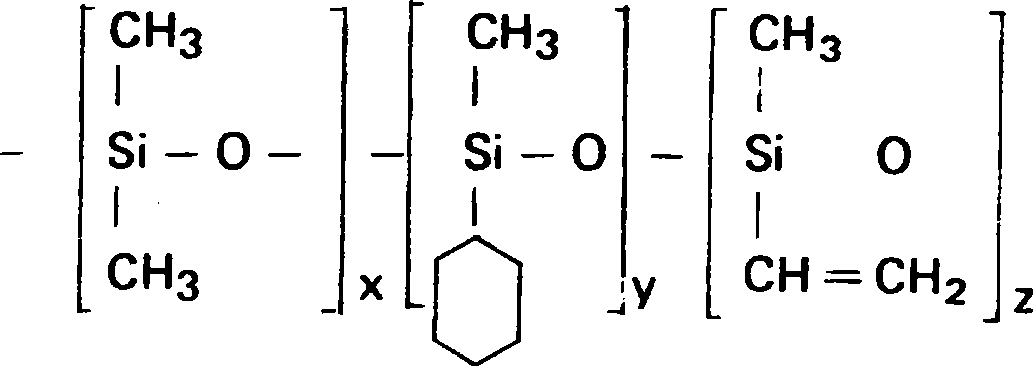

A polynorbornene and rubber composition technology is applied in the field of rubber compositions for rubber products, and can solve the problems of poor ozone aging resistance and unsatisfactory high temperature resistance of polynorbornene rubber, and achieve vibration reduction and reduction. The noise effect is obvious, the reflection is good, and the effect is easy to popularize and apply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

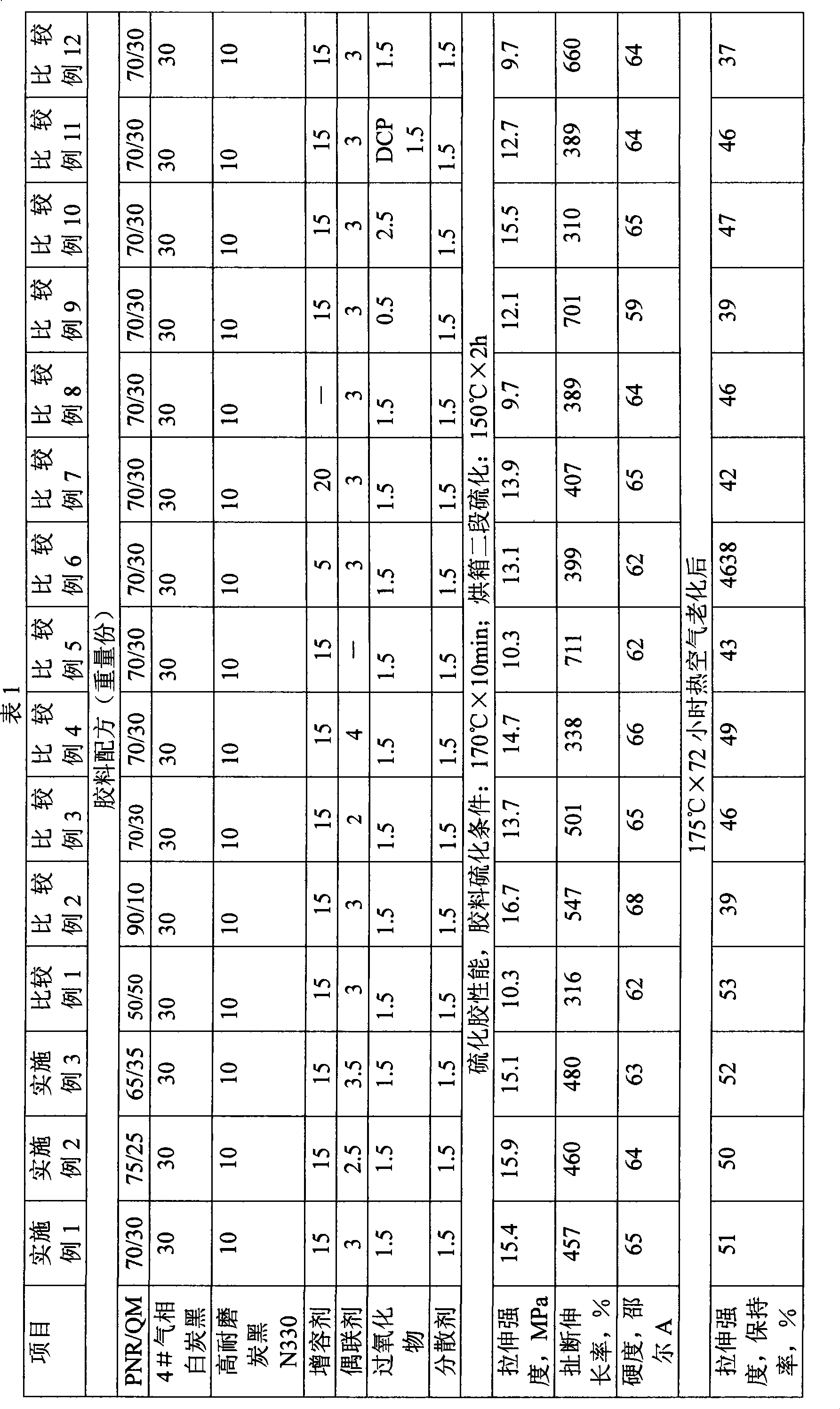

Embodiment 1~3 and comparative example 1~12

[0020] The composition (rubber) formulations of Examples 1 to 3 and Comparative Examples 1 to 12 are all listed in Table 1, and the amount of each compounding component is in parts by weight, wherein, PNR is polynorbornene rubber, and QM is silicone rubber (In this example, methyl vinyl silicone rubber is used); the compatibilizer is a 1:1 (by weight) blend of EPDM rubber and ethylene-methyl acrylate copolymer; the coupling agent is vinyl triacetyl Oxysilane (A-151); peroxide is 2,5-dimethyl-2,5-(tert-butylperoxy)hexane [bis-2,5], DCP in Comparative Example 11 is peroxide Dicumyl oxide; dispersant is AF-52 produced by German Rheinland Chemical Company. All rubber materials except Comparative Example 12 were mixed with a 130°C internal mixer, and then added a vulcanizing agent (peroxide) with an open mixer at room temperature. Comparative example 12 adopts internal mixer normal temperature mixing process. Comparative Examples 1 and 2 are that the blending ratio of two kinds o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com