Pressurizing oil tank of concrete pump

A technology for concrete pump trucks and pressurized fuel tanks, which is applied in the direction of fuel supply tank devices, charging systems, machines/engines, etc. It can solve the problems of reduced fatigue resistance and poor stress on fixed turrets, and achieve structural Simple, improve the oil absorption environment, and improve the effect of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

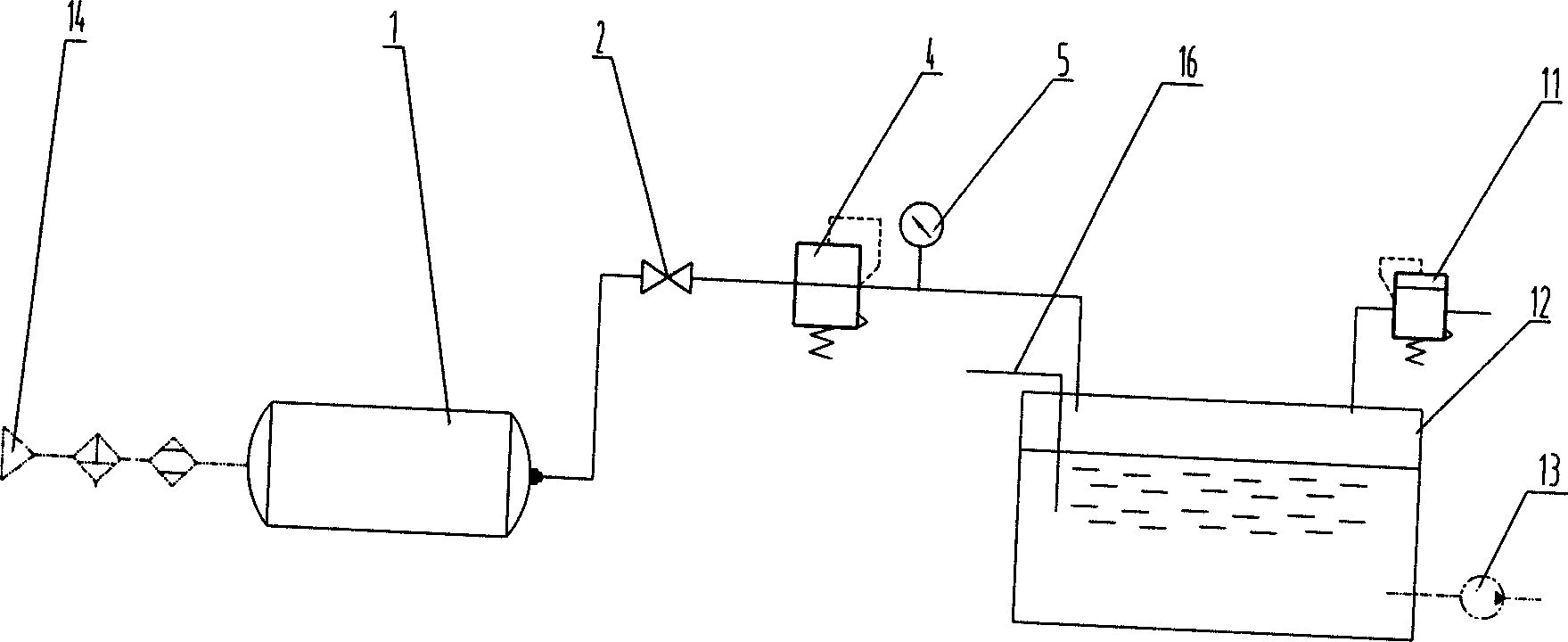

[0029] Embodiment 1: The pressurized oil tank 12 of the concrete pump truck of the present invention is arranged in the fixed turret on the concrete pump truck, and the fixed turret is installed on the auxiliary beam 15 of the pump truck. The fuel tank 12 is fully sealed, and the fuel tank 12 is provided with There are air inlet, oil suction port and oil return port. The oil suction port of the oil tank 12 is connected with the oil pump 13 installed between the beam 15 and the beam 17 of the concrete pump truck through the oil circuit. The safety valve 11 is installed on the oil tank 12. The safety valve 11 It can be used for exhaust when the pressure reducing valve 4 fails or the pipeline is blocked or the air pressure is too high. The air inlet of oil tank 12 links to each other with the air storage tank 1 that is installed on the outside of concrete pump truck chassis frame 17 through air supply device. The gas supply device includes a valve 2, a pressure reducing valve 4 a...

Embodiment 2

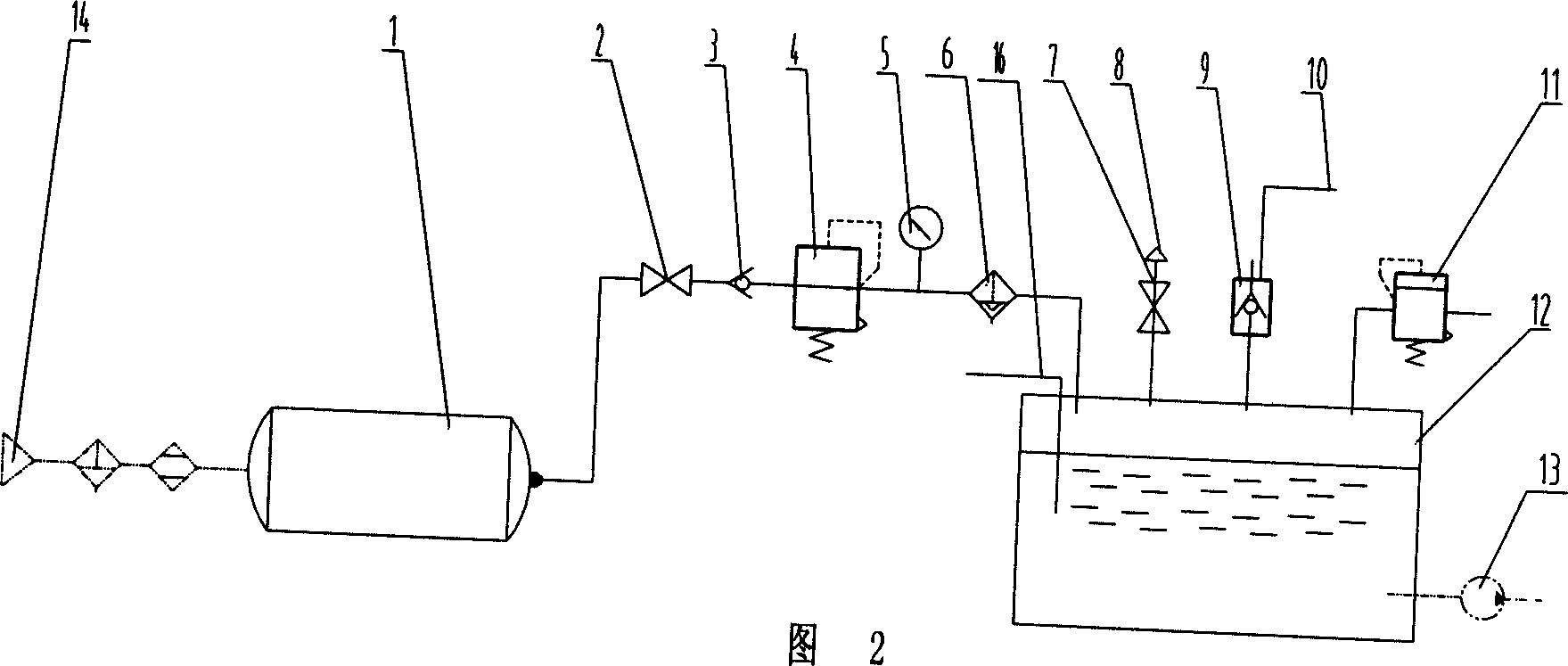

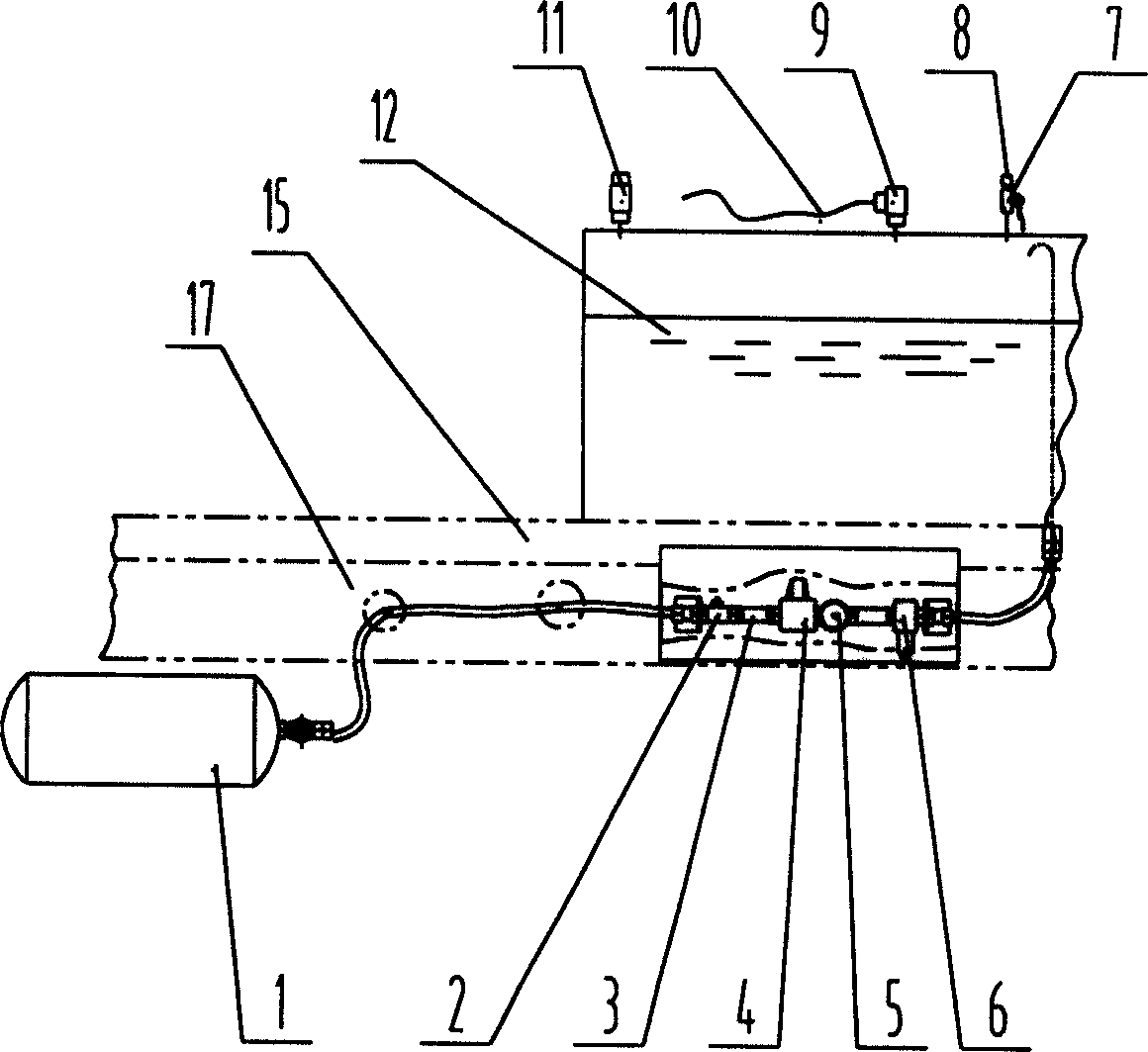

[0031] Embodiment 2: as shown in Figure 2 and image 3 As shown, the pressurized fuel tank 12 of the concrete pump truck of the present invention is arranged in the fixed turret on the concrete pump truck, and the fixed turret is installed on the pump truck beam 15. The fuel tank 12 is fully sealed, and the fuel tank 12 is provided with The air inlet, the oil suction port and the oil return port, the oil suction port of the oil tank 12 is connected with the oil pump 13 installed between the beam 15 and the beam 17 of the concrete pump truck through the oil circuit, and the safety valve 11 is installed on the oil tank 12, and the safety valve 11 can It is used for exhaust when the pressure reducing valve 4 fails or the pipeline is blocked or the air pressure is too high. The air inlet of oil tank 12 links to each other with the air storage tank 1 that is installed on the outside of concrete pump truck chassis frame 17 through air supply device. The air supply device includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com